Torsional vibration damper or rotationally elastic coupling

A technology for torsional vibration dampers and elastic couplings, applied in the direction of elastic couplings, shock absorber-spring combinations, couplings, etc., can solve the problem of reducing overflow grooves between cavities, affecting damping characteristics, reducing Problems such as complex assembly of vibrators or couplings, etc., achieve the effect of reducing costs and simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

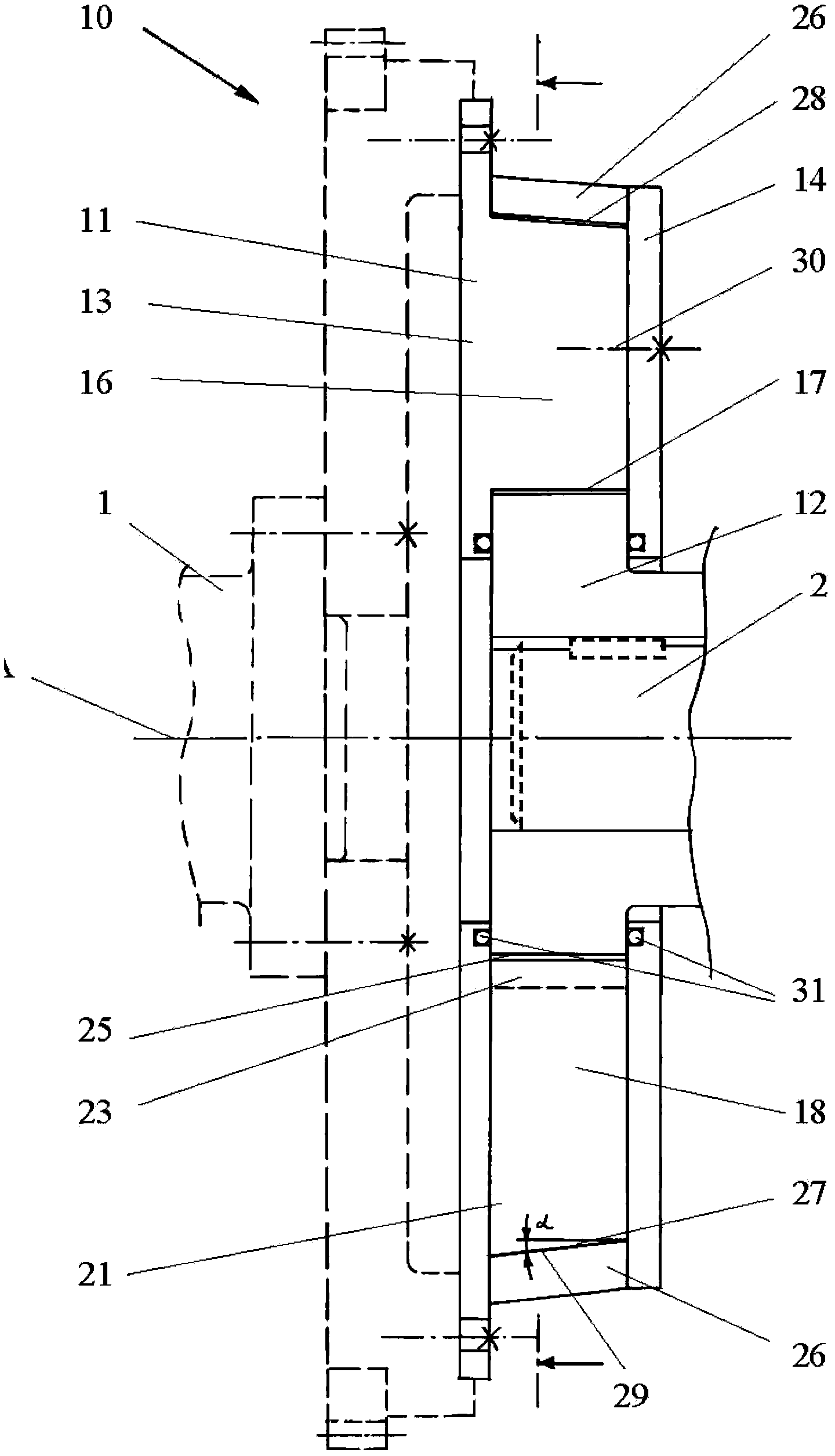

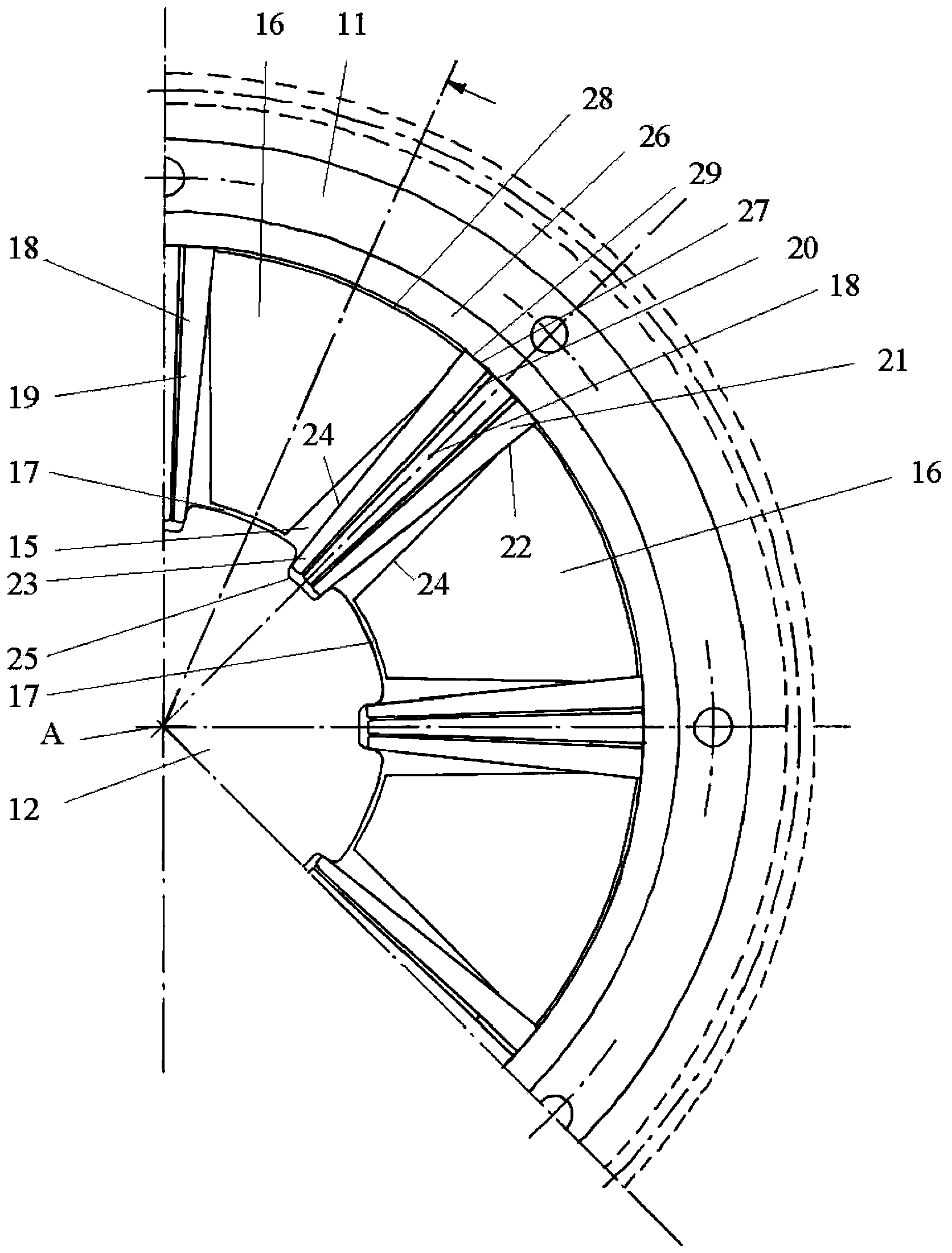

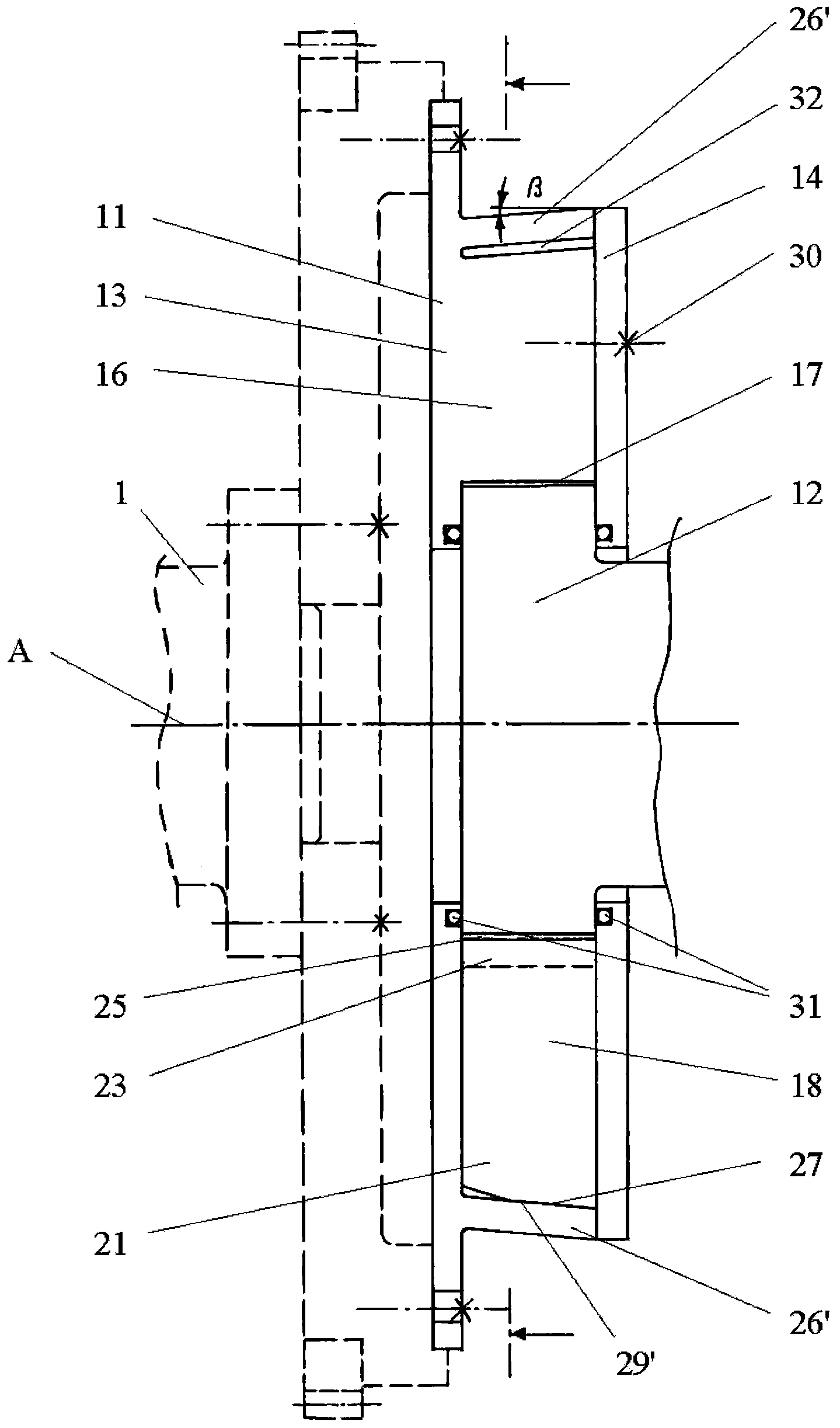

[0031] Such as figure 1 , 2 As shown, the rotating elastic coupling 10 is used to connect the first shaft 1 and the second shaft 2 and transmit torque between the first shaft 1 and the second shaft 2, and reduce vibration or change the torque during torque transmission .

[0032] The coupling 10 comprises a housing 11 , which is rotatable about a longitudinal axis A, and an inner part 12 which is arranged inside the housing 11 and which rotates about the longitudinal axis A relative to the housing 11 . The inner part 12 and the outer shell 11 are coaxial.

[0033] The housing 11 comprises a first flange 13 and a second flange 14 which are arranged facing each other and are sealed from the internal part 12 .

[0034] The shell 11 and the inner part 12 radially delimit a plurality of cavities 15, and the cavities 15 are filled with a damping medium, such as high-pressure oil. The cavities 15 are arranged sequentially along the circumferential direction of the inner part 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com