Laser module of point light source

A laser module and point light source technology, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of low roundness of point spot and point spot imaging, difficult processing and assembly, and complicated connection relationship, etc., to achieve Improve and ensure the roundness of the spot and the imaging quality of the spot, the effect of excellent visual effect and the roundness of the imaging spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

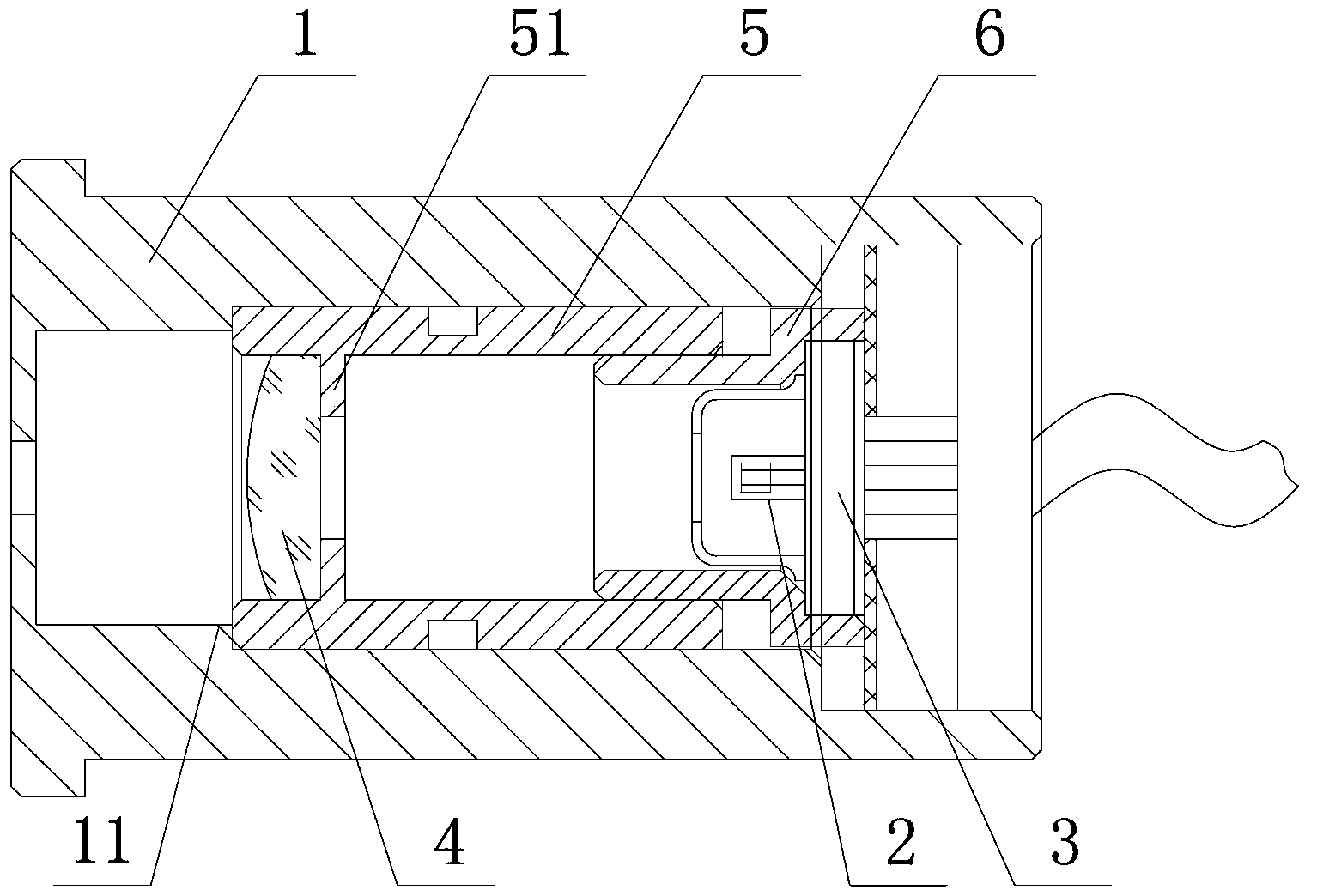

[0020] See figure 1 , the present invention includes a casing 1 and a laser diode 2 arranged in the casing 1, a driving circuit 3, a lens system 4, a lens barrel 5 and a laser diode positioning sleeve 6; the casing 1 is a metal casing, and the inner wall of the casing 1 is correspondingly provided with a limit position The step 11; the laser diode 2 is arranged at the rear end of the lens barrel 5, and the laser diode 2 is electrically connected with the drive circuit 3; the lens system 4 is arranged at the front end of the lens barrel 5; the lens system 4 is a single optical collimation lens. The lens barrel 5 is a metal lens barrel, and the inner wall of the lens barrel 5 has an annular limiting protrusion 51 ; the lens system 4 is fixedly glued on the annular limiting protrusion 51 . The laser diode positioning sleeve 6 is arranged between the laser diode 2 and the housing 1 .

[0021] The working principle of the present invention is: drive the laser diode 2 to work throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com