Automatic control system for copper converter converting

A converter blowing and control system technology, applied in the field of copper concentrate smelting, can solve the problems of frequent tilting of the furnace body, inaccurate judgment of the end point, and low hit rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

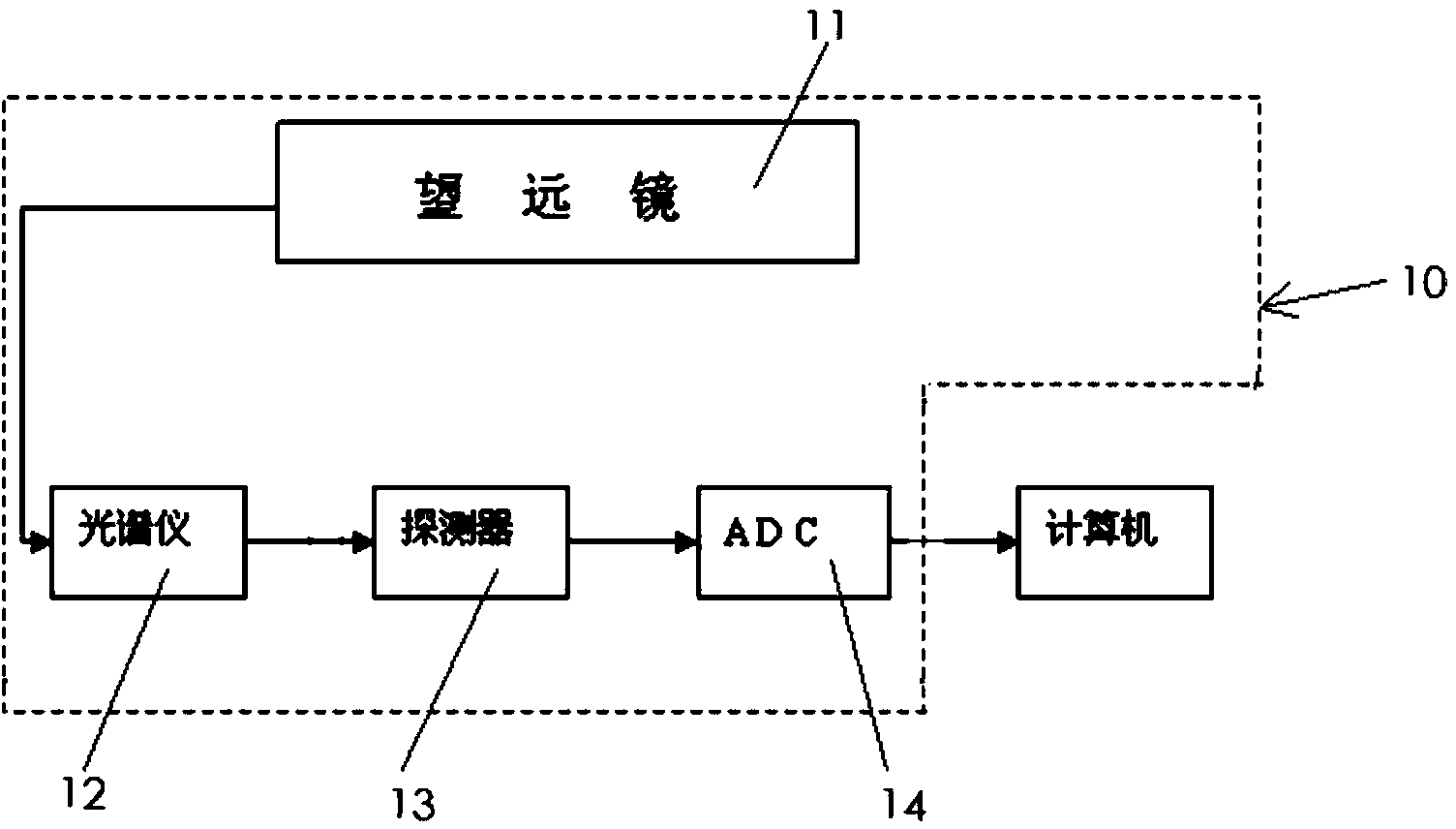

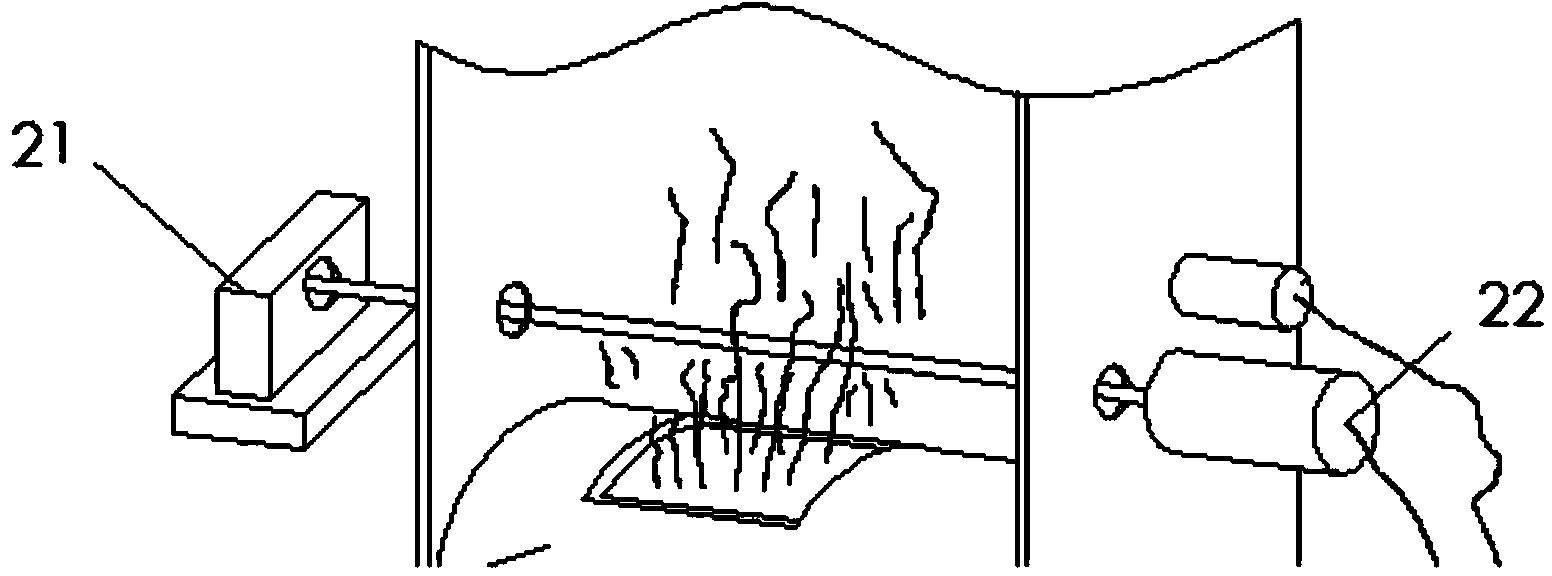

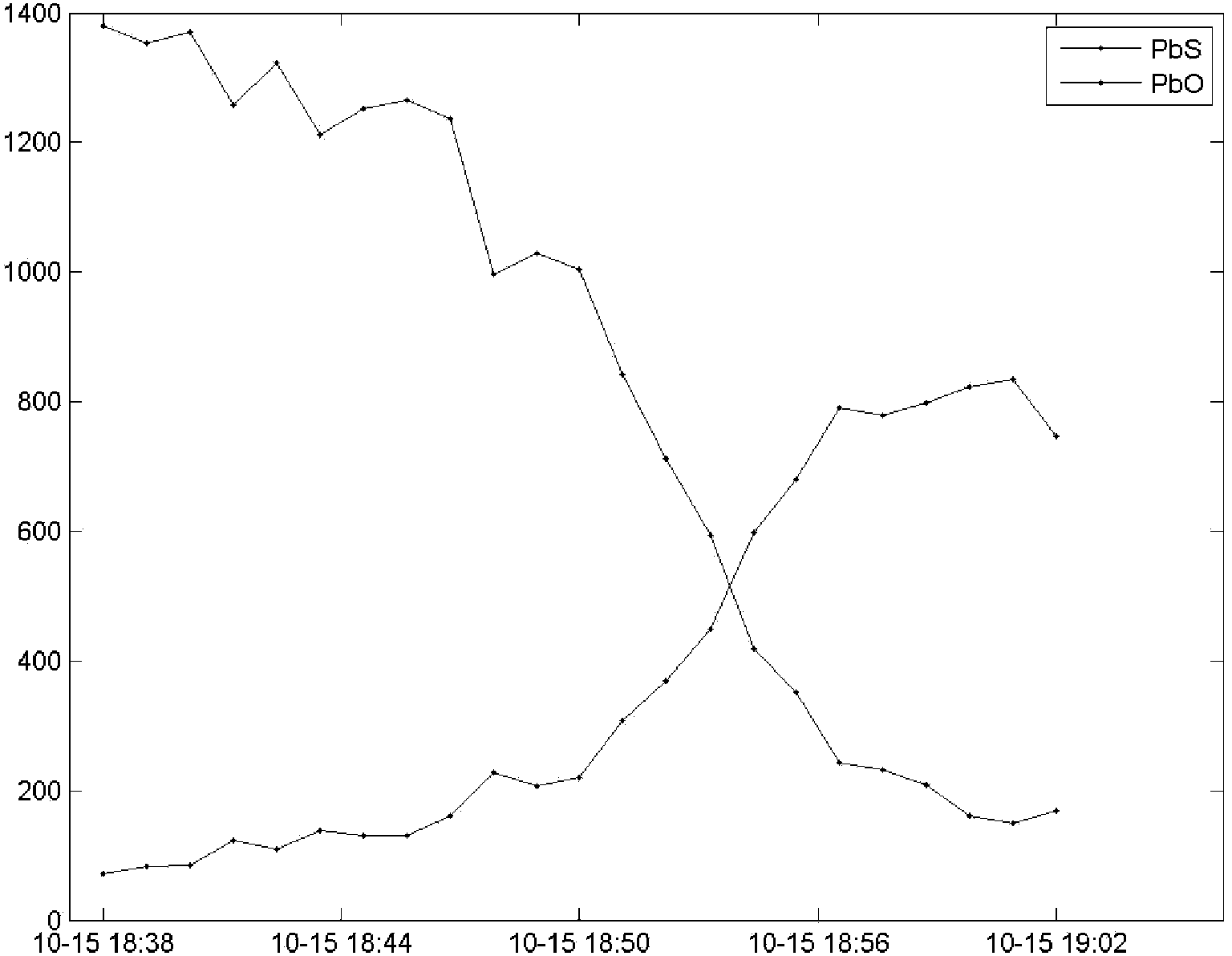

[0015] The control system for copper converter blowing provided by the present invention includes a slagging end point detection unit 10 for signal acquisition of the emission intensity of PbO and PbS characteristic spectra in the melt in the copper converter online during the slagging period, and an online SO in flue gas of copper converter 2 The copper-making end-point detection unit that collects gas concentration signals, and the data processing unit analyzes and processes the signals collected by the slag-making and copper-making end-point detection unit to determine whether it has reached the slag-making and copper-making end points and regulates whether to stop wind blowing. The data processing unit can be composed of a computer to display the analyzed and processed data and results. The operator can manually adjust whether to stop the blowing according to the results, or automatically adjust whether to stop the blowing through the computer control actuator.

[0016] Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com