Data exchange device for steel rolling process control system and WinCC interface, and communication method thereof

A rolling process and control system technology, applied in transmission systems, electrical digital data processing, electrical components, etc., can solve problems such as poor user experience, cumbersome configuration, low technical reliability and security, and achieve reliability and efficiency High, simple and convenient operation, the effect of increasing the system burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

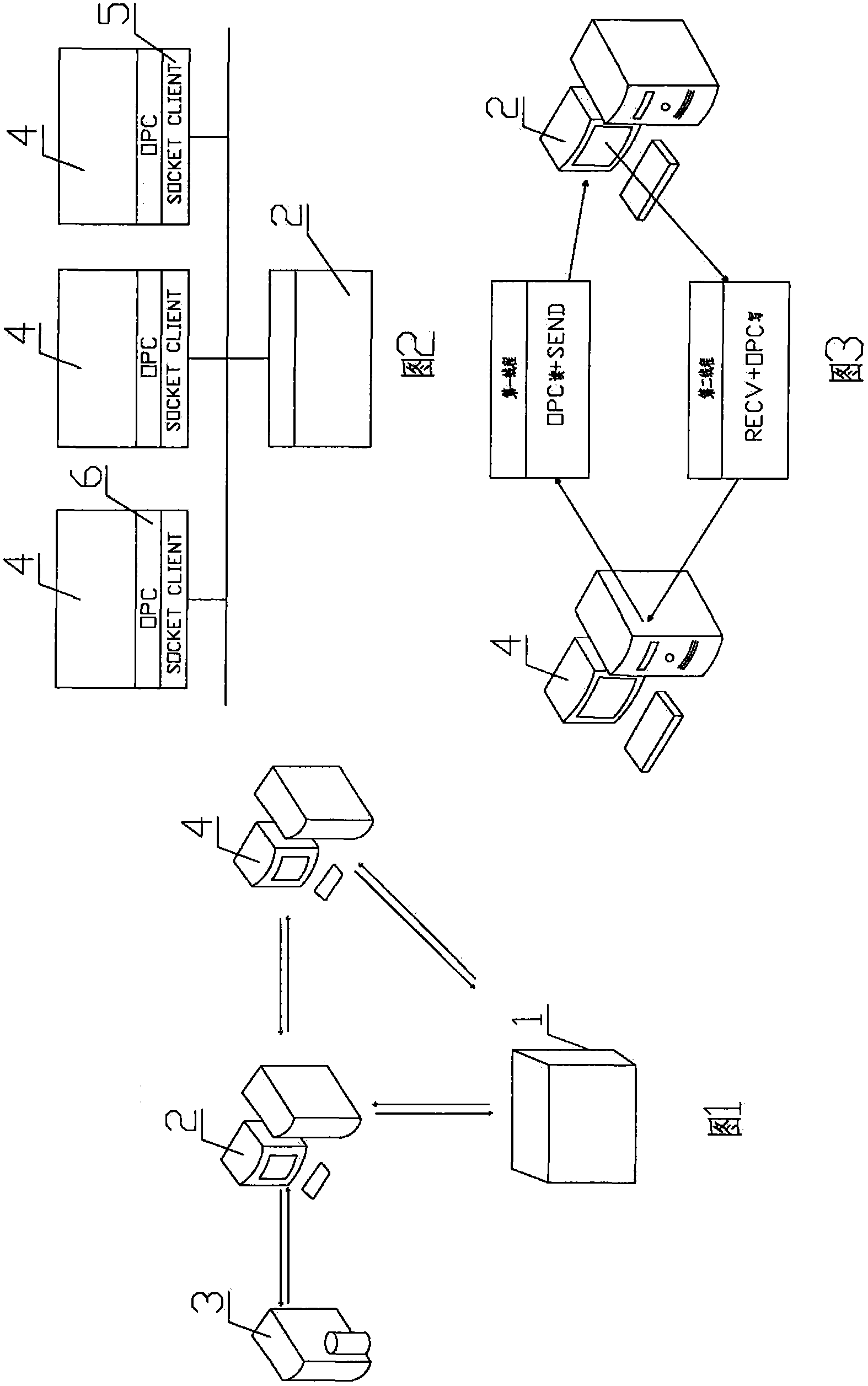

[0014] Embodiment 1: as Figure 1-2 As shown, a steel rolling process control system and WinCC interface data exchange device, including PLC1, process machine 2 using SOCKET communication mechanism, database machine 3 and at least two HMI4, the initial parameter output terminal of database machine 3 through The wire is electrically connected to the initial parameter input end of the process machine 2, and the first model setting data output end of the process machine 2 is electrically connected to the model setting data input end of the database machine 3 through the wire, and is used on the HMI4 The outer layer interface 5 for data exchange between SOCKET and process machine 2 and the inner layer interface 6 for reading and writing data in WinCC software in accordance with OPC technical specifications. The second model setting data output end of process machine 2 communicates with the outer layer of HMI4 through wires The second model setting data input end of the interface 5...

Embodiment 2

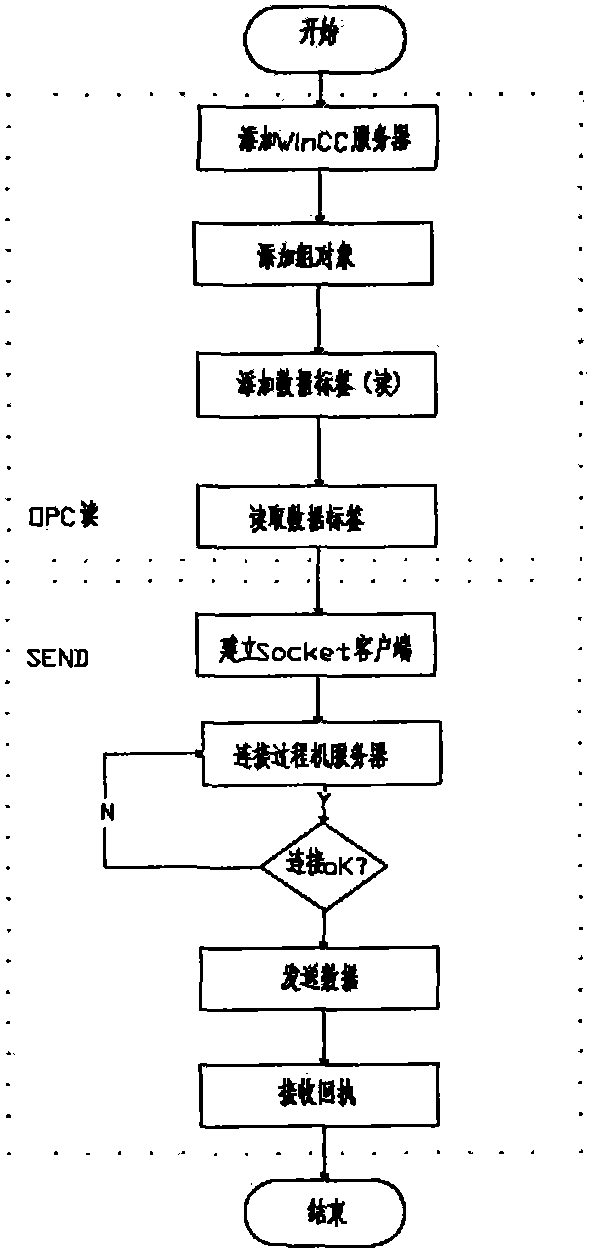

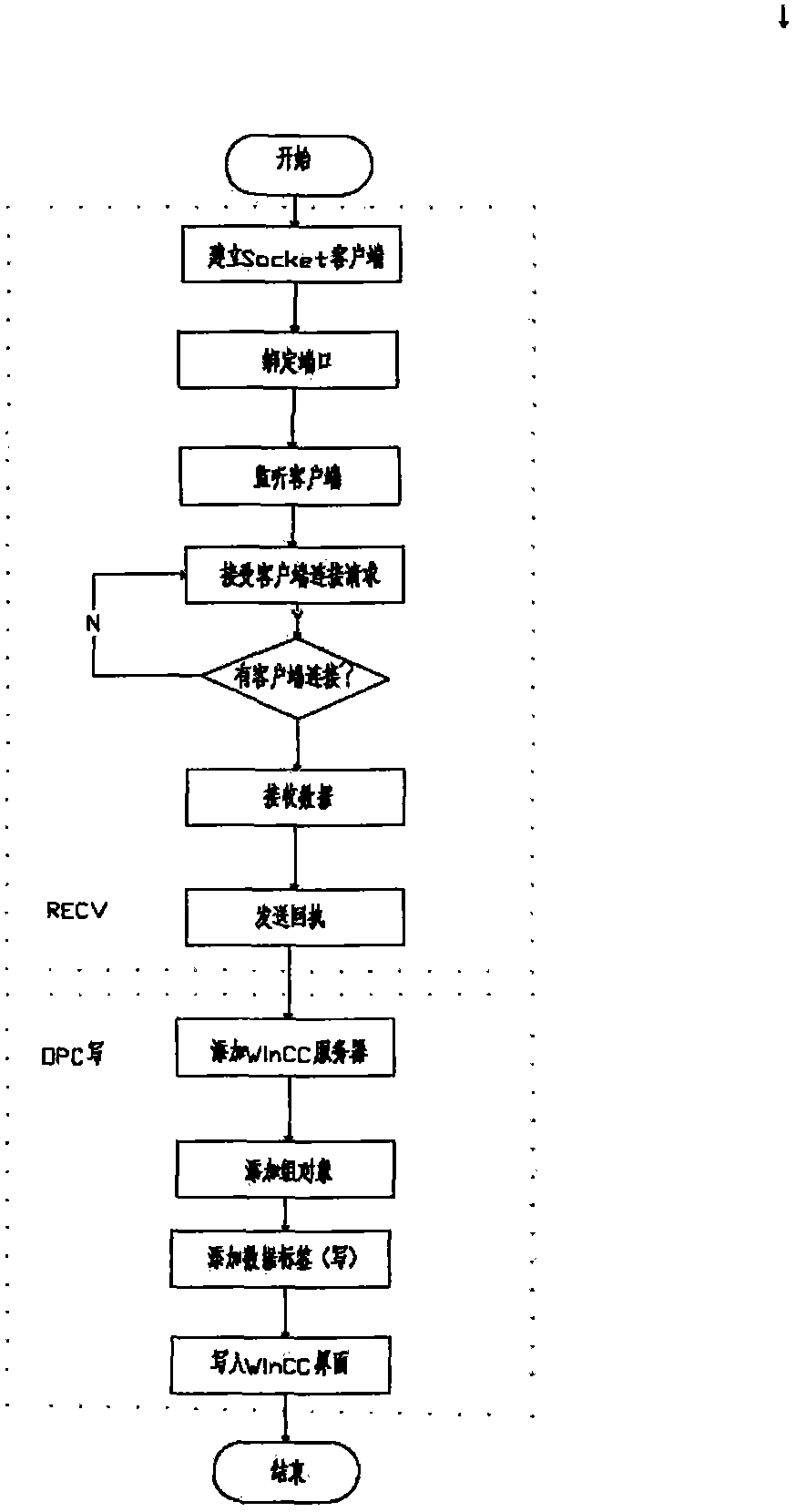

[0015] Embodiment 2: a kind of communication method using steel rolling process control system and WinCC interface data exchange device: its thread is the first thread that process machine 2 sends to HMI4 and the second thread that HMI4 sends to process machine 2; The flow of the thread is: first add the WinCC server at the beginning, then add the OPC group object, then add the data tag, then read the data tag, then establish a SOCKET client, then connect to the process machine server, send data when connected, and then receive the receipt After completion, reconnect when not connected to the process machine server; the process of the second thread is to first establish a SOCKET client, then bind the port, then monitor the client, and then accept the client connection request. When there is a client connection, After receiving the data, send a receipt, then add the WinCC server, then add the OPC group object, then add the data label, and then write to the WinCC interface to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com