Method for utilizing cold energy of low-temperature ethylene during VCM preparation through ethylene balanced oxychlorination method

A technology of oxychlorination and ethylene, applied in chemical instruments and methods, preparation of halogenated hydrocarbons, chemical industry, etc., can solve problems such as ineffective use of liquid ethylene cold energy, no use of cold energy, and large steam consumption, etc., to achieve Reduce equipment maintenance costs, save electricity, and save steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

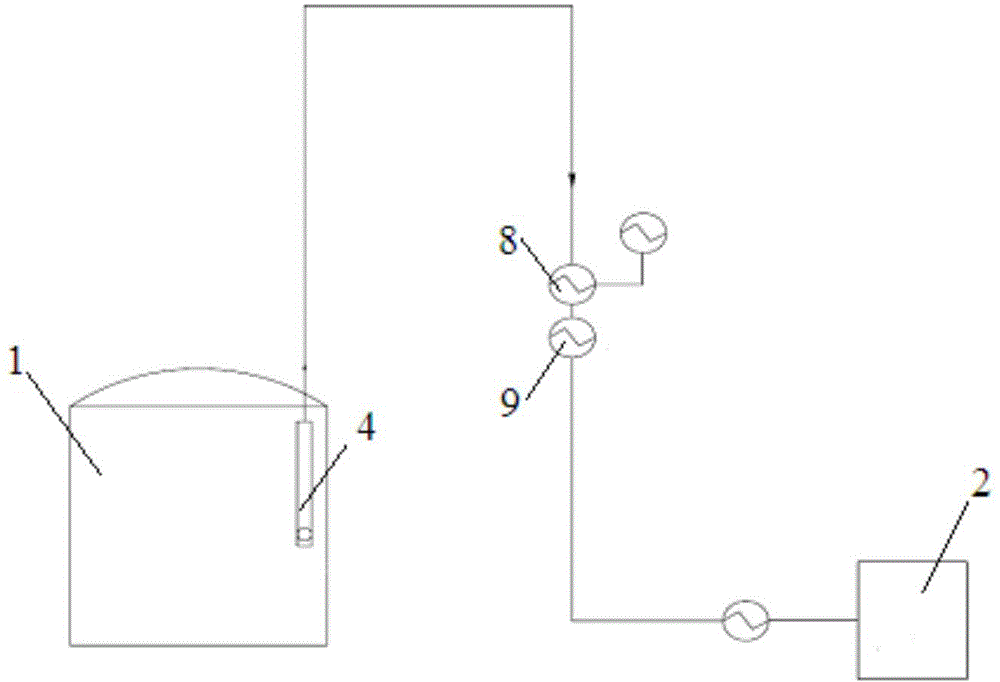

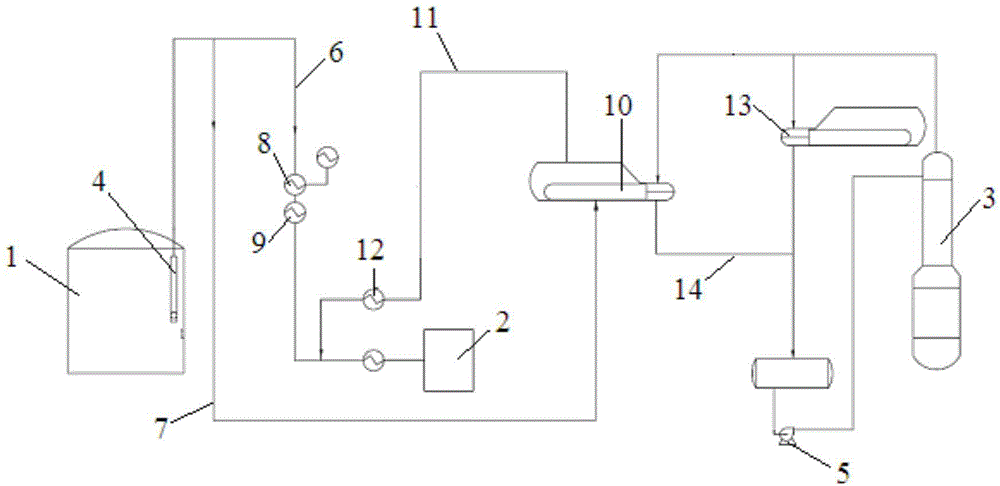

[0050] Reference attached figure 2 An ethylene vaporization process device for preparing vinyl chloride by an ethylene equilibrium oxygen-chlorine method comprises a liquid ethylene storage tank 1, a chlorine oxidation reactor / chlorination reactor 2, a hydrogen chloride tower 3, and delivery pumps (4, 5). Liquid ethylene at -103°C is stored in the ethylene storage tank 1 for standby use. The liquid ethylene storage tank 1 is provided with a pump 4 to facilitate the output of the liquid liquid. The liquid ethylene flows out of the liquid ethylene storage tank 1 in two ways. The first ethylene stream flows into the chlorination reactor / chlorine oxidation reactor 2 through the first pipeline 6, and two heat exchangers (8,9) are arranged on the pipeline 6, and the heat medium of the heat exchanger can be selected for use commonly used in this field Substances such as methanol vapor, etc., make liquid ethylene at a temperature of -103°C heat up to vaporize into ethylene at -26°C t...

experiment example 1

[0055] This embodiment is based on the equipment of Embodiment 1 of the present invention. By utilizing the cold energy of ethylene, the energy saving is as follows: Other processes and process parameters refer to the prior art. The difference is that the ethylene vaporization process is different.

[0056] According to 400,000 tons / year VCM, vinyl chloride is 50,000kg / h, and the amount of hydrogen chloride produced is 28,432kg / h. If 50% of the hydrogen chloride condensation is designed to be realized by the cold energy of low-temperature ethylene, the calculation is as follows:

[0057] The cooling energy required for the liquefaction of gaseous hydrogen chloride at the top of the hydrogen chloride tower at -35°C is:

[0058] Q 1 =mr=28432kg / h×50%×91.7kcal / kg=1303607.2kcal / h

[0059] Therefore, the cooling energy to be provided by the ethylene vaporizer is:

[0060] Q 2 =Q 1 =1303607.2kcal / h

[0061] According to the pipe network pressure and the condensation temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com