A gas-liquid guiding tray

A tray, gas-liquid technology, applied in the field of gas-liquid mass transfer equipment in chemical separation process, can solve the problems of inappropriate liquid seal height of downcomer, uneven liquid velocity distribution, affecting the normal flow of liquid phase, etc. The effect of increasing the liquid mass transfer area, uniform distribution of gas and liquid phases, and increasing the gas-liquid mass transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

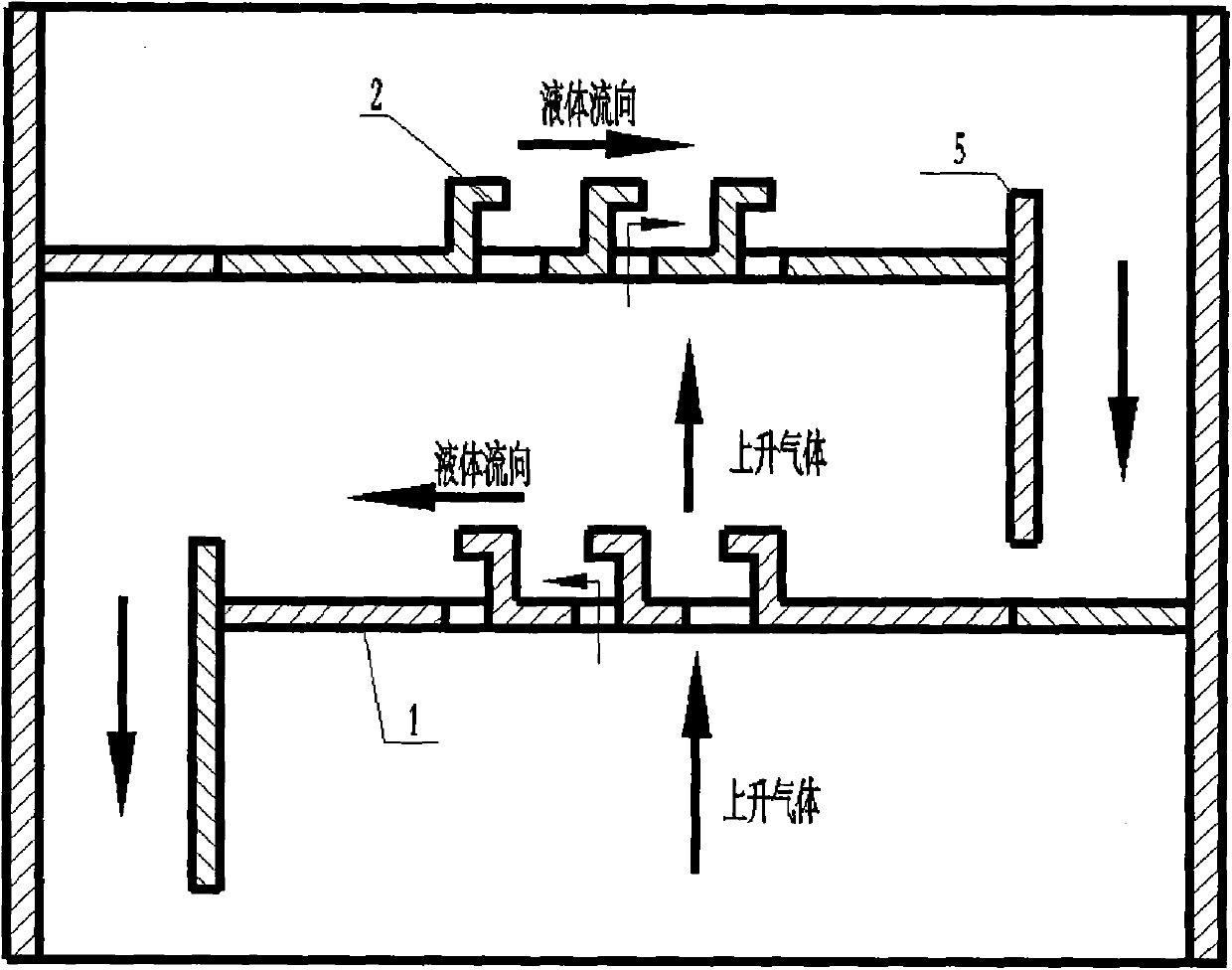

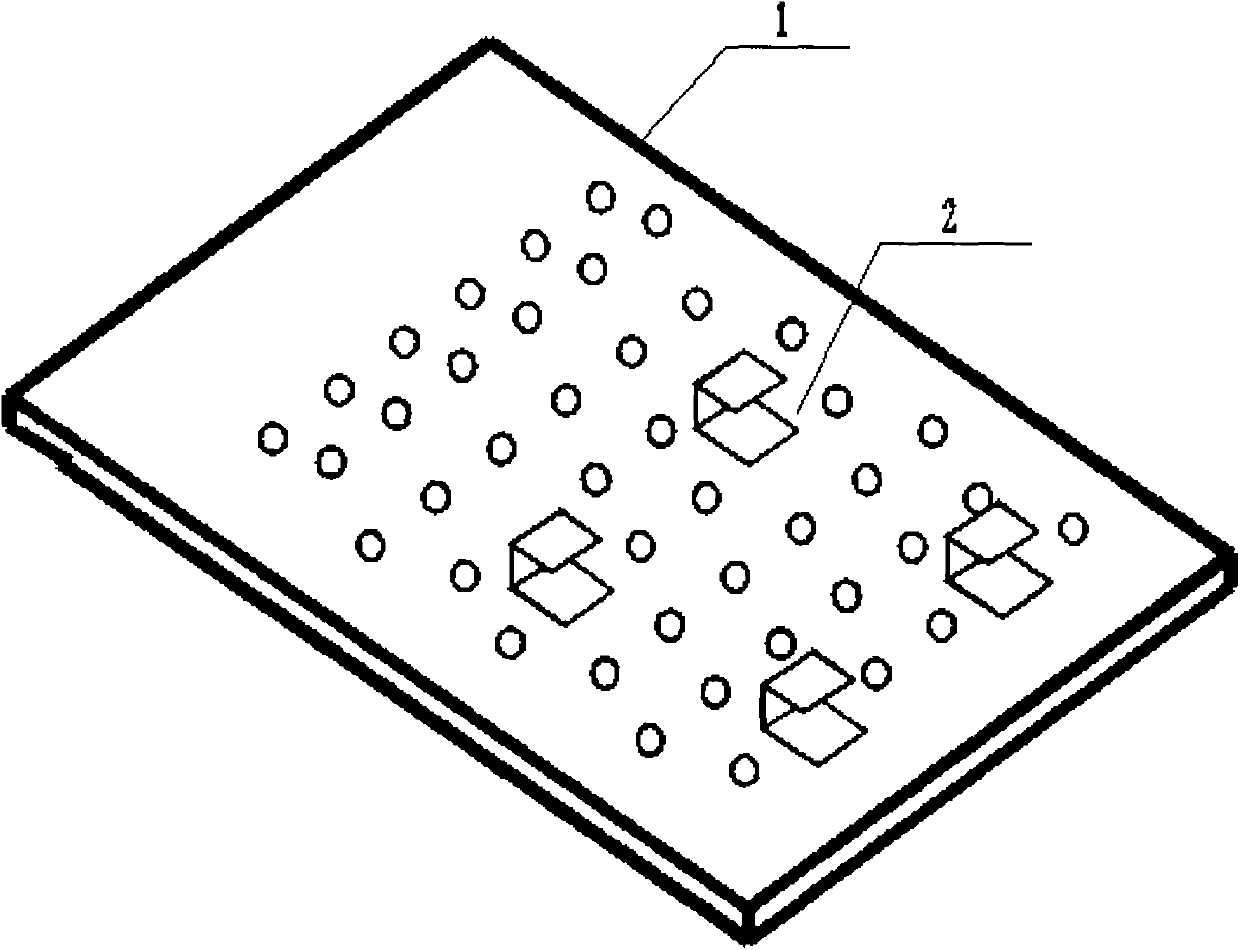

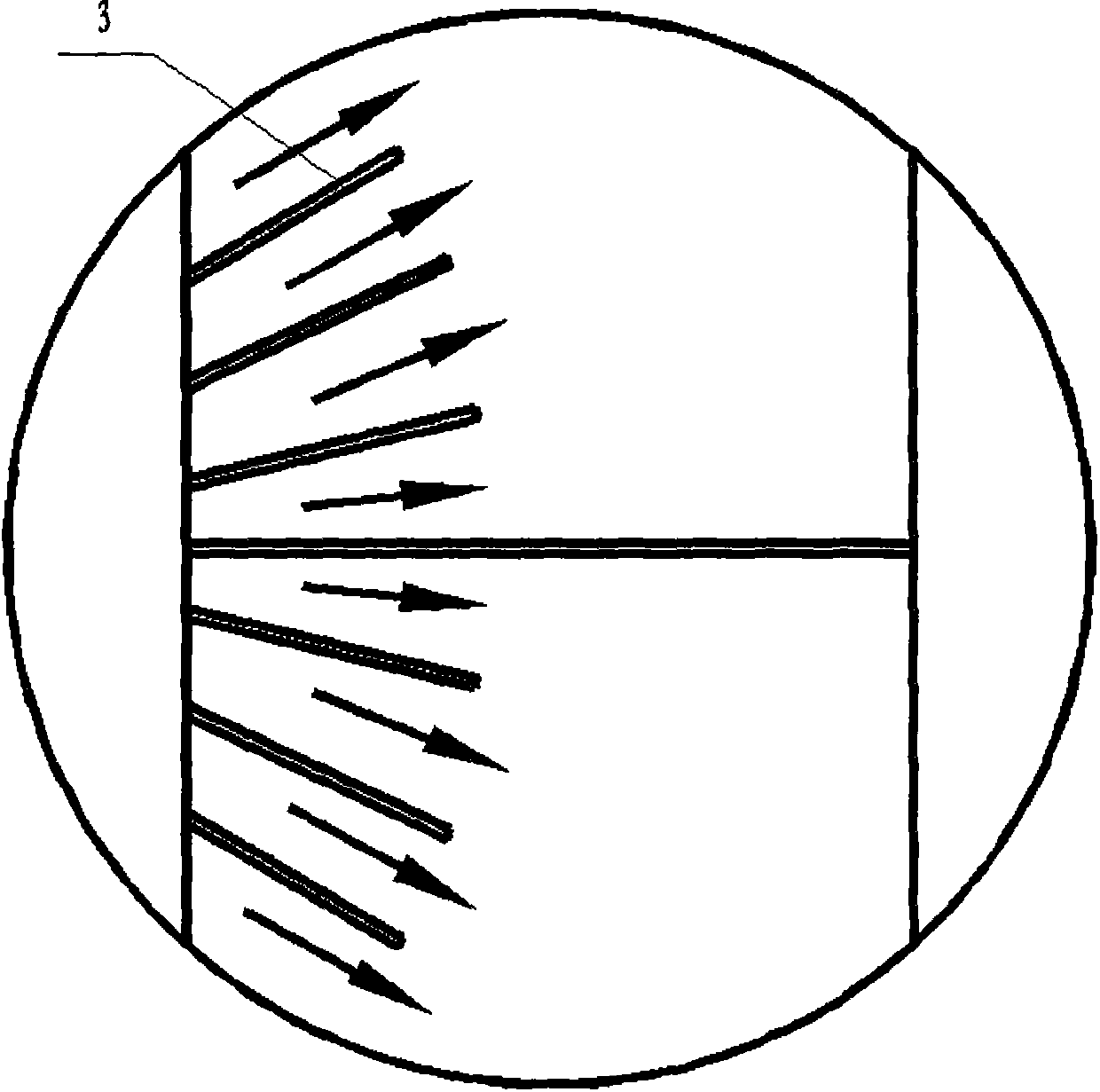

[0025] attached by Figure 1-6 It can be known that a gas-liquid guide tray of the present invention mainly includes guide holes, guide weirs, turbulence intensifiers, downcomer plates, and liquid receiving trays. It is characterized in that: the guide holes on the tray are bosses, and the guide The weir is set in the liquid phase inlet area, the turbulence intensifier is a special-shaped obstacle, and the downcomer plate is a broken line downcomer plate. The specific working process of the tray of the present invention is as follows: the liquid phase flowing down from the upper tray flows down along the downcomer formed by the broken-line downcomer to form a certain liquid seal height to ensure that there is a certain volume in the downcomer. Liquid, the liquid phase passes through the turbulence intensifier at the entrance of the liquid phase of the tray, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com