Method of making a thin film transistor device

A technology of thin film transistors and manufacturing methods, applied in the field of thin film transistors, can solve problems such as increased manufacturing costs, large screen size, and prolonged manufacturing time, and achieve the effects of simplifying manufacturing complexity, shortening manufacturing process time, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

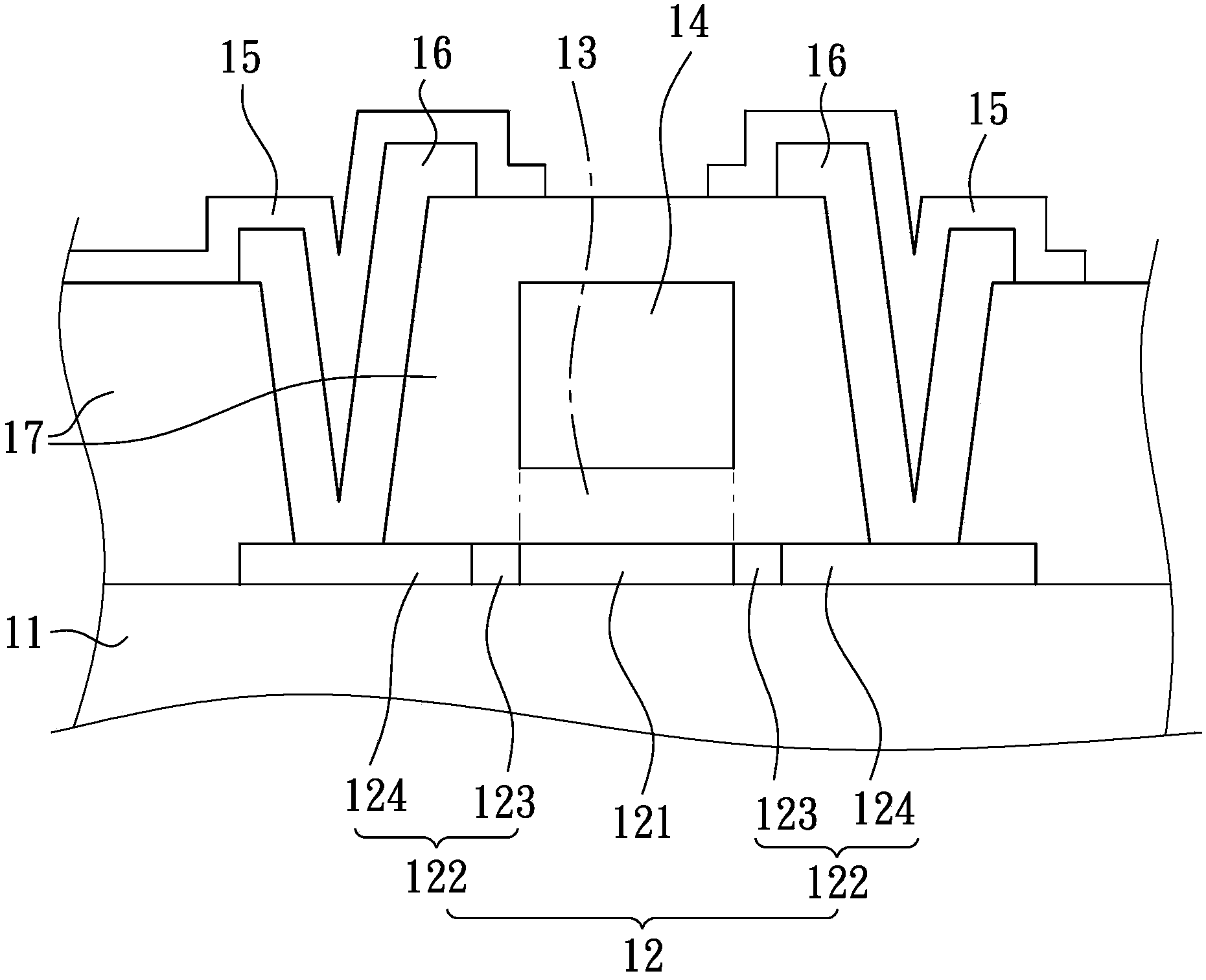

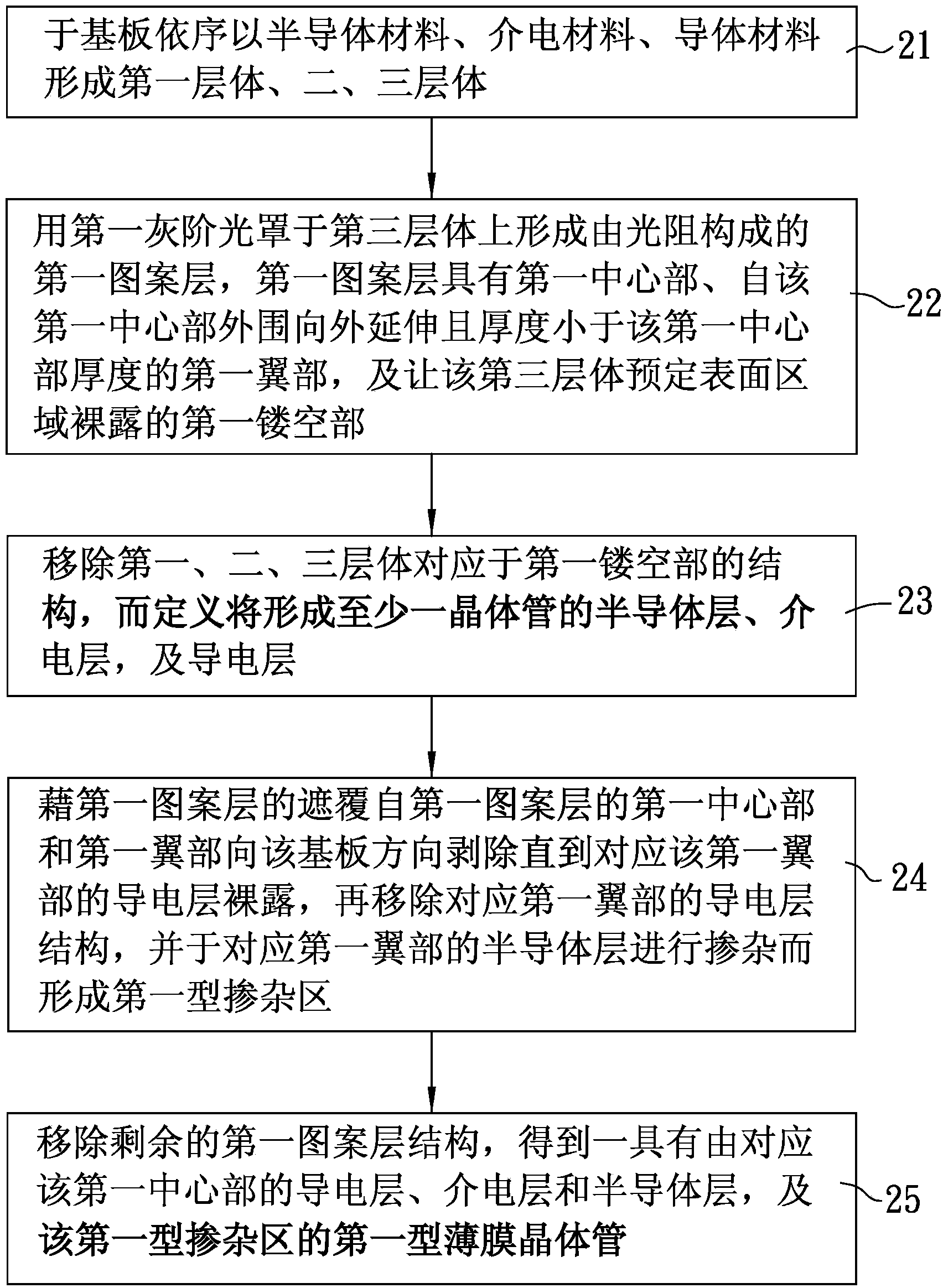

[0059] refer to figure 2 , a first preferred embodiment of the method for fabricating a thin film transistor of the present invention produces at least one first type thin film transistor, and in the following description, the first type thin film transistor is produced to produce such figure 1 The n-type thin film transistor shown is an example, but not limited to n-type thin film transistors, and may also be p-type thin film transistors. The manufacturing method of the n-type thin film transistor includes a step 21 , a step 22 , a step 23 , a step 24 and a step 25 .

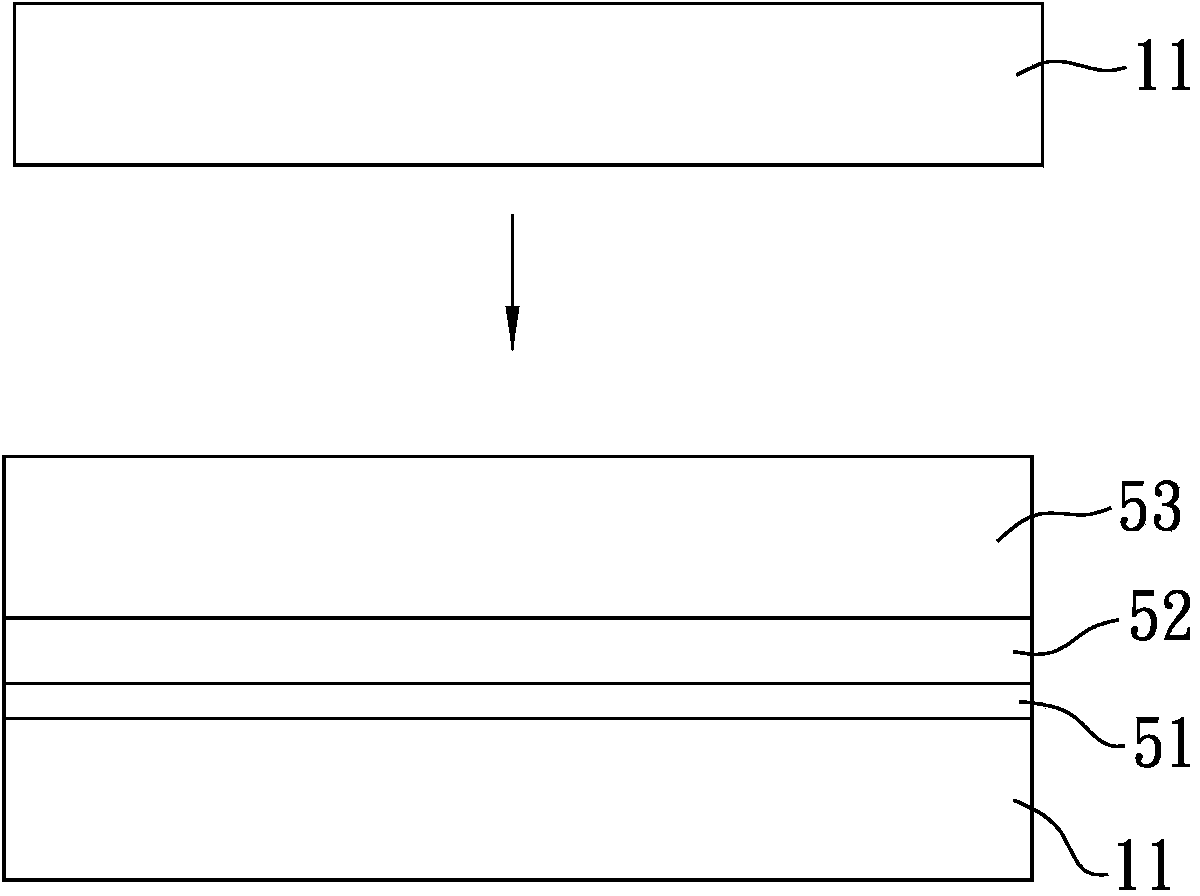

[0060] Firstly, the step 21 is performed to form a first layer, a second layer, and a third layer on a substrate sequentially using semiconductor material, dielectric material, and conductive material. Continue, proceed to step 22, use a first gray scale photomask to form a first pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com