Lithium battery pole plate

A lithium battery and electrode technology, applied in the field of material science, can solve the problems of poor electrode conductivity, harsh reaction conditions, and complicated reaction process, and achieve the effects of large specific surface area, low cost, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

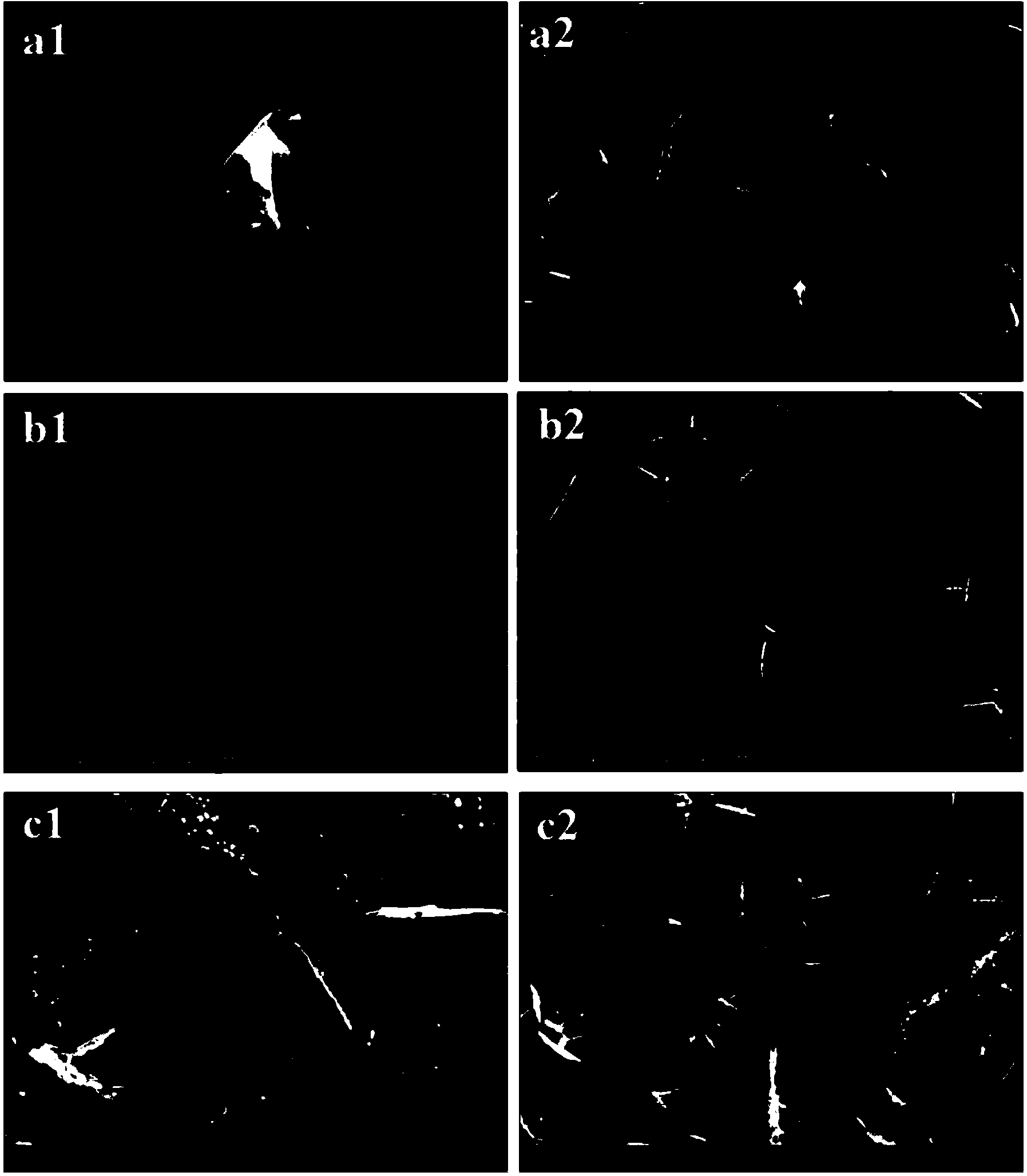

[0035] The influence of embodiment 1 different silver nitrate concentrations on current collector

[0036] (1) Use water as a solvent to prepare a silver nitrate solution;

[0037] (2) Ultrasonic wash the copper sheet several times with deionized water and ethanol, and then let the copper sheet dry naturally;

[0038] (3) By the chemical bath method, immerse the copper sheet in the silver nitrate solution for a certain period of time, and then wash it several times with deionized water and ethanol.

[0039] Reaction conditions are as shown in table 1:

[0040] Table 1

[0041]

[0042] The result is as figure 1 As shown, when the concentration of silver nitrate was 2mM, sheet-like silver grew on the surface of the copper sheet, and the silver nanosheets were thinner. With the increase of the concentration of silver nitrate, the thickness of the silver nanosheets increased. When the concentration increased to 6mM, Obvious granular silver appeared on the surface of silver...

Embodiment 2

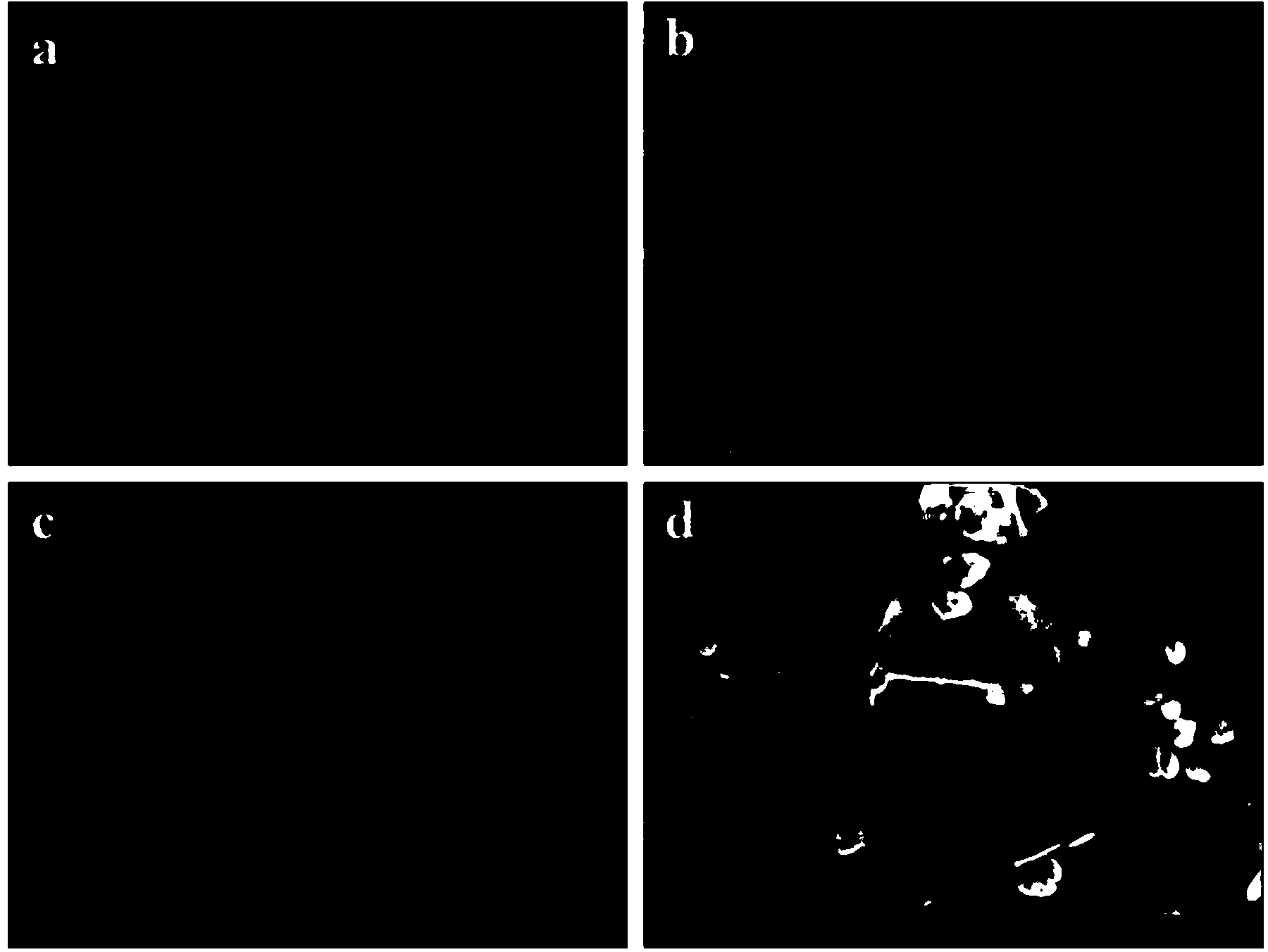

[0043] The influence of embodiment 2 different reaction times on current collector

[0044] The method is the same as in Example 1, and the reaction conditions are as shown in Table 2.

[0045] Table 2

[0046]

[0047] The result is as figure 2 As shown, when the concentration of silver nitrate is 4mM, as the reaction time increases, the silver nanosheets grown on the surface of the copper sheet increase and thicken. When the reaction is 60s, the surface of the silver nanosheets appears obvious granular silver.

Embodiment 3

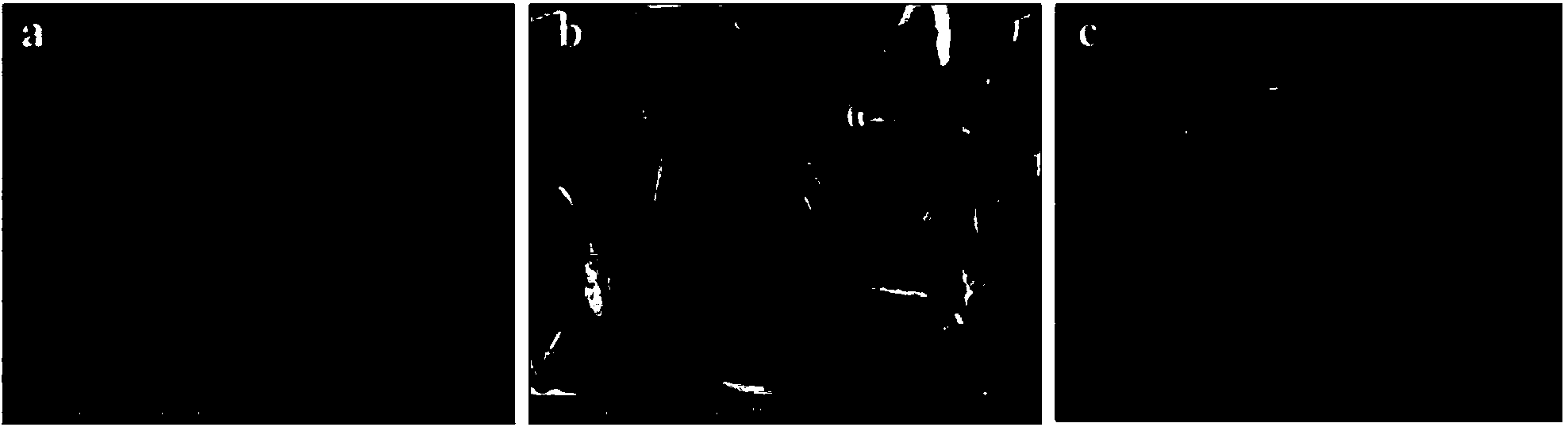

[0048] The influence of embodiment 3 different reaction temperatures on current collector

[0049] The method is the same as in Example 1, and the reaction conditions are as shown in Table 3.

[0050] table 3

[0051]

[0052] Such as image 3 As shown, when the reaction temperature is high, the silver grown on the copper surface is granular, and as the reaction temperature gradually decreases, the silver grown on the copper surface gradually transitions to flakes, and when the temperature reaches a certain level, the silver grown on the copper surface is flaky.

[0053] To sum up, the concentration of silver nitrate, reaction time, and reaction temperature all have an impact on the morphology and structure of silver grown on the copper surface, among which the reaction temperature has the greatest impact.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com