Method for preparing high-performance polyvinylpyrrolidone/silver selenide/nylon flexible composite thermoelectric film

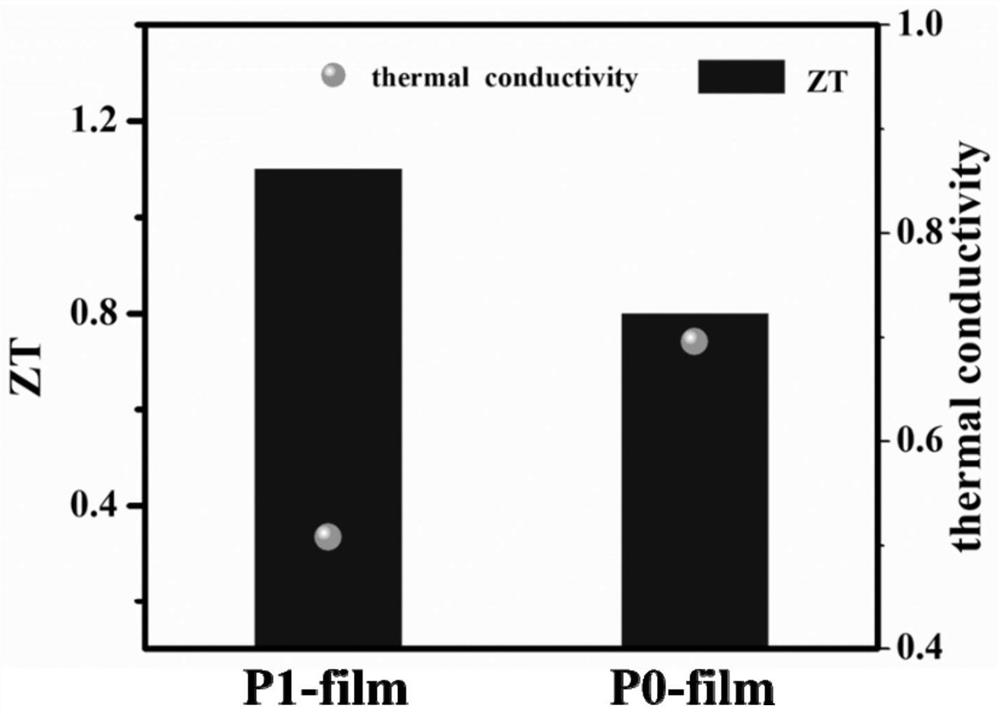

A technology of polyvinylpyrrolidone and thermoelectric thin film, which is applied in the manufacture/processing of thermoelectric devices, materials for junction leads of thermoelectric devices, nanotechnology for materials and surface science, etc., can solve the problem of non-flexibility and limit the application of flexible thermoelectric materials and other issues to achieve better flexibility, improved thermoelectric performance, flexibility, and enhanced electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

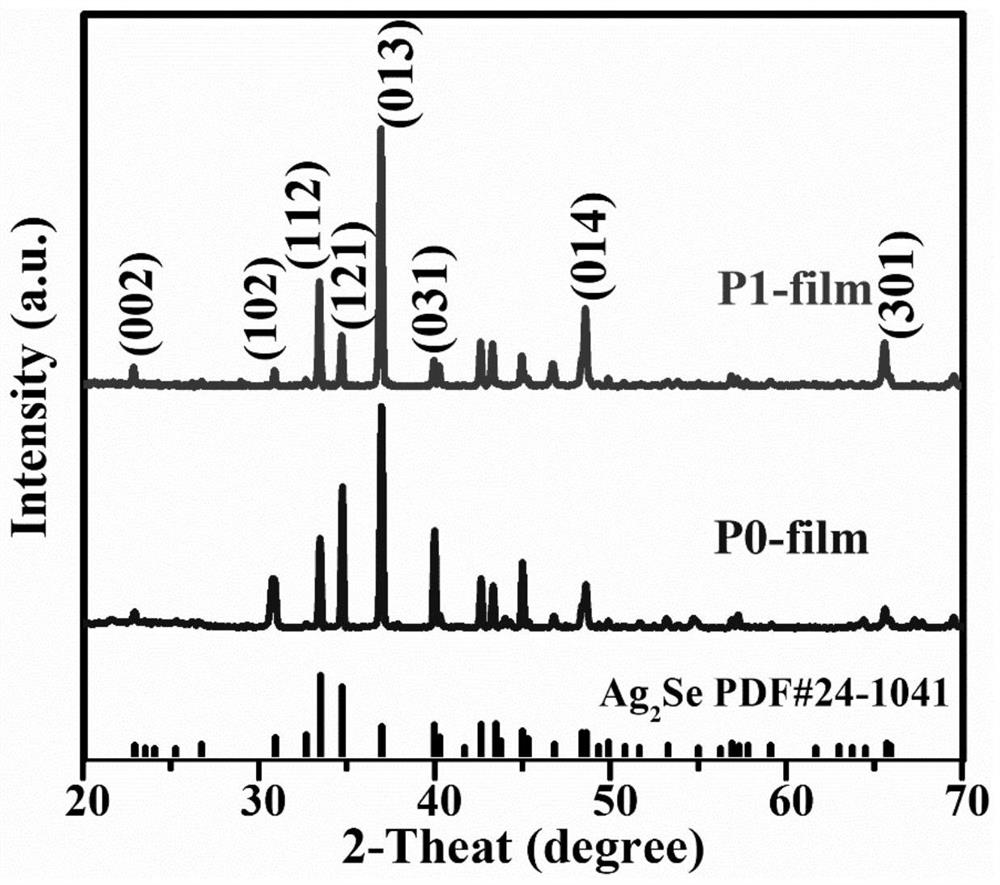

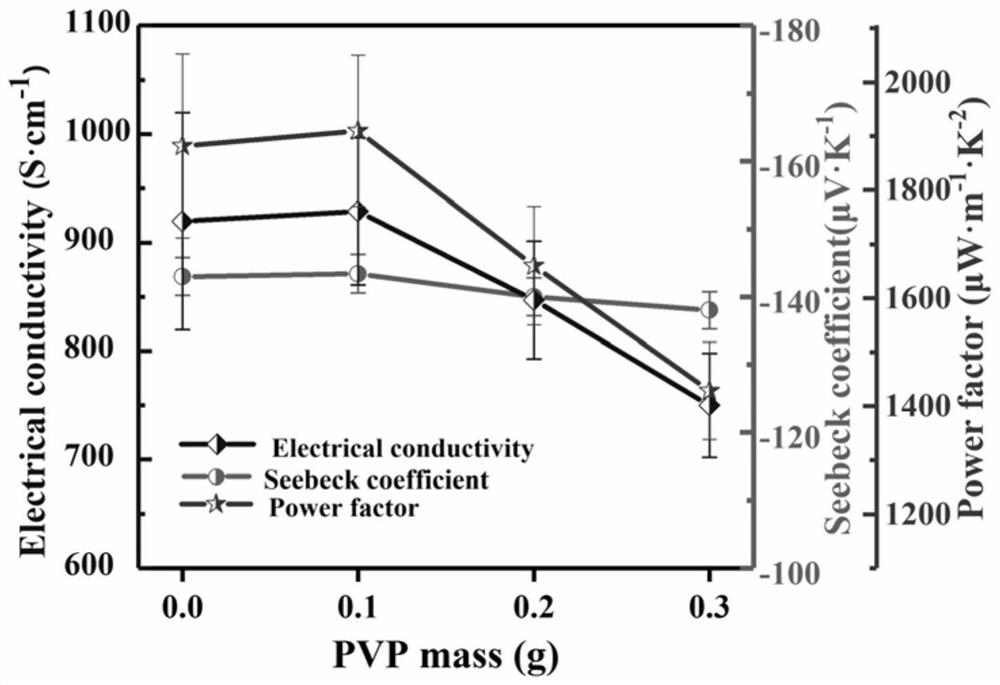

[0041]A method for preparing high-performance silver selenide / polyvinylpyrrolidone / nylon flexible composite thermoelectric film, the method is ethylene glycol dispersion (45mmol / L) of 20ml selenium nanowires, 0.612g silver nitrate (adding amount meets silver nitrate The molar ratio to the selenium nanowires is 4:1), 0.1g of polyvinylpyrrolidone and 80ml of ethylene glycol were added to the beaker, stirred at 40°C for 2h, centrifuged at a speed of 4000r / min, and the obtained black precipitate was extracted, and alternately Add deionized water and absolute ethanol and centrifuge at a speed of 4000r / min for 3 minutes to remove impurities. After centrifugation, disperse the carefully cleaned black target product in 15ml of absolute ethanol for 15 minutes, and then use a nylon filter membrane as a lining At the bottom, the silver selenide / polyvinylpyrrolidone / nylon flexible film was obtained by vacuum filtration, and the obtained film was dried in a vacuum drying oven at a temperatu...

Embodiment 2

[0050] A method for preparing high-performance silver selenide / polyvinylpyrrolidone / nylon flexible composite thermoelectric film, the method is with the ethylene glycol dispersion (45mmol / L) of 20ml selenium nanowire, silver nitrate (addition meets silver nitrate and selenium The molar ratio of the nanowires is 2:1), 0.1g of polyvinylpyrrolidone and 80ml of ethylene glycol were added to the beaker, stirred at 40°C for 1.5h, centrifuged at a speed of 4000r / min, and the obtained black precipitate was extracted, and added alternately Centrifuge deionized water and absolute ethanol at a speed of 4000r / min for 3 minutes to remove impurities. After centrifugation, disperse the carefully cleaned black target product in 15ml of absolute ethanol and ultrasonically disperse for 15 minutes, and then use a nylon filter membrane as a substrate , vacuum filtration to obtain a polyvinylpyrrolidone / silver selenide / nylon flexible film, and place the obtained film in a vacuum drying oven to dry ...

Embodiment 3

[0052] A method for preparing silver selenide / polyvinylpyrrolidone / nylon flexible composite film with high thermoelectric performance, the method will use the ethylene glycol dispersion (45mmol / L) of 20ml selenium nanowires, silver nitrate (addition meets silver nitrate and selenium) The molar ratio of the nanowires is 3:1), 0.1g of polyvinylpyrrolidone and 80ml of ethylene glycol were added to the beaker, stirred at 40°C for 2 hours, centrifuged at a speed of 4000r / min, and the obtained black precipitate was extracted, and added alternately to Ionized water and absolute ethanol were centrifuged at a speed of 4000r / min for 3 minutes to remove impurities. After the centrifugation, the carefully cleaned black target product was dispersed in 15ml of absolute ethanol for 15 minutes, and then the nylon filter was used as a substrate. The polyvinylpyrrolidone / silver selenide / nylon flexible film was obtained by vacuum filtration, and the obtained film was dried in a vacuum drying oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com