Scrapable formaldehyde closed film and preparation method thereof

A formaldehyde, coating technology, applied in the direction of coating, etc., can solve the problems of loose coating structure, limited sealing effect, poor permeability, etc., and achieve the effect of good gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

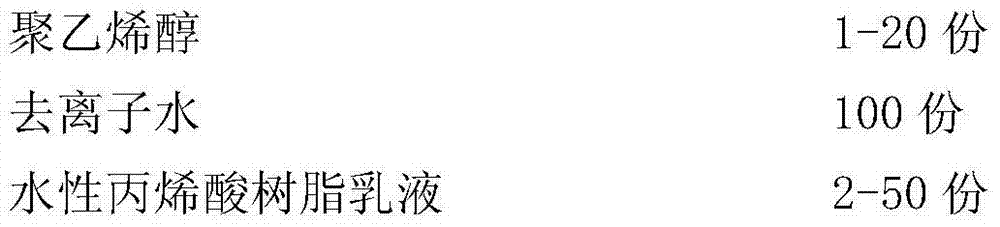

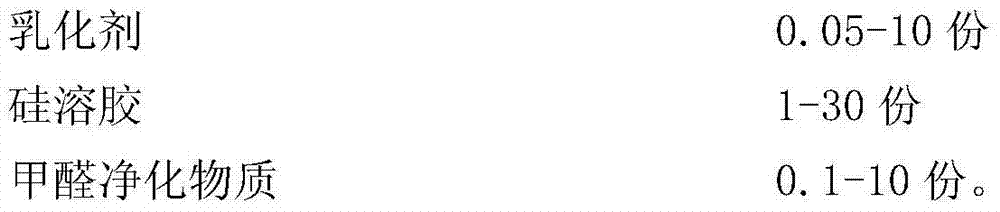

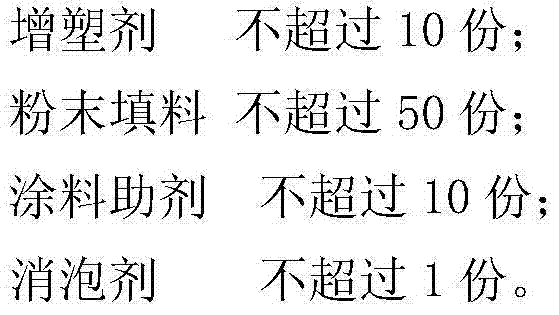

[0026] A removable formaldehyde sealing coating film, its raw material composition and addition amount are respectively:

[0027]

[0028]

[0029] A kind of preparation method of removable formaldehyde sealing film is carried out according to the following steps:

[0030] (1) Put 6g of polyvinyl alcohol and 90g of deionized water into container A and raise the temperature to 95°C and stir for 2 hours to dissolve;

[0031] (2) Add 10g of deionized water, 0.01g of defoamer, 10g of acrylic resin, 10g of colloidal silica, 1.5g of plasticizer, 1g of emulsifier, and 0.53g of paint additives into container B and stir well;

[0032] (3) Pour the liquid in container B into container A and stir thoroughly;

[0033] (4) Add the formaldehyde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com