A double-drive electroplating workpiece conveyor

A conveyor and dual-drive technology, applied in the field of dual-drive electroplating workpiece conveyors, can solve the problems of electroplating enterprises increasing operating costs, affecting electroplating production efficiency, and pole bars cannot be placed accurately, achieving increased friction, not easy to slide, The effect of reducing the braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

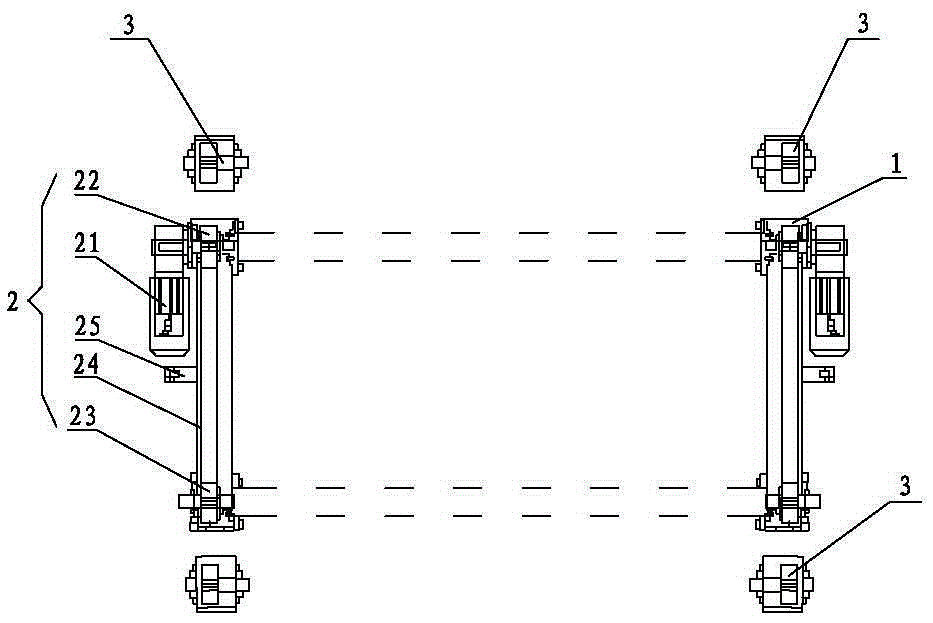

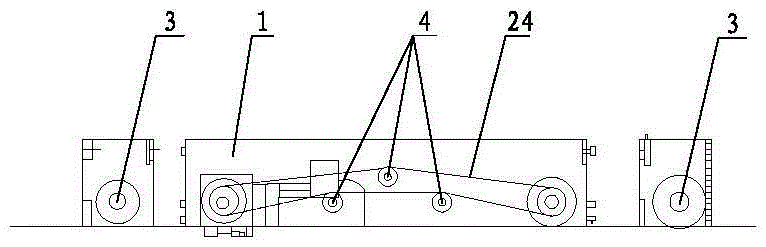

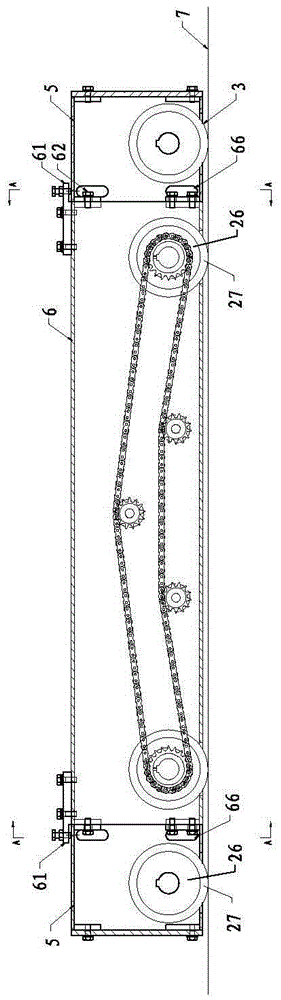

[0044] Such as figure 1 and figure 2 As shown, a dual-drive electroplating workpiece conveyor in this embodiment includes a main structure 1 and a walking system arranged on the main structure 1. The walking system includes a PLC control device and two sets of symmetrically arranged walking mechanisms 2, two sets of The running mechanism 2 is respectively located on both sides of the main structure 1, and the running mechanism 2 includes a geared motor 21, a drive wheel 22, a transmission wheel 23 and a transmission member 24, and the geared motor 21 is driven and connected to the drive wheel 22. The driving wheel 22 and the transmission wheel 23 are connected through the transmission member 24. The running mechanism 2 also includes a positioning piece installed on the walking track and a positioning sensor 25 for sensing the positioning piece. The PLC control device They are electrically connected to the positioning sensor 25 and the geared motor 21 respectively.

[0045]D...

Embodiment 2

[0068] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that an adjustment gear 4 for adjusting the tightness of the transmission member 24 is arranged between the driving wheel 22 and the transmission wheel 23 of this embodiment. A gear 4 is mounted on the main structure 1 .

[0069] After the transmission member 24 has been used for a period of time, it will have a certain deformation due to wear and tear, causing the transmission member 24 to slip or even loosen at the position of the drive wheel 22 and the transmission wheel 23. The setting of the adjustment gear 4 keeps the transmission member 24 always The moderate degree of tightness ensures good transmission effect of the driving wheel 22 and the transmission wheel 23 and prolongs the service life of the transmission member 24 .

[0070] Wherein, there are at least two adjusting gears 4 , and at least two adjusting gears 4 are in contact with the transmission member 24 . Preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com