Condensed tannin-containing composition which is cured by application of heat and pressure

A composition and condensation-type technology, which is applied in the field of manufacturing shaped bodies, can solve the problems such as the inability to use the main components of non-fossil resource-derived materials, and achieve the effects of simple manufacturing process, high widely usability, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

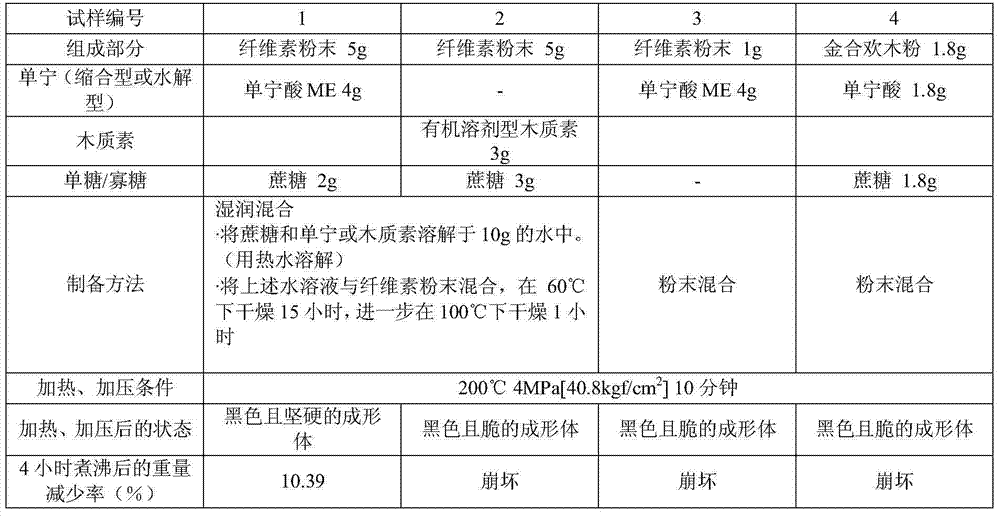

[0076] [Example 1] Curing experiment

[0077] Using cellulose filter paper powder (consisting almost 100% of cellulose) as a component, prepared vitex tannin (in the table, denoted as tannic acid ME) as a condensed tannin, and oligosaccharide (sucrose) Composition (Sample 1). In addition, a composition was prepared by adding lignin and sucrose without adding condensed tannin to the cellulose filter paper powder (sample 2). In addition, a composition (sample 3) in which only condensed tannins were added to the cellulose filter paper powder was prepared. Furthermore, a composition (sample 4) in which hydrolyzable tannin (gala tannin) and sucrose were added to acacia wood powder (which hardly contained condensed tannin) was prepared.

[0078] These compositions were heated and pressurized under the conditions shown in Table 1 to form molded bodies, and water resistance was evaluated. The results are shown in Table 1.

[0079] [Table 1]

[0080]

[0081] As shown in Table ...

Embodiment 2

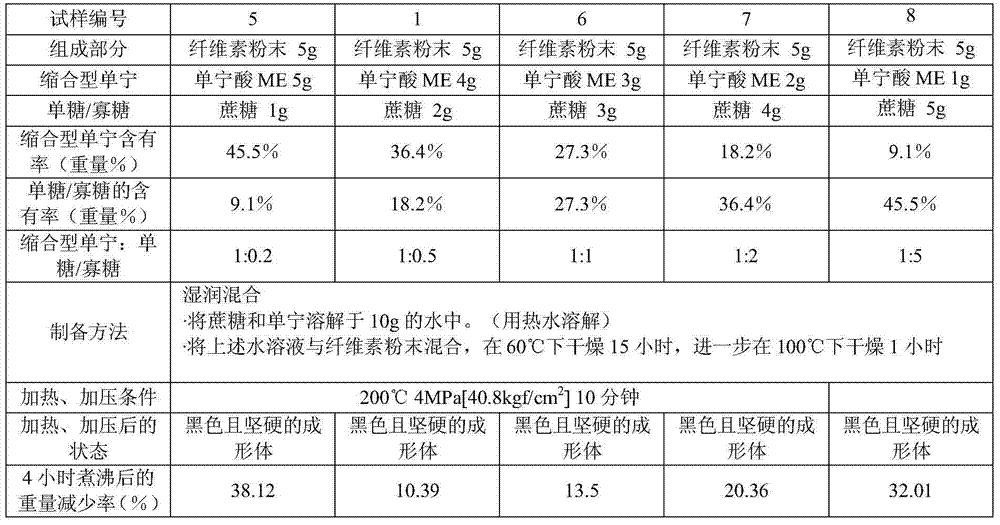

[0083] [Example 2] Research on the weight ratio of condensed tannins and monosaccharides / oligosaccharides

[0084] Using cellulose filter paper powder, wattle tannin, and sucrose, various compositions having different mixing ratios were prepared, molded products were produced under the conditions shown in Table 2, and water resistance was evaluated. The results are shown in Table 2. The ratios of condensed tannins and sucrose reported in the tables are weight ratios.

[0085] [Table 2]

[0086]

[0087] As shown in Table 2, all compositions in which the weight ratio of sucrose to condensed tannin 1.0 was in the range of 0.2 to 5.0 were cured by heating and pressing to obtain plastic-like molded articles. In particular, a composition having a weight ratio of condensed tannin 1.0:sucrose 0.5 to 1.0 is excellent in water resistance.

Embodiment 3

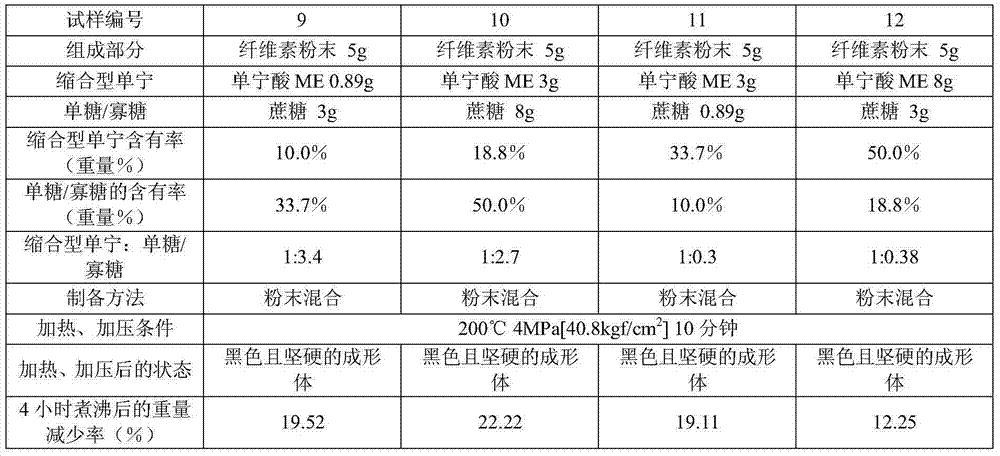

[0088] [Example 3] Study on the content rate of condensed tannins and monosaccharides / oligosaccharides

[0089] Using cellulose filter paper powder, wattle tannin, and sucrose, the composition was prepared in such a way that the content of wattle tannin or sucrose reached 10% by weight or 50% by weight, and hot pressing was carried out under the conditions shown in Table 3, Water resistance was evaluated. The results are shown in Table 3.

[0090] [table 3]

[0091] Table 3 Research on the content rate of condensed tannins and monosaccharides / oligosaccharides

[0092]

[0093] As shown in Table 3, all the compositions were cured by heating and pressing to become plastic-like molded objects. In addition, the weight reduction rates after the boiling treatment were all 25% or less. From this, it can be seen that even if the content of wattle tannin or sucrose is varied between 10% and 50% by weight, a plastic-like molded article can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com