Microdot-effect wallpaper ink special for intaglio printing and preparation method thereof

A kind of gravure printing and micro-dot technology, applied in the direction of ink, application, household appliances, etc., can solve the problem of single function and achieve unique visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

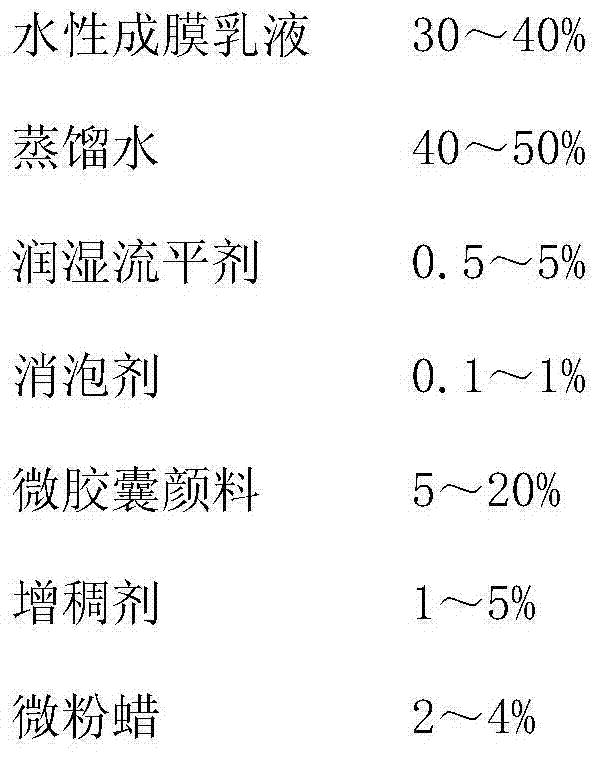

[0016] Embodiment 1, a micro-dot effect wallpaper ink dedicated to gravure printing described in this embodiment, it is obtained by adding the raw materials in the following parts by weight into a mixing tank, mixing and stirring uniformly:

[0017]

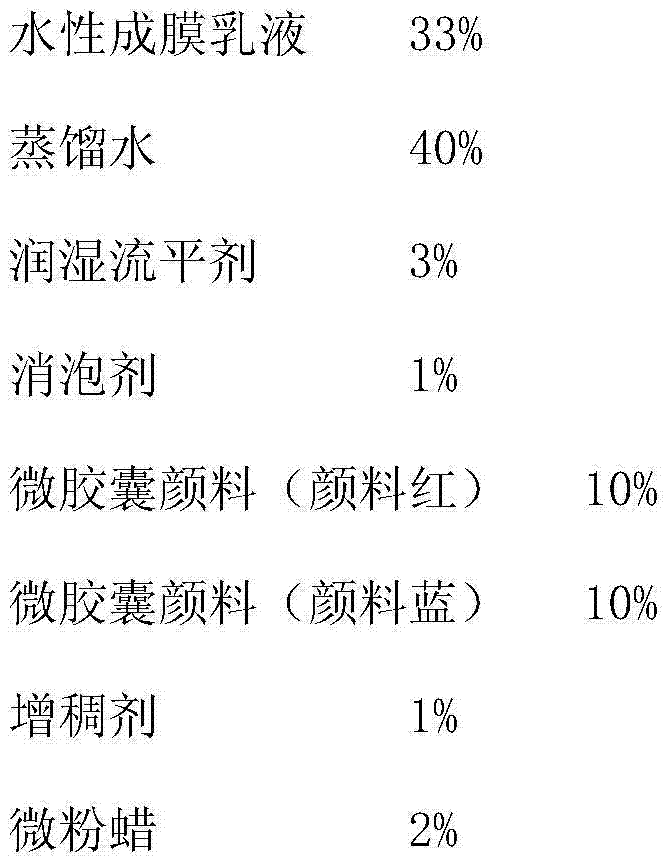

[0018] The water-based film-forming emulsion described in this example is a water-based acrylic emulsion produced by Green Spring (Xiamen) Environmental Technology Materials Co., Ltd., with a solid content of 47%, an acid value of 55, a glass transition temperature of 30°C, a pH value of about 8.5, and a viscosity of 800mPa.s ; Wetting and leveling agent is Flow425, polyether siloxane copolymer, effective content 100%, viscosity 100mPa.s; defoamer is Foamex K8, a mixture of aliphatic mineral oil, with an effective content of 100% and a viscosity of 100mPa.s; the microcapsule pigment is the MCPHP series of Hayashi Chemical Company, in which the red pigment model is GR4614, and the blue pigment is GR5315; the thickener is Vi...

Embodiment 2

[0020] Embodiment 2, a special micro-dot effect wallpaper ink for gravure printing described in this embodiment, it is obtained by adding the raw materials in the following parts by weight into the mixing tank, mixing and stirring uniformly:

[0021]

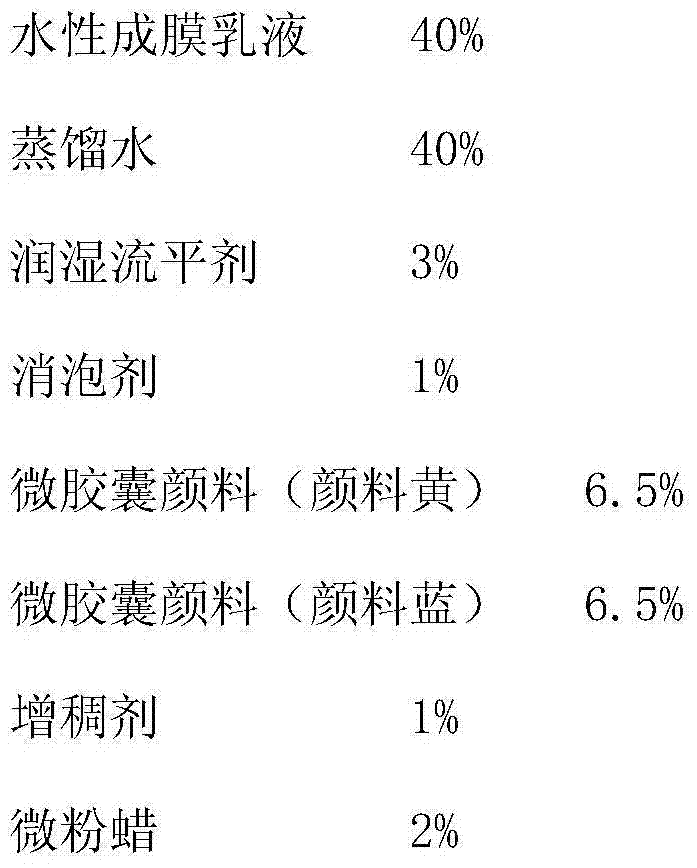

[0022] The water-based film-forming emulsion described in this example is a water-based acrylic emulsion produced by Green Spring (Xiamen) Environmental Technology Materials Co., Ltd., with a solid content of 47%, an acid value of 55, a glass transition temperature of 30°C, a pH value of about 8.5, and a viscosity of 800mPa.s ; Wetting and leveling agent is Flow425, polyether siloxane copolymer, effective content 100%, viscosity 100mPa.s; defoamer is Foamex K8, a mixture of aliphatic mineral oil, with an effective content of 100% and a viscosity of 100mPa.s; the microcapsule pigment is the MCPHP series of Hayashi Chemical Company, wherein the yellow pigment model is GY8308, and the blue pigment is GR5315; the thickener is ...

Embodiment 3

[0024] Embodiment 3, a micro-dot effect wallpaper ink dedicated to gravure printing described in this embodiment, it is obtained by adding the raw materials in the following parts by weight into a mixing tank, mixing and stirring uniformly:

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com