Epoxy Resin Cement Concrete Constructing Basement External Wall by Blocks and Its Construction Method

A technology of epoxy resin cement and basement exterior walls, which is applied in water conservancy projects, underwater structures, buildings, etc., can solve the problems of difficult maintenance period and harsh maintenance conditions, and achieve excellent waterproof effect, thorough maintenance, and waterproof The effect of slow and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

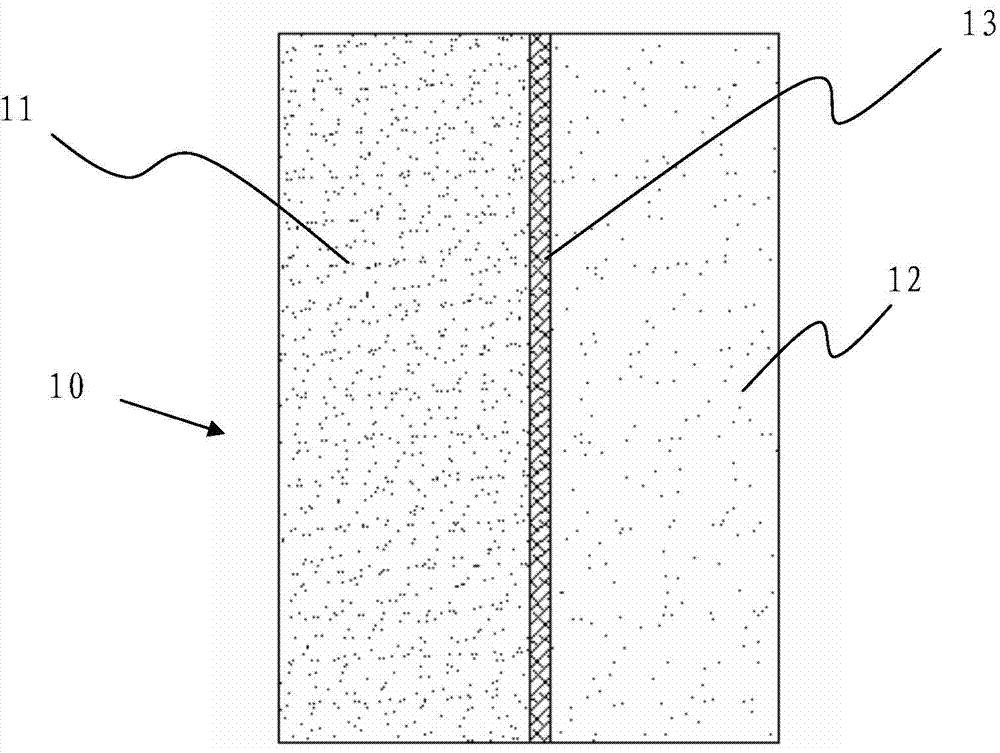

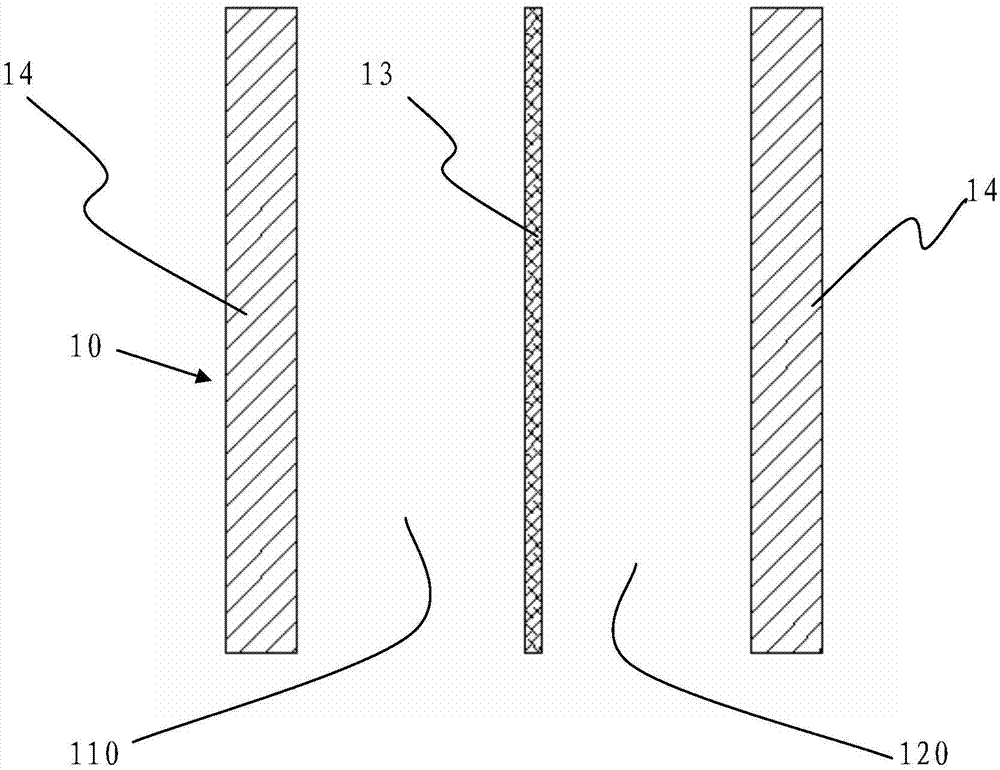

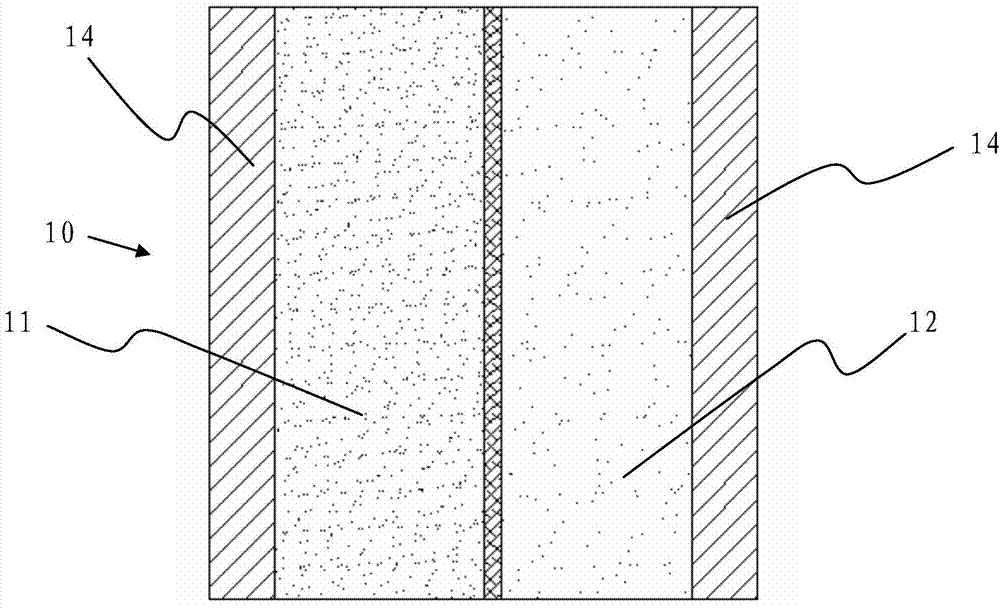

[0018] see first figure 1 As shown, the epoxy resin cement concrete block-casting basement exterior wall of the present invention includes an epoxy resin cement concrete wall 11 relatively close to the water-facing side 10 and a relatively far away from the water-facing side 10 that are poured simultaneously along its thickness direction. The ordinary cement concrete wall 12 is composed of an epoxy resin cement concrete wall 11 and the ordinary cement concrete wall 12, and a layer of fast and easy closing net 13 is arranged between the epoxy resin cement concrete wall 11 and the ordinary cement concrete wall 12. The quick and easy closing net 13 is used as the epoxy resin cement concrete wall 11 and Ordinary cement concrete wall 12 is the separation layer during concrete pouring, and after the concrete pouring is completed, there is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com