Method of hydro-conversion of polycyclic aromatic hydrocarbons

A technology for polycyclic aromatic hydrocarbons and hydroconversion, which can be used in hydrotreating process, treatment of hydrocarbon oil, petroleum industry, etc., and can solve the problem of high hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

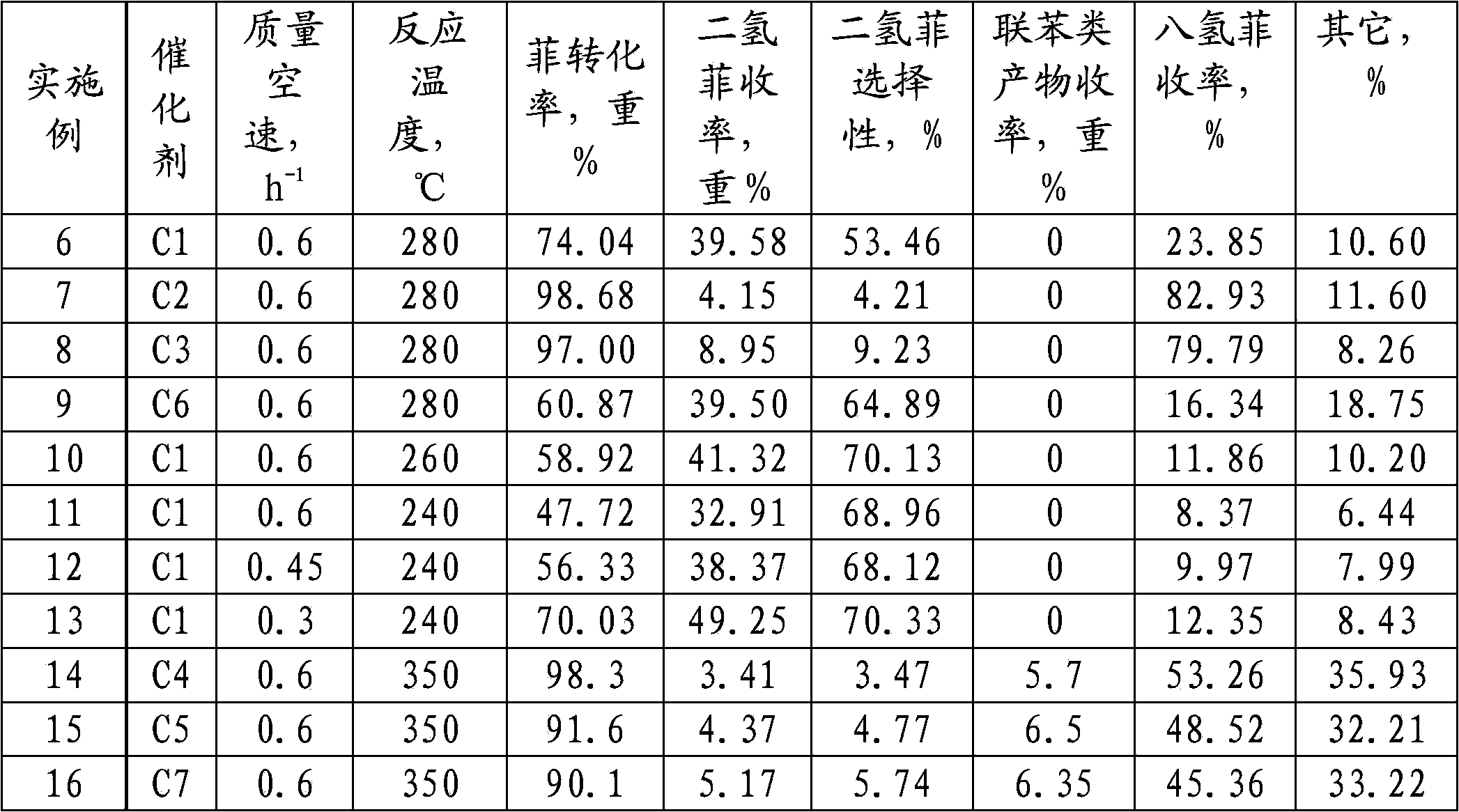

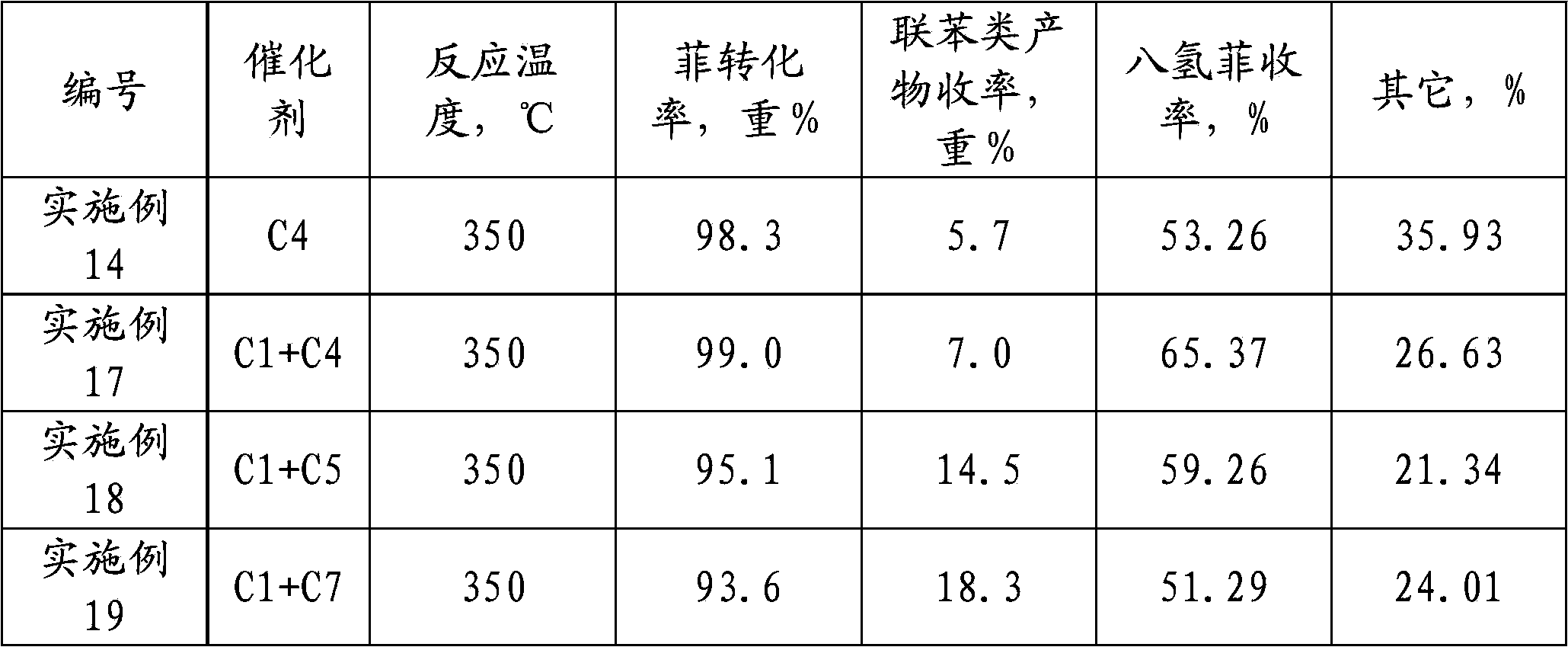

Examples

Embodiment 1

[0041]Weigh 11.8 grams of cobalt nitrate and 17.4 grams of ammonium heptamolybdate, and make 110 milliliters of co-immersion solution with deionized water. Use this solution to impregnate 100 grams of clover-shaped alumina strip carrier S1 with a circumscribed circle diameter of 1.4 mm from Changling Catalyst Branch Company (calcined at 600°C for 4 hours) for 6 hours, then dried at 120°C for 4 hours, and calcined at 420°C for 4 hours , to obtain catalyst C1. Measured by X-ray fluorescence spectrometry, the catalyst C1 contains 2.4% by weight of CoO, containing MoO 3 It is 12.0% by weight.

Embodiment 2

[0043] Weigh 11.7 grams of nickel nitrate and 17.4 grams of ammonium heptamolybdate, and make 110 milliliters of co-immersion solution with deionized water. 100 g of S1 carrier was impregnated with this solution for 6 hours, then dried at 120° C. for 4 hours, and calcined at 420° C. for 4 hours to obtain catalyst C2. Measured by X-ray fluorescence spectrometry, the catalyst C2 containing NiO is 2.4% by weight, containing MoO 3 It is 12.0% by weight.

Embodiment 3

[0045] Weigh 9.55 grams of nickel nitrate and 25.7 grams of ammonium metatungstate, and make 110 milliliters of co-immersion solution with deionized water. 100 g of S1 carrier was impregnated with this solution for 6 hours, then dried at 120° C. for 4 hours, and calcined at 420° C. for 4 hours to obtain catalyst C3. Measured by X-ray fluorescence spectrometry, the catalyst C3 containing NiO is 1.8% by weight, containing WO 3 It is 18.5% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com