Partition type reverse jet regenerative diesel engine exhaust particulate filter device

A particle trap, diesel engine technology, applied in exhaust devices, mufflers, machines/engines, etc., can solve problems such as pollution, deterioration of the in-cylinder environment, and negative effects of diesel engine work, and achieve cost reduction, volume reduction, and lower cost. Demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

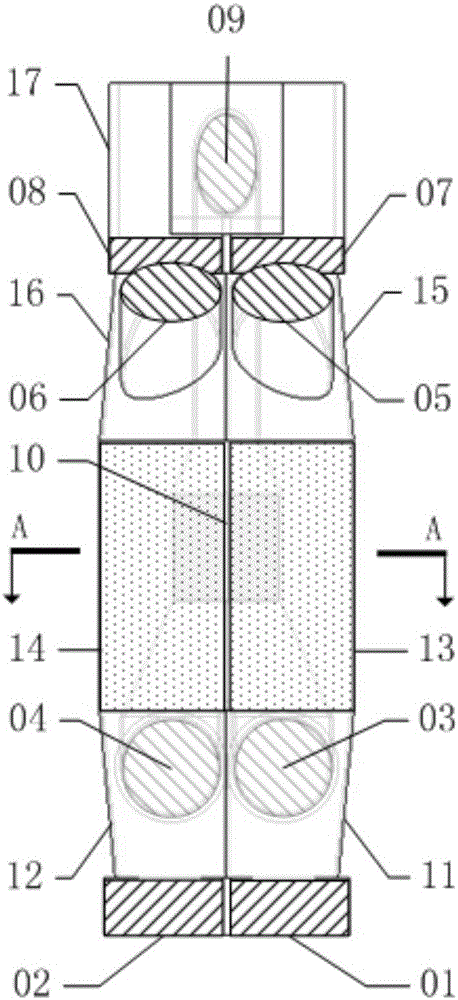

[0025] The present invention will be further described below in conjunction with accompanying drawing.

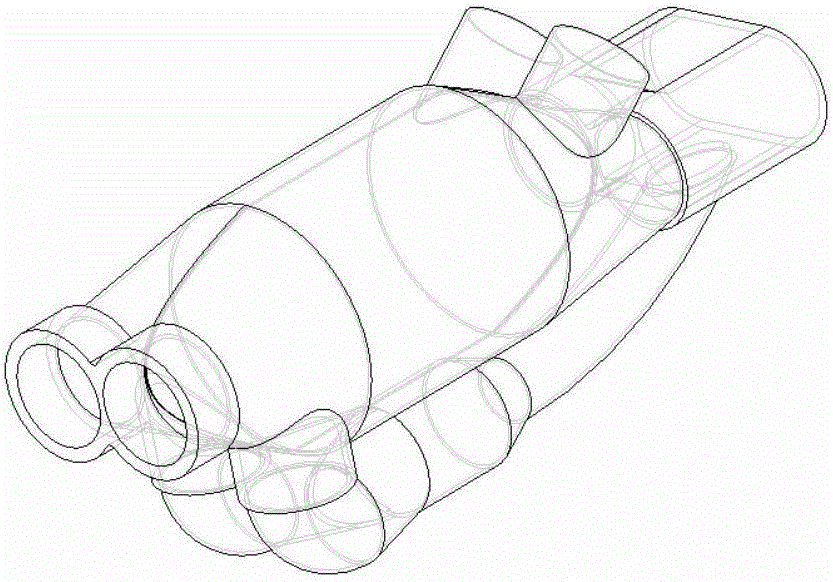

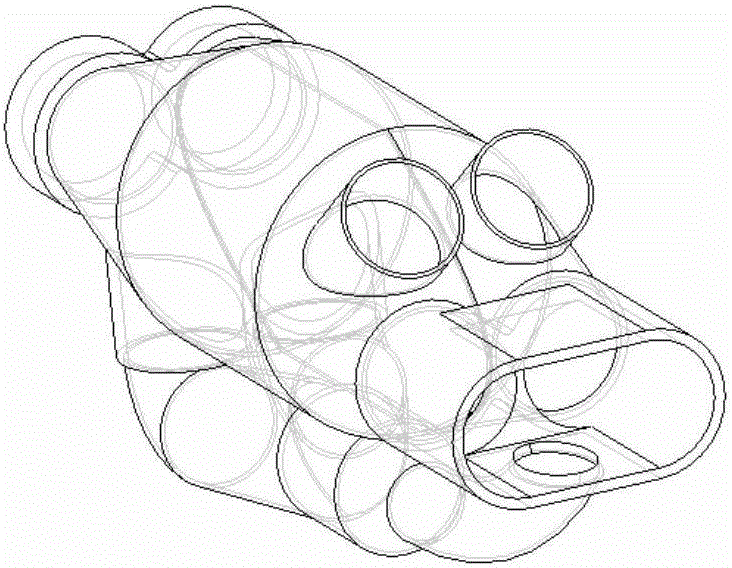

[0026] The invention relates to a separation type reverse jet regenerative diesel engine exhaust particle collector device. The front end of the device is connected to the exhaust outlet of the diesel engine through a pipeline, and the rear end is connected to other post-processing devices through the pipeline. The whole device consists of four parts: main filter system, regenerative filter system, jet system and control system.

[0027] The main filter system consists of two inlet valves, an inlet expansion tube, a main filter body, an outlet shrink tube, two air injection solenoid valves, two outlet valves and a main outlet tube. The inlet expansion tube of the main filter system, the main filter body and the outlet shrink tube are divided into two parts which are closed to each other. The main filter material is cordierite honeycomb ceramics, and the two parts of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com