Device for measuring heating mass loss rate of explosive powder

A mass loss rate, propellant and explosive technology, applied in the direction of weighing by removing certain components, can solve problems such as combustion and explosion, affecting the continuity of aging tests, etc., and achieve the effect of reducing weighing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

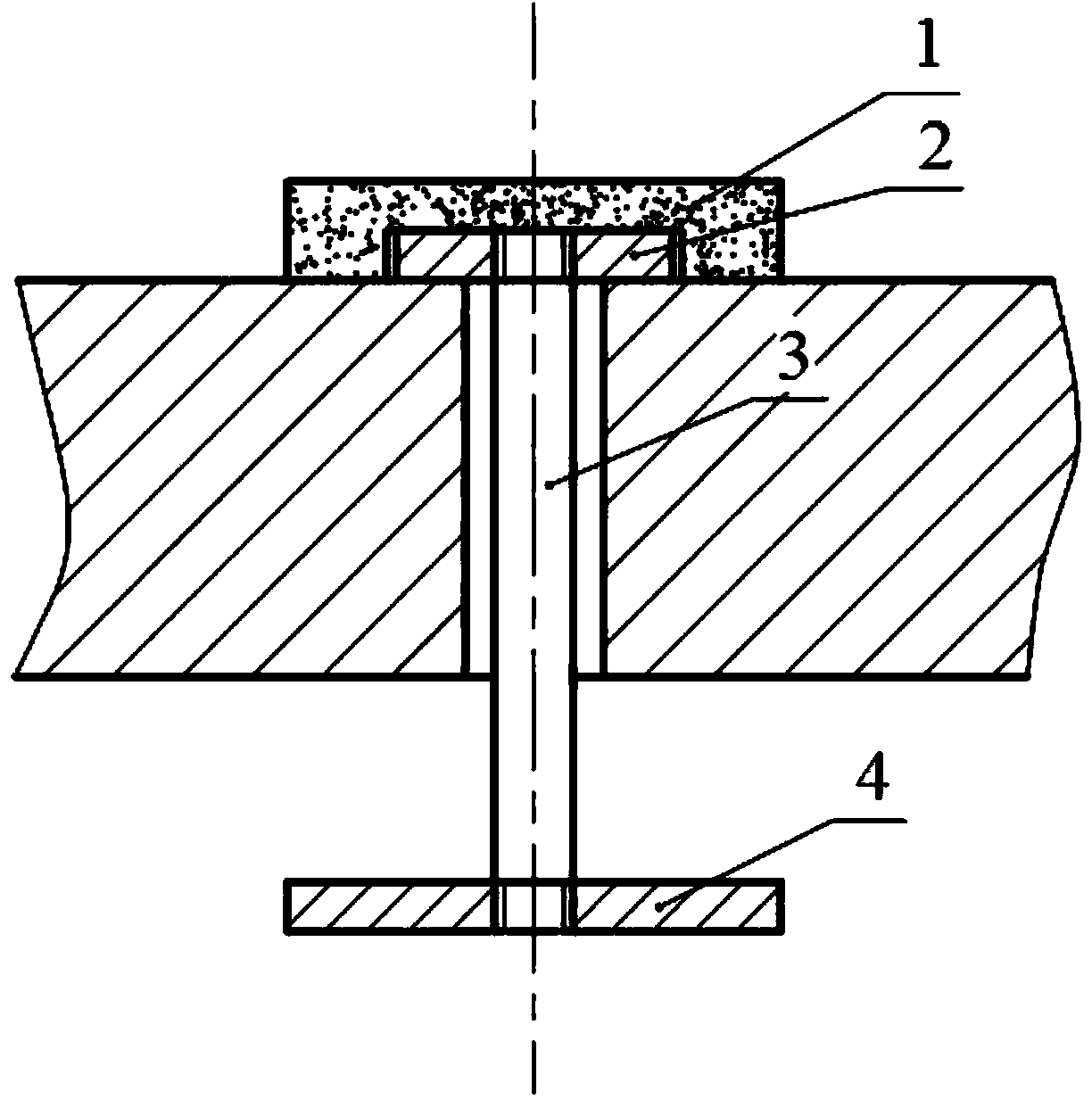

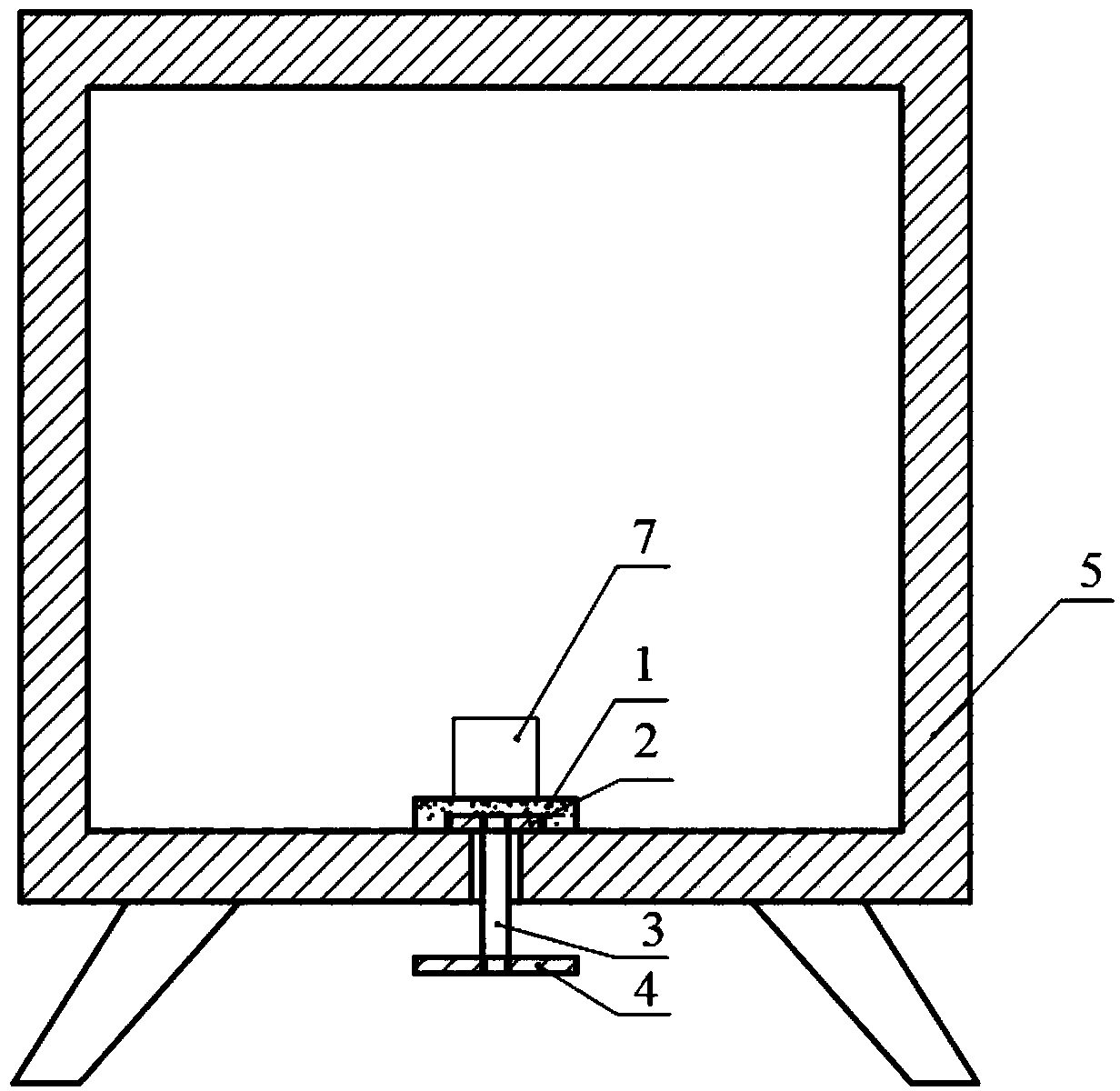

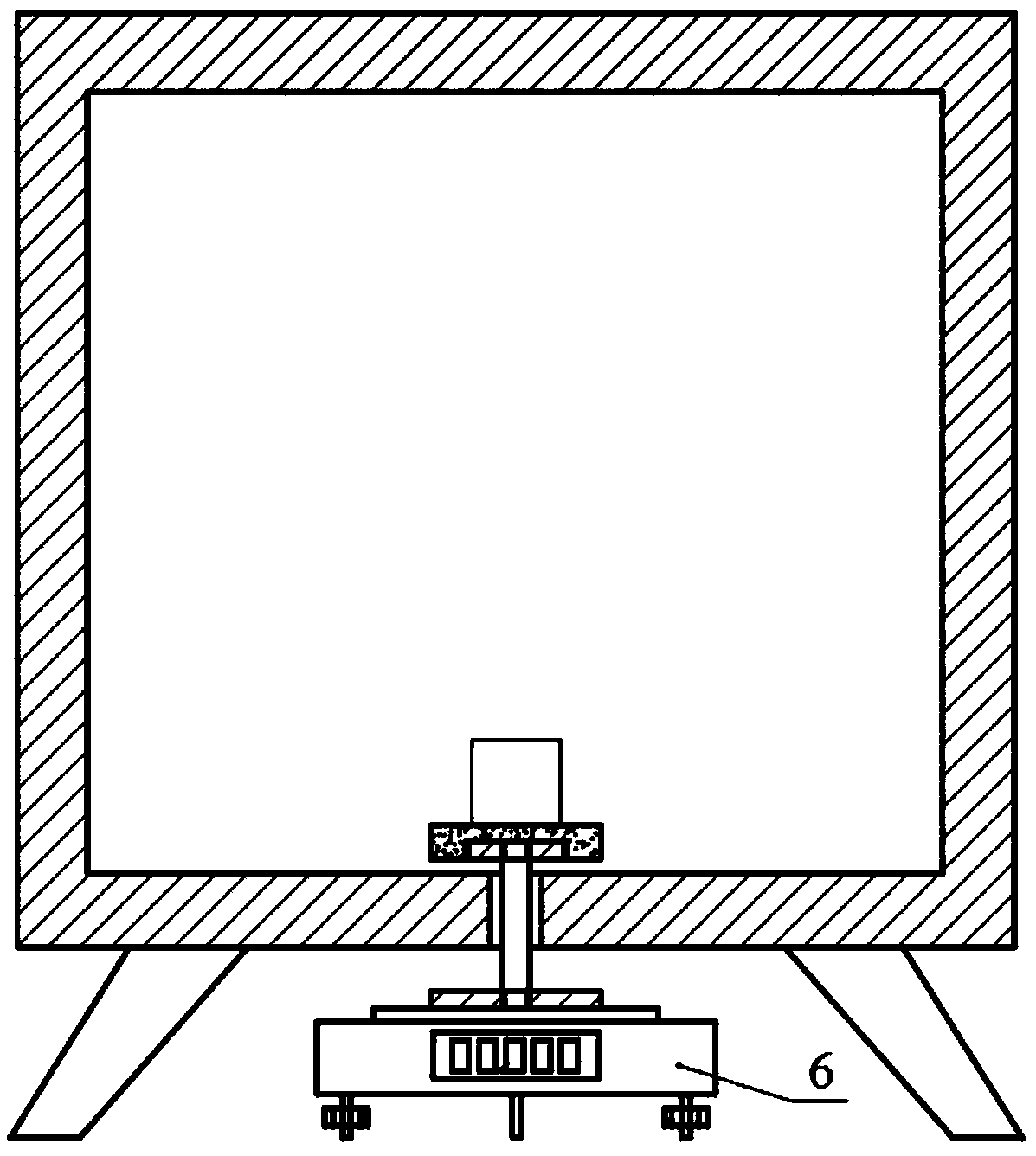

[0019] Referring to the accompanying drawings, the present embodiment provides a device for measuring the heating mass loss rate of explosives, including an oven 5, a through hole is provided at the bottom of the oven 5, a measuring bracket is installed in the through hole, and a tray balance is installed on the measuring bracket 6. The measuring support includes a heat insulating cover 1 , an upper disc 2 , a lower disc 4 and a support rod 3 . Wherein, the upper disc 2 is located inside the oven 5 , and the lower disc 4 is located outside the oven 5 .

[0020] The upper disc 2, the lower disc 4 and the support rod 3 are all made of aluminum. The upper disc 2 is a disc with a diameter of 28 mm and a thickness of 5 mm, with a threaded through hole of M8×0.5 in the center; the lower disc 4 is a disc with a diameter of 50 mm and a thickness of 5 mm, with a threaded through hole of M8×0.5 in the center; the support rod 3 is a rod shape with a length of 70 mm and a diameter of 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com