Automatic pipe cutter based on embedded integrated system

An integrated system and automatic cutting technology, applied in the direction of metal processing, etc., can solve the problems that the automatic classification and cutting of waste pipes cannot be realized, the degree of automation is not high, and the labor production efficiency is affected, so as to reduce the selection and processing procedures, improve production efficiency, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

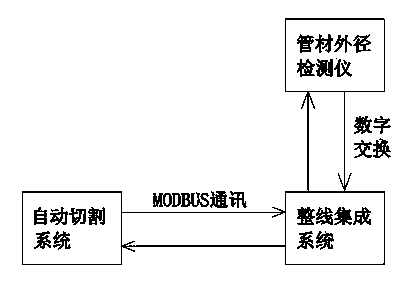

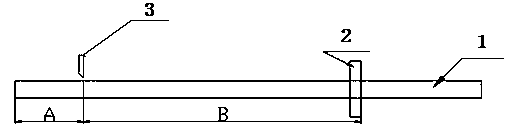

[0016] Such as figure 1 As shown, an automatic pipe cutting machine based on an embedded integrated system includes a frame, a meter wheel, a pressing device and a cutting machine. The cutting machine is provided with an automatic cutting system. In addition, it is also provided with an automatic cutting system Integrated system for detection of signal connections. The detection integration system includes a whole line integration system and a pipe outer diameter detector, and the whole line integration system is connected to the pipe outer diameter detector by signal; the automatic cutting system is connected to the whole line integration system by signal. Choose CTS-266PLC to embed the entire cutting control program into the whole line integration system through MODBUS communication 2 (MODBUS communication 2 is a standard open communication protocol), and the whole line integration system CTS7-266 and the pipe outer diameter quality detector digital signal exchange. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com