Ultra-wide band electromagnetic band-gap structure

A technology of electromagnetic bandgap structure and electromagnetic bandgap unit, which is applied in the direction of printed circuit components, etc., can solve problems such as high-frequency synchronous switching noise, etc., and achieve the effect of easy implementation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

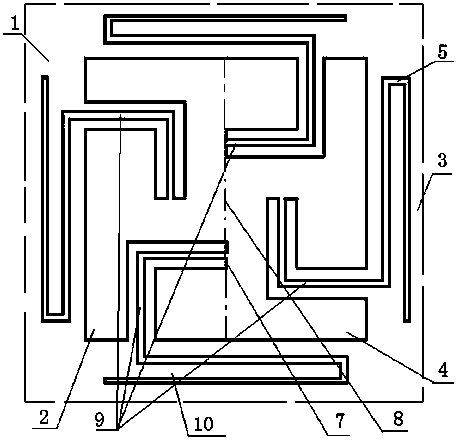

[0022] like figure 1 As shown, an ultra-broadband electromagnetic bandgap structure at least includes a non-conductive substrate 1, the non-conductive substrate 1 is covered with a metal plate 2, and the metal plate 2 is corroded into electromagnetic bandgap units 3 distributed at intervals; Two tape gap units 3 are arranged side by side.

Embodiment 2

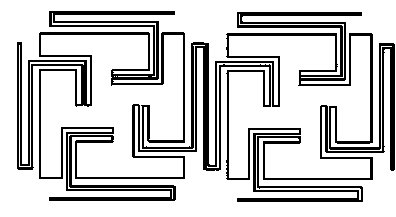

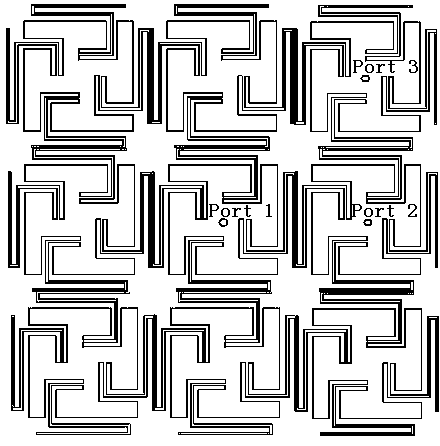

[0024] like figure 2 As shown, an ultra-broadband electromagnetic bandgap structure at least includes a non-conductive substrate 1, the non-conductive substrate 1 is covered with a metal plate 2, and the metal plate 2 is corroded into electromagnetic bandgap units 3 distributed at intervals; There are nine tape gap units 3, and the nine are distributed into a 3*3 square.

[0025] like image 3 As shown, the electromagnetic bandgap unit 3 is composed of a square body 4 on one side of the non-conductive substrate 1, conductor lines 5 extending outward on the four sides of the square body, and an L-bridged EBG structural unit 6 on the other side, and the four sides are outwardly The extended conductor line 5 is perpendicular to the four sides of the square body 4, and the four sides extend outward. The conductor line 5 extends outward from the 1 / 3-1 / 4 position of the connecting side, and the starting point 7 is close to the vertical center line 8 of the square body, The non-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com