Lightweight composite prefabricated panel combined type house and building method thereof

A prefabricated wall panel and combined technology, which is applied in the direction of building structure, floor slab, building, etc., can solve the problems of energy waste, low comfort, and no wall energy-saving measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The structure of the light-weight composite prefabricated wall panel combined house proposed by the present invention will be further described below in conjunction with the accompanying drawings.

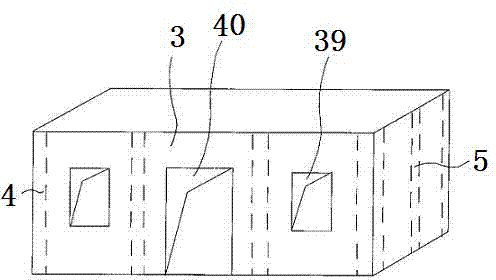

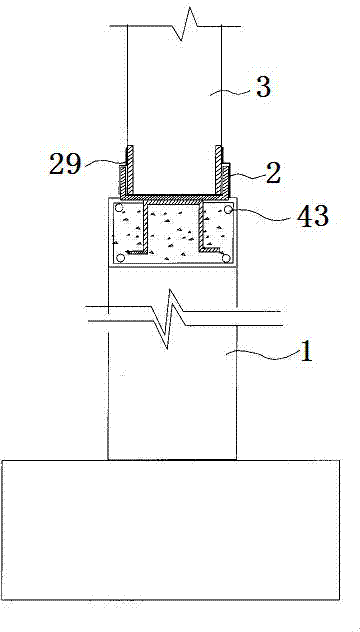

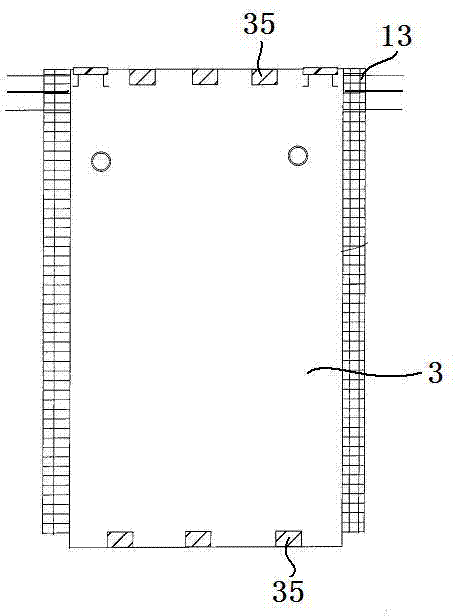

[0055] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 Shown is a structural schematic diagram of a lightweight composite prefabricated wall panel combined house. Its structure includes a foundation 1, at least one layer of prefabricated wall panels 3 is fixed above the foundation 1 through the lower fixture 2, corner columns 4 are arranged at the corner where two prefabricated wall panels 3 intersect, and two peripheral prefabricated walls The joints of the boards 3 are provided with connecting columns 5; the prefabricated wall panels 3 include grid panels 6 and concrete 7, and the grid panels 6 include wall insulation boards 8 and the first steel mesh sheets 9 and The second reinforcem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com