Multipurpose flat-plate-type solar device manufacturing method and corresponding multipurpose flat-plate-type solar device

A technology of solar energy device and manufacturing method, which is applied in the field of solar energy, can solve the problems of high cost, and achieve the effects of low cost, reduced use cost, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

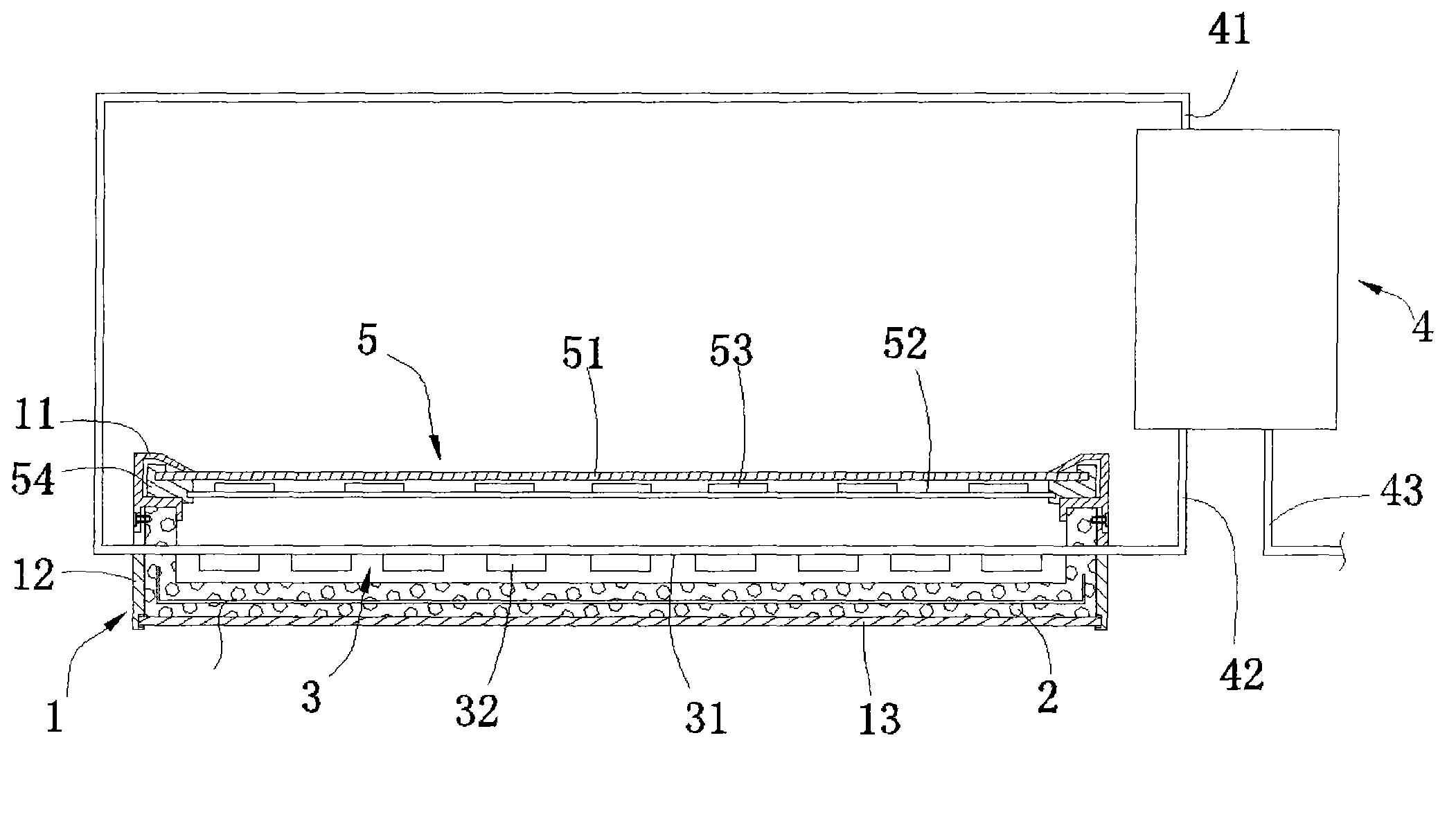

[0027] Example: see figure 1 , the embodiment of the present invention provides a multi-purpose flat solar device manufacturing method, which includes the following steps:

[0028] (1) Make a plate-shaped box body 1, and offer a light incident window on a side wall of the box body 1;

[0029] (2) A heat insulating layer 2 is provided on the inner side wall of the box body 1, and the heat insulating layer 2 is made of a ceramic composite material;

[0030] (3) Make heat collecting assembly 3, this heat collecting assembly 3 is arranged on the bottom of casing 1, this heat collecting assembly 3 comprises heat collecting coil 31 and some heat absorbing plates 32, the outer surface of heat absorbing plate 32 is coated with There is a heat-absorbing coating, and the heat-absorbing plate 32 is uniformly welded on the heat-collecting coil 31 by laser;

[0031] (4) Prepare ceramic material, make it into a container, form a ceramic hot water storage tank 4, a water inlet 41 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com