Thick steel plate with high strength and toughness as well as uniform performance in thickness direction and production method of thick steel plate

A thickness direction, high strength and toughness technology, applied in the field of high strength toughness thick steel plate and its production, can solve the problem of uneven mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below:

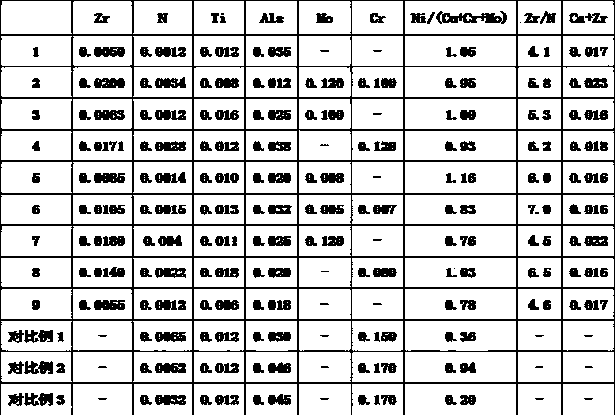

[0040] Table 1 is the value list of each embodiment of the present invention and comparative examples;

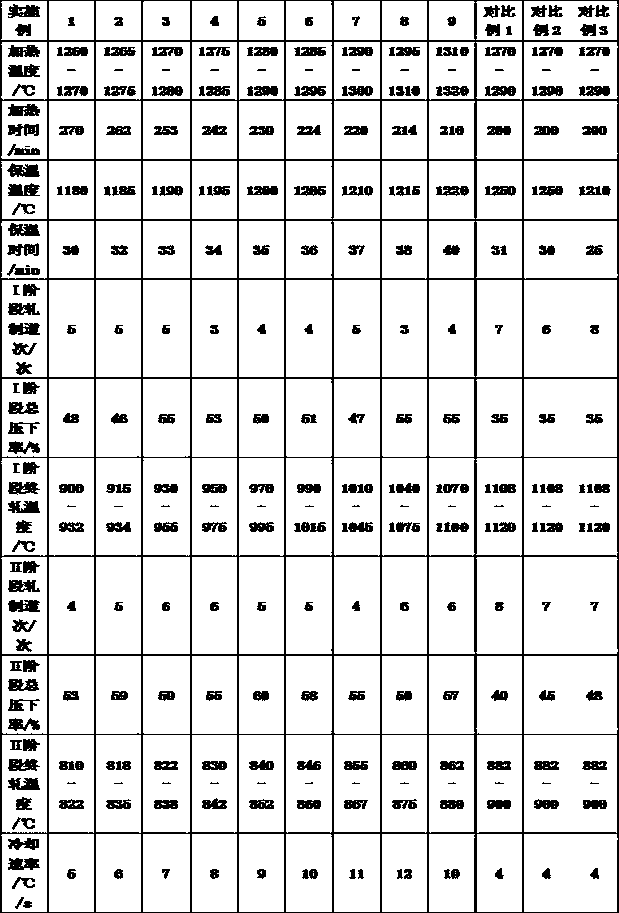

[0041] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

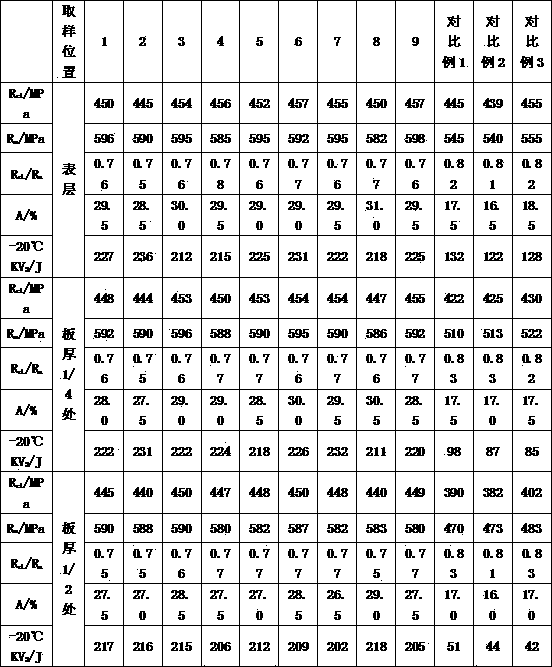

[0042] Table 3 is a list of the performance tests of the various embodiments of the present invention and comparative examples.

[0043] Each embodiment of the present invention is produced according to the following steps:

[0044] 1) Carry out converter smelting, control the temperature of incoming molten iron at 1260-1300°C, the composition of molten iron P≤0.15%, S≤0.002%; control the number of blowing times in the middle of converter smelting to no more than 2 times, and control the end point composition of molten steel: C: 0.05~ 0.07%, P≤0.010%;

[0045] 2) Carry out LF refining, control the temperature of molten steel arriving at the station to not be lower than 1550°C, the refining ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com