Device and method for automatically picking pineapples

An automatic picking and pineapple technology, applied in applications, agricultural machinery and implements, harvesters, etc., can solve problems such as inability to effectively reduce equipment costs, high positioning requirements for manipulators, and low picking efficiency, to save picking costs and work reliably. Simple, Efficient Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

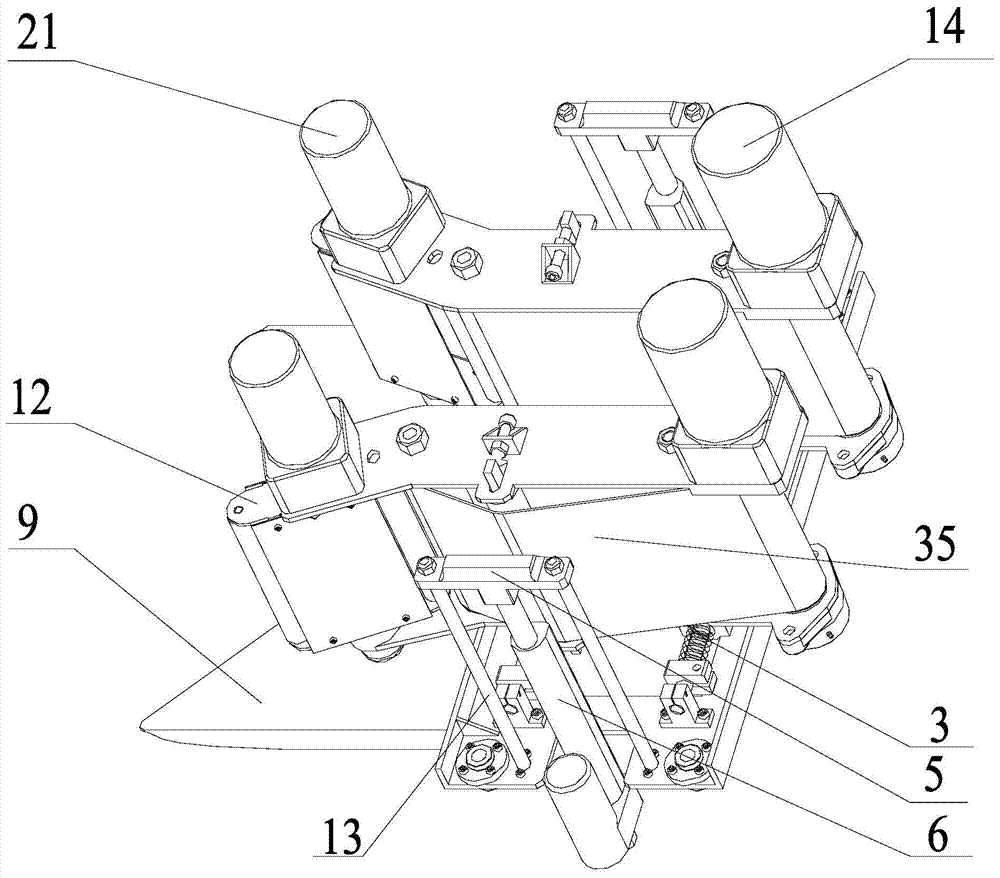

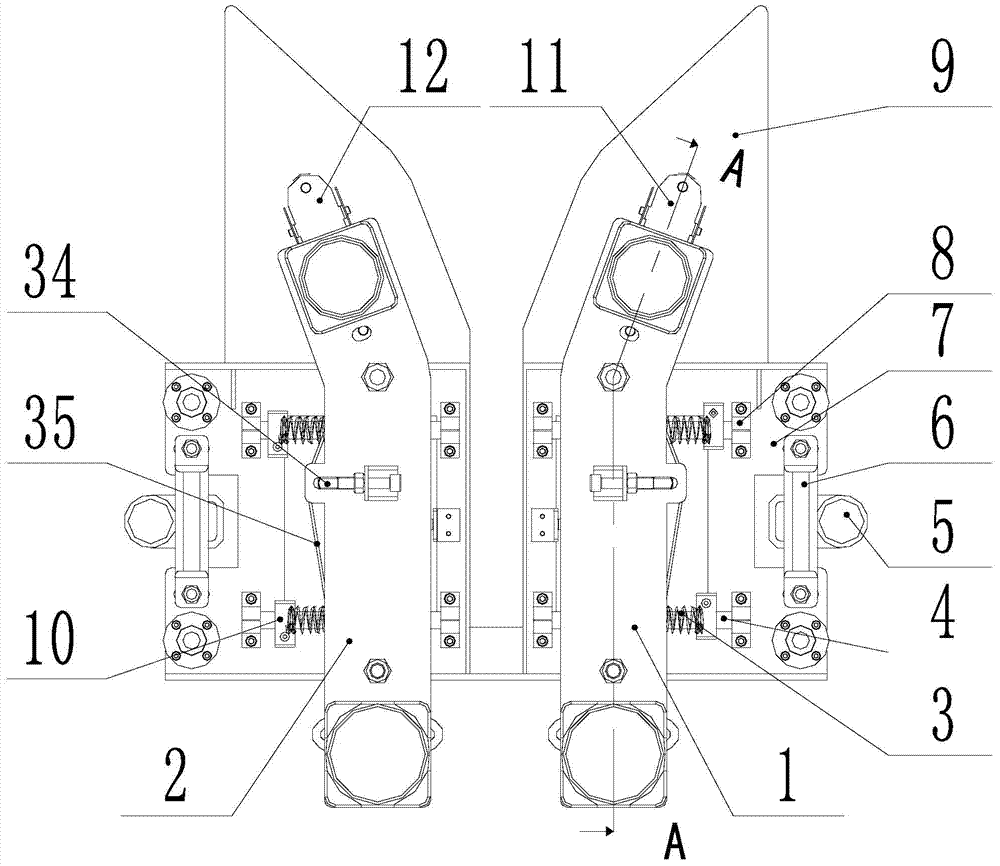

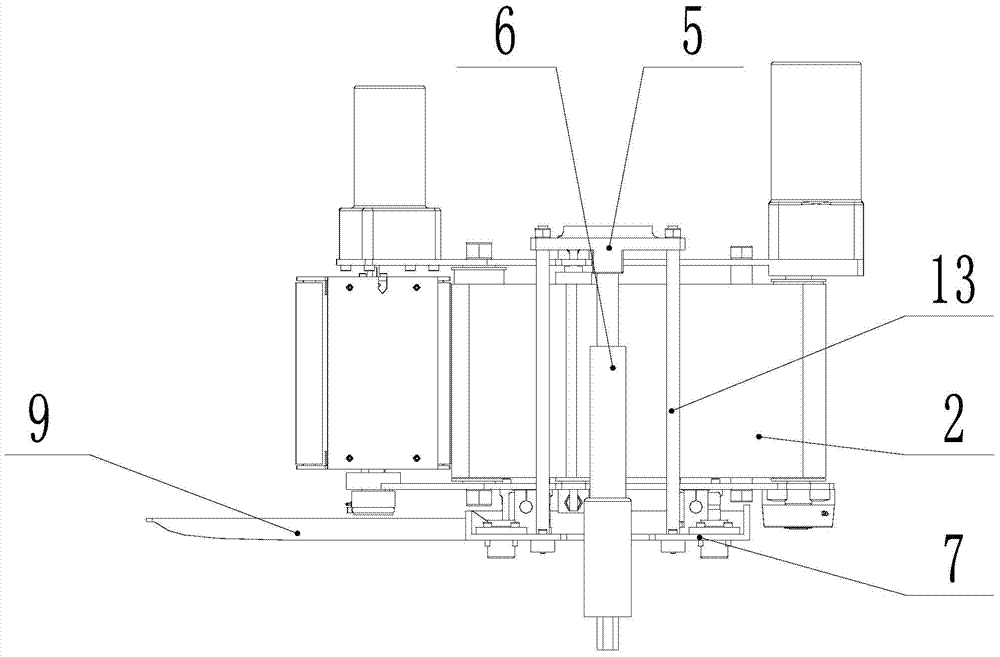

[0042] Such as Figure 1~5 As shown, a device for automatically picking pineapples includes a transverse guide mechanism, a forwarding correction posture mechanism, a twist-off harvesting mechanism, and a picking platform mechanism that connects the above-mentioned mechanisms.

[0043] The lateral guide mechanism in this embodiment includes a left-right symmetrical guide plate 9, the rear end faces of the two plates are fixedly connected with the front plane of the picking platform 7 with bolts, the guide plate is a V-shaped plate, and the two guide plates form a "V" Type guide groove. The working principle of the lateral guide mechanism: when the device in this embodiment moves forward, the pineapple fruits that are planted in rows but have different lateral positions pass through the "V"-shaped guide grooves formed by the symmetrically arranged guide plates 9 to the fruit stems. The pineapple fruit is guided and positioned to advance the middle position of the posture corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com