Coupling method and system for low-temperature methanol washing technology and CO2 compressing technology

A low-temperature methanol washing, CO2 technology, applied in chemical instruments and methods, petroleum industry, carbon compounds, etc., can solve the problems of reducing operating costs, unreasonable energy utilization, and high process energy consumption, saving power consumption and improving energy utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

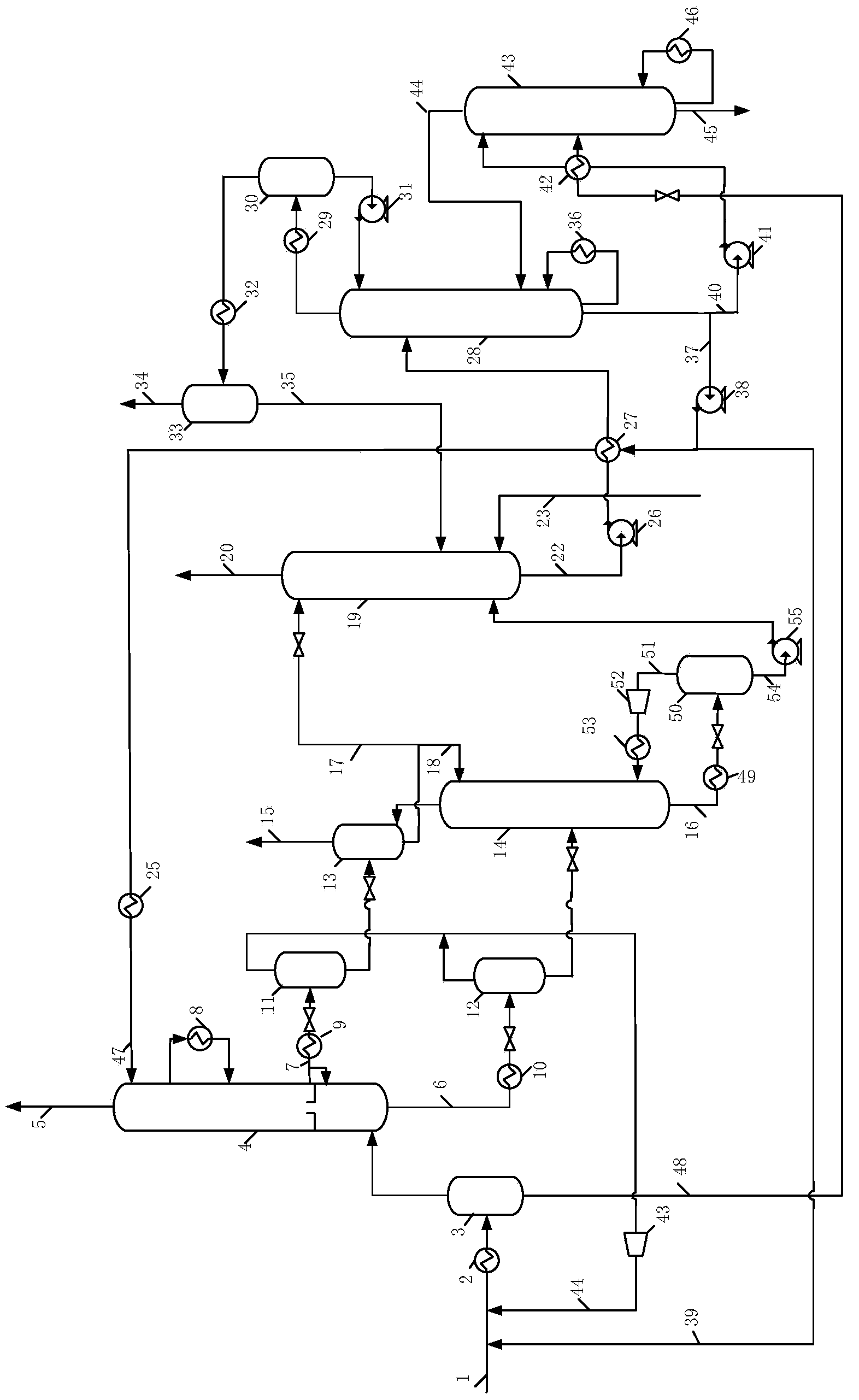

[0047] see figure 2 , the low-temperature methanol washing process of this embodiment and the CO 2 The coupling method of the compression process includes the following steps:

[0048] (1) Methanol barren solution 37 and H 2 The methanol rich liquid 22 and the CO at the bottom of the S concentration tower 19 2 The methanol rich liquid 16 at the bottom of the desorption tower 14 is transported to the top of the acid gas absorption tower 4 after heat exchange and cooling respectively;

[0049] (2) CO 2 After the methanol-rich liquid 16 at the bottom of the desorption tower 14 and the methanol-poor liquid 37 are heat-exchanged and heated, they are then mixed with CO 2 CO-enriched at the top of flash tower 50 2 Gas 51 conducts heat exchange to raise the temperature, and then with CO 2 Compressed CO at the end of a multi-stage compression unit 2 The product gas 66 is coupled and heated through a heat exchanger, and finally sent into the CO 2 Flash tower 50.

[0050] The l...

Embodiment 2

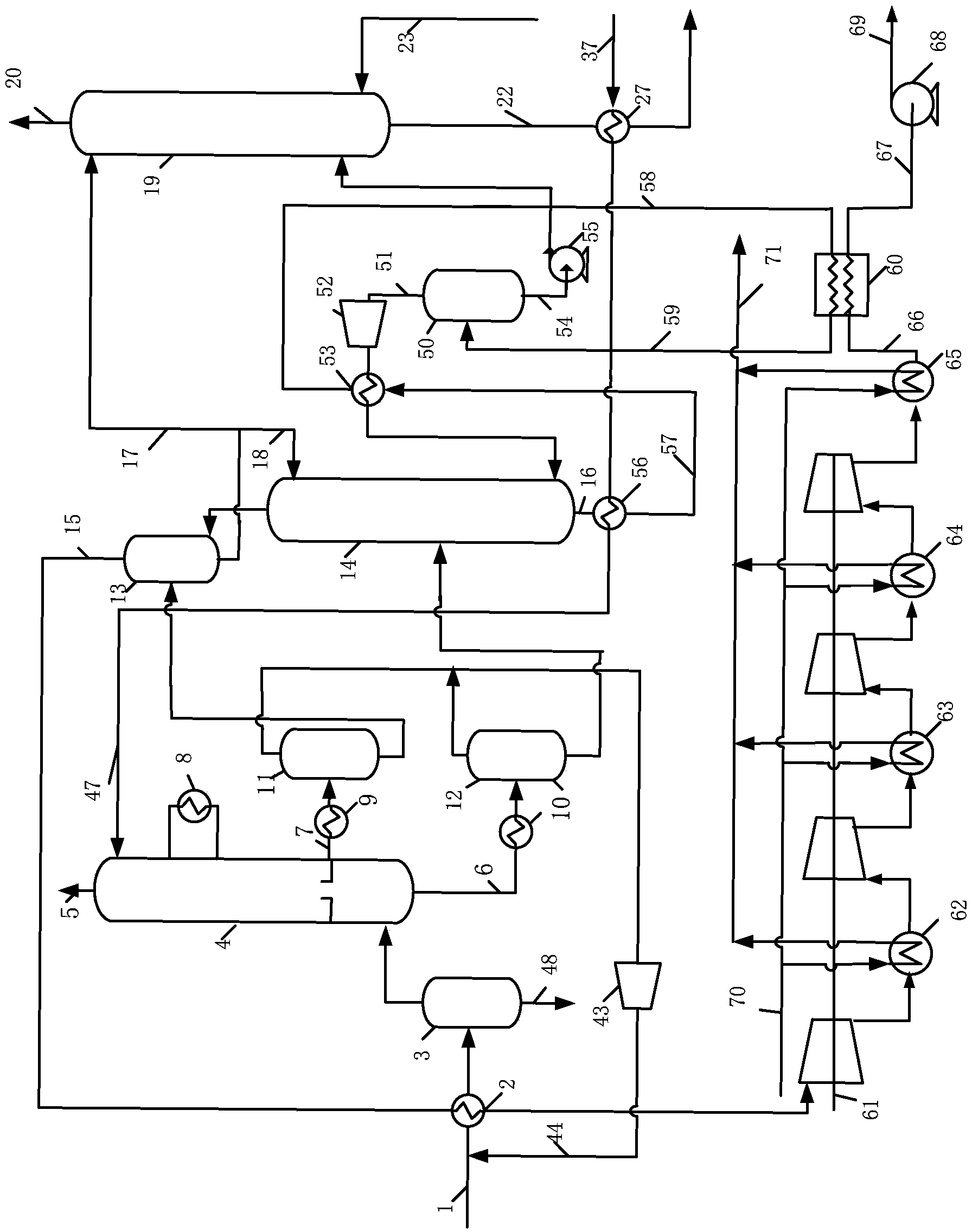

[0060] The low-temperature methanol washing process of the present embodiment and the CO 2 The coupling method and system of the compression process are the same as in Embodiment 1, the difference is that: CO 2 Yields vary and therefore corresponding operating temperatures also vary. details as follows:

[0061] see figure 2 , CO 2 The methanol-rich liquid 16 at the bottom of the desorption tower 14 enters the CO 2 Before the flash tower 50, it passes through heat exchangers 56, 53, and 60 to fully recover and utilize the low-temperature cooling capacity generated in the desorption process. After passing through heat exchanger 56, the operating temperature is -33°C, and after passing through heat After that, the operating temperature is -26°C, after passing through the heat exchanger 60, the operating temperature is -5°C, CO 2 The operating pressure of the flash column 50 is 1.7 bar. CO 2 CO rich 2 Gas 51 is transported to CO after being pressurized and cooled 2 At ...

Embodiment 3

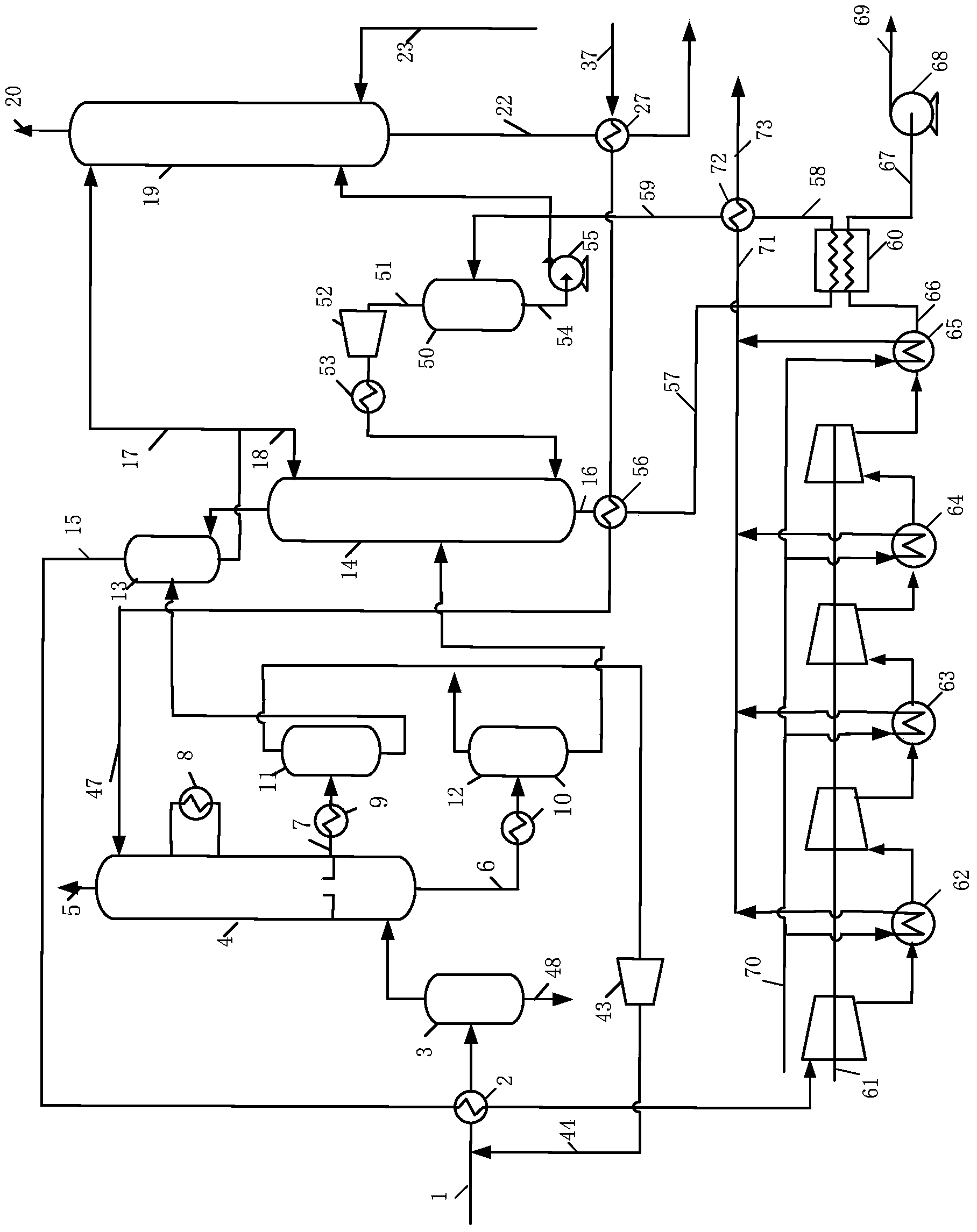

[0065] see image 3 , the low-temperature methanol washing process of this embodiment and the CO 2 The coupling method of the compression process includes the following steps:

[0066] (1) Methanol barren solution 37 and H 2 The methanol rich liquid 22 and the CO at the bottom of the S concentration tower 19 2 The methanol rich liquid 16 at the bottom of the desorption tower 14 is transported to the top of the acid gas absorption tower 4 after heat exchange and cooling respectively;

[0067] (2) CO 2 After the methanol-rich liquid 16 at the bottom of the desorption tower 14 and the methanol-poor liquid 37 are heat-exchanged and heated, they are then mixed with CO 2 Compressed CO at the end of a multi-stage compression unit 2 The product gas 66 is coupled to heat up through a heat exchanger, and then with CO 2 The circulating water hot end 71 in the multi-stage compression device performs heat exchange to raise the temperature, and finally sends the CO 2 Flash tower 50. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com