Leaf motor drive -type under well pressure voltage devices and methods

A technology of vane motor and booster device, which is applied in the direction of drilling with liquid/gas jet, can solve the problems of large vibration, shock and wear of internal components, inability to ensure continuous power source, and affect the service life of tools, etc., to achieve small dependence on structure Simple, simple internal structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

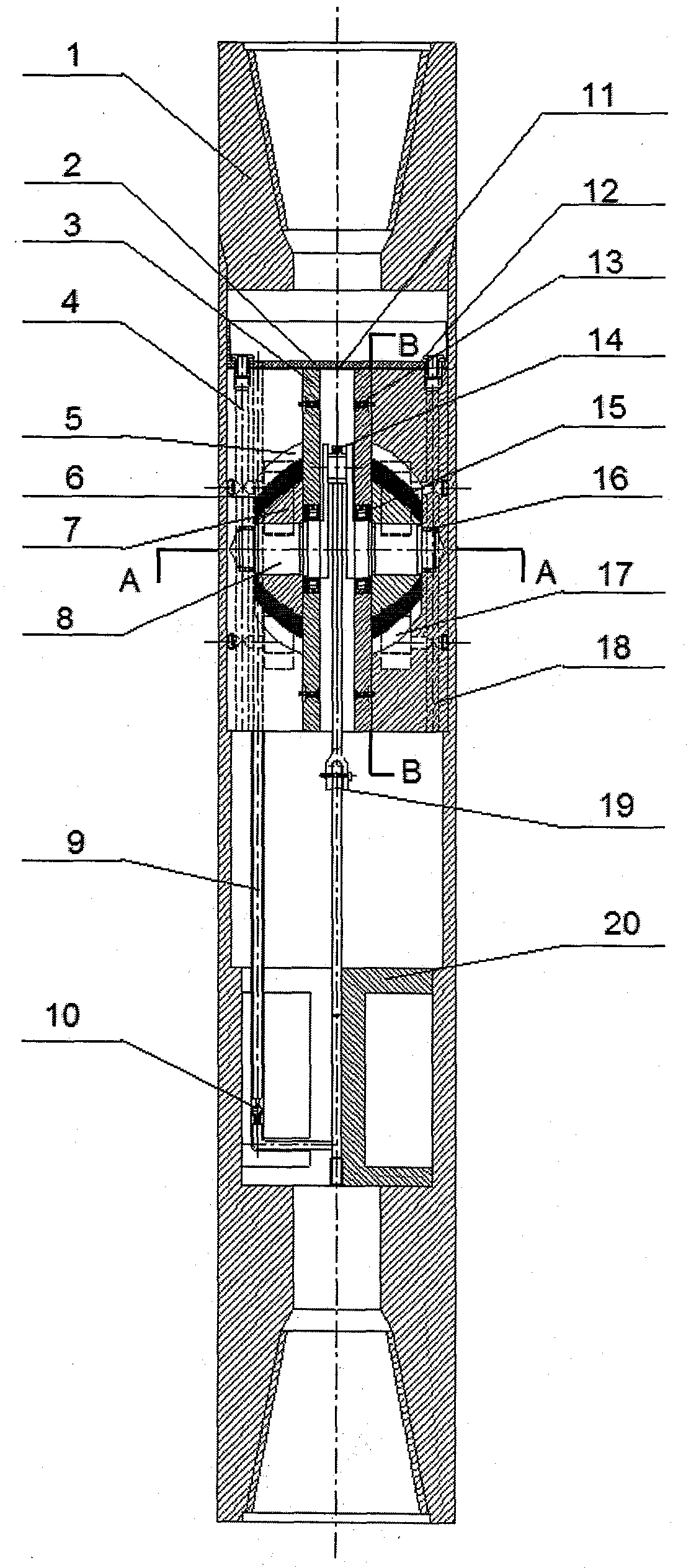

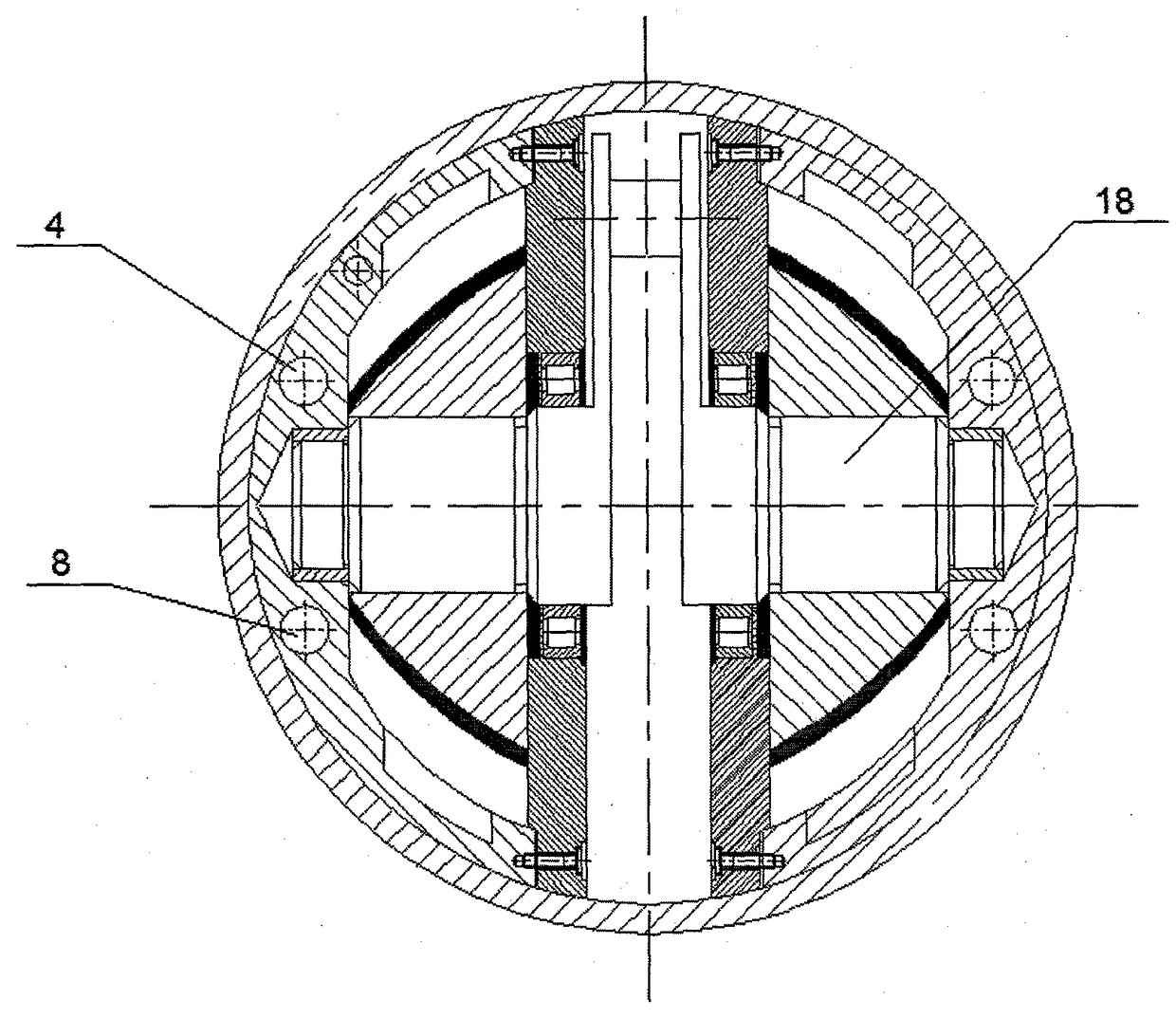

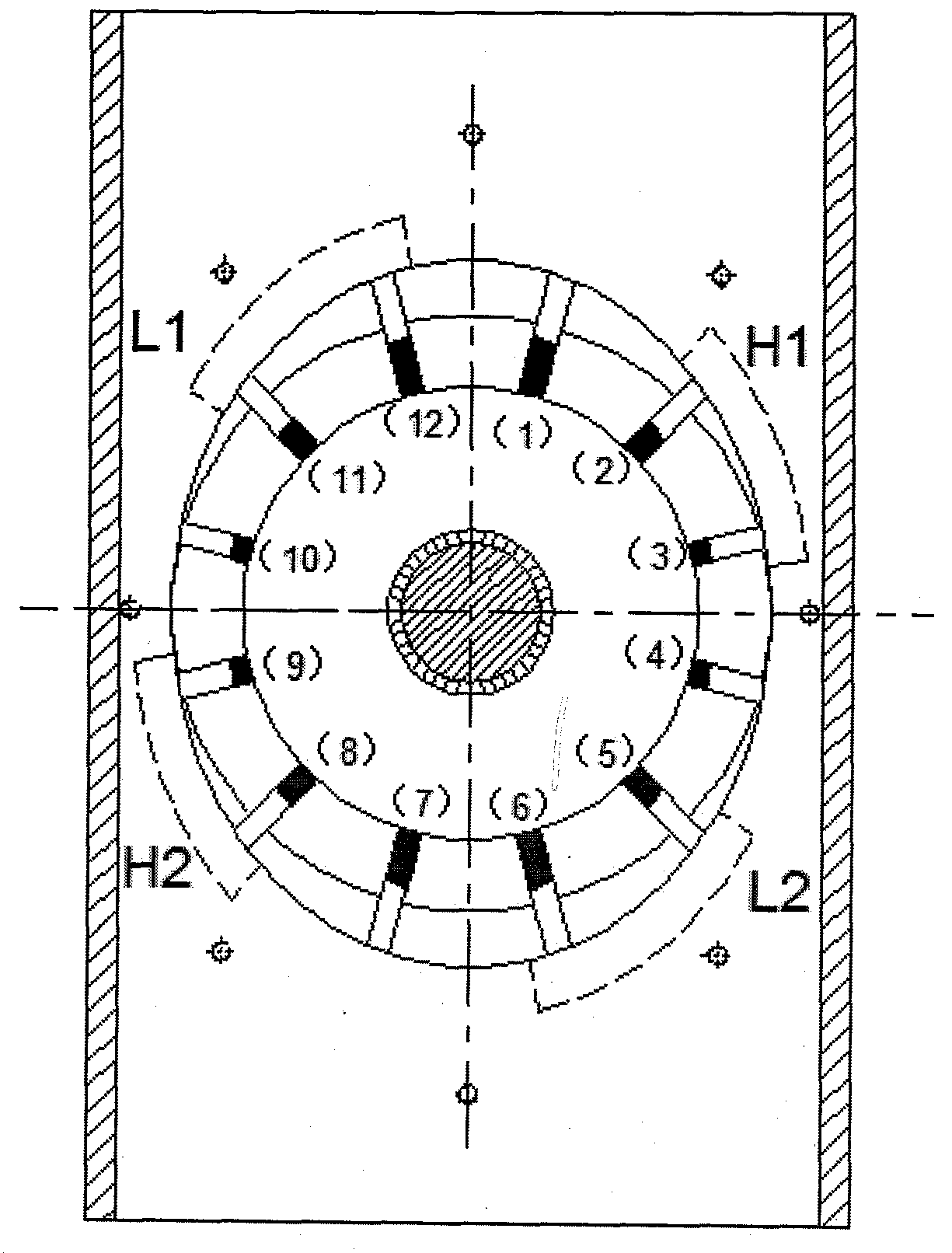

[0024] exist figure 1 Among them, the upper end of the casing (1) of the vane motor-driven downhole booster device is a drilling fluid inlet, which is connected with a drill collar or a power drilling tool. The sub-body (5) is installed on the inner step of the housing (1) near the inlet end of the device, and there are three holes on it, of which two symmetrical holes are connected with a pair of symmetrical vane motor fluid high-pressure inlets (4), and the other small hole The plunger pump (20) is supplied with inlet fluid through a line (9) connected to the one-way valve (10). The power source double-vane motor is located at the lower end of the split body (5), installed on the inner steps of the casing, and a gasket (11) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com