A gas pressure type optical fiber Bragg grating temperature sensor and its application method

A temperature sensor and gas pressure technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve problems such as use restrictions, achieve adjustable temperature measurement sensitivity, and achieve the effect of measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

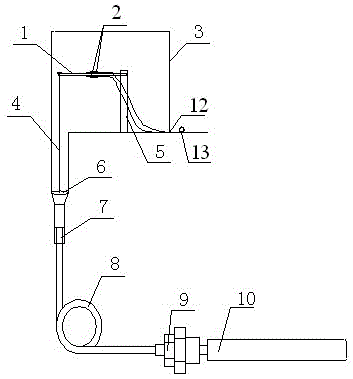

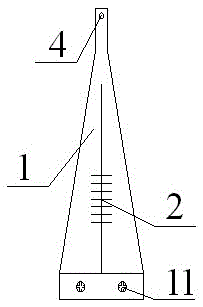

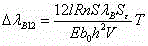

[0055] Implementation mode one: if figure 1 Shown, the structure of gas pressure type optical fiber Bragg grating temperature sensor of the present invention: comprise gas pressure temperature sensing device and optical fiber Bragg grating pressure conversion device, gas pressure temperature sensing device is connected capillary 8 and isolation tube 8 by sealed temperature change pressure sensing bag 10 Layer diaphragm 6; the main body of the optical fiber Bragg grating pressure conversion device is an equal-intensity cantilever beam 1 equipped with an optical fiber Bragg grating 2, and one end of the equal-intensity cantilever beam 1 transmits the pressure sensed by the gas pressure temperature sensing device through the interlayer diaphragm 6 ; The fiber Bragg grating 2 is connected to the external optical cable 13 to transmit the sensed signal. The equal-strength cantilever beam 1 is rigidly connected to the interlayer diaphragm 6 through the pressure transmission rod 4 , a...

Embodiment approach 2

[0069] Implementation mode two: if figure 1 Shown, the structure of gas pressure type optical fiber Bragg grating temperature sensor of the present invention: comprise gas pressure temperature sensing device and optical fiber Bragg grating pressure conversion device, gas pressure temperature sensing device is connected capillary 8 and isolation tube 8 by sealed temperature change pressure sensing bag 10 Layer diaphragm 6; the main body of the optical fiber Bragg grating pressure conversion device is an equal-intensity cantilever beam 1 equipped with an optical fiber Bragg grating 2, and one end of the equal-intensity cantilever beam 1 transmits the pressure sensed by the gas pressure temperature sensing device through the interlayer diaphragm 6 ; The fiber Bragg grating 2 is connected to the external optical cable 13 to transmit the sensed signal. The equal-strength cantilever beam 1 is rigidly connected to the interlayer diaphragm 6 through the pressure transmission rod 4 , a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com