Thyratron Inflation System

A technology of gas filling system and thyratron, which is applied in the direction of electric tube/lamp filling, etc., can solve the problems of high cost, high price, and increased pressure difference of palladium alloy tubes, and achieve large gas storage capacity, high gas purity, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

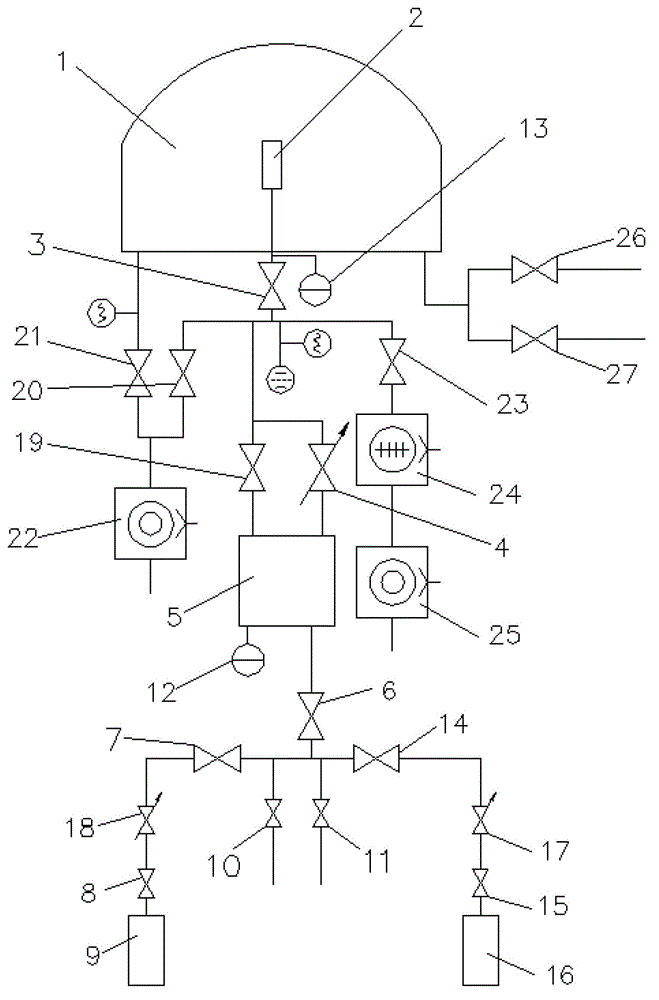

[0031] like figure 1 As shown, a thyratron inflation system includes a thyratron 2 placed in a sealed cavity 1 formed by a metal oven (where one or more thyratrons can be set according to the sealed cavity, and each thyristor tube needs to be provided with a position valve for control), the thyratron is connected to a hydrogen storage tank 5 through a pipeline, and a position valve 3 and a hydrogen charging tank are sequentially arranged on the pipeline between the thyratron and the hydrogen storage tank The fine-tuning valve 4; the hydrogen storage tank 5 is connected to a first metal h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com