High cleanness diesel component

A clean and diesel technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of high content of particulate matter, nitrogen oxides and hydrocarbons, incomplete combustion of diesel, environmental hazards, etc., to improve environmental friendliness The effect of safety, low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

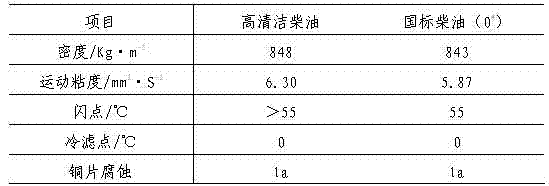

Embodiment 1

[0017] Add 50kg of fatty acid methyl ester, 30kg of pentanol and 18kg of polymethoxy formal into the stirring tank, stir and mix evenly at 20°C, then add 1kg of n-butyl oxalate and 1kg of metal deactivator, and continue stirring for 15 minutes until The material is clear and transparent. The high-clean diesel component is uniformly mixed with national standard diesel at a mass ratio of 30%, and can be applied to various types of diesel engines.

Embodiment 2

[0019] Add 30kg of fatty acid methyl ester, 30kg of mixed hexanol and 37kg of polymethoxy formal into the stirring tank, stir and mix evenly at 20°C, then add 2kg of n-butyl oxalate and 1kg of metal deactivator, and continue stirring for 15 minutes until The material is clear and transparent. The high-clean diesel component is evenly mixed with national standard diesel at a mass ratio of 40%, which can be applied to various types of diesel engines.

Embodiment 3

[0021] Add 40kg of fatty acid methyl ester, 19kg of pentanol and 40kg of polymethoxy formal into the stirring tank, stir and mix evenly at 20°C, then add 0.5kg of n-butyl oxalate and 0.5kg of metal deactivator, and continue stirring for 15 minutes , until the material is clear and transparent. The high-clean diesel component is uniformly mixed with national standard diesel at a mass ratio of 50%, and can be applied to various types of diesel engines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com