A kind of anti-leakage floor heating plate and its manufacturing method

A manufacturing method and anti-leakage technology, applied in the direction of heating methods, electrical components, electric heating systems, etc., can solve the problems of large leakage current, many safety hazards, and failure to close the gate, etc., to solve safety hazards, simple structure, and reduce leakage The effect of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

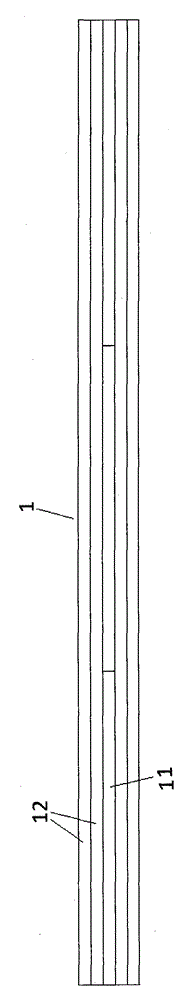

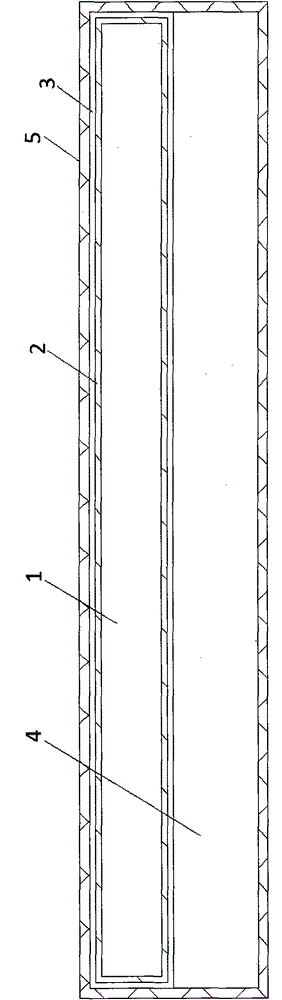

[0023] refer to Figure 1-3 , the leakage-proof floor heating board includes a carbon crystal heating board 1, a polyester film 2, an insulating film 3, a thermal insulation board 4 and a shrink film 5; the carbon crystal heating board 1 is plastic-sealed in the polyester film 2 to form a heating board, and and the polyurethane insulation board 4 are plastic-sealed in the shrink film 5;

[0024] Among them, the carbon crystal heating board 1 includes three conductive ink substrates 11 and glass fiber epoxy resin boards 12, two layers of glass fiber epoxy resin boards 12 are arranged on both sides of the conductive ink substrate 11; layer, the insulation layer material is polyurethane, and the reflective layer material is aluminum plate.

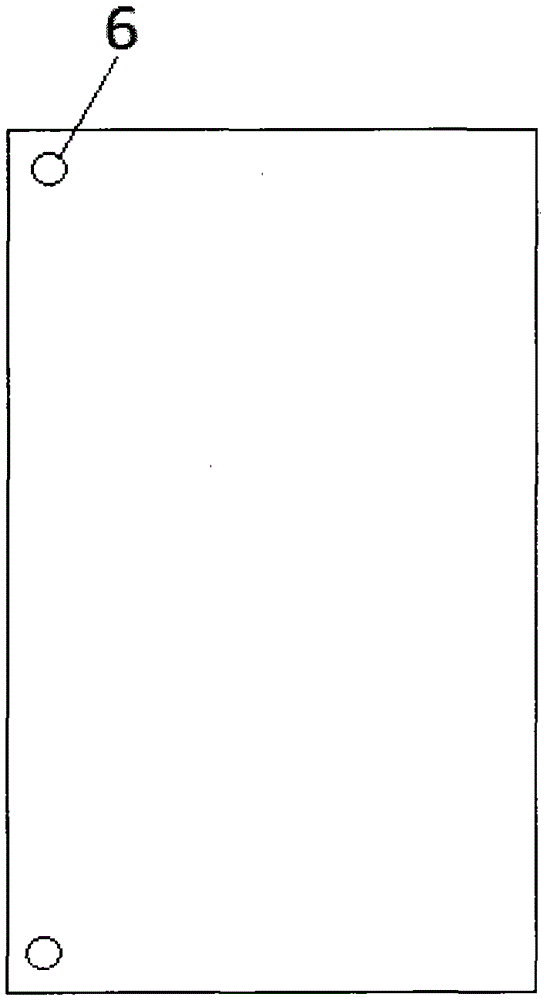

[0025] Preferably, the homopolar conductive terminals of the three conductive ink substrates 11 in the heating plate are connected by a copper foil plate, and the heating plate is provided with a hole 6 for connecting wires corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com