Method for directional solidification extraction of ultra-high-purity aluminum under electromagnetic agitation

A technology of electromagnetic stirring and directional solidification, which is applied in the direction of improving process efficiency, etc., can solve the problems of low purification efficiency, no gas protection, secondary pollution, etc., achieve improved purification effect, small furnace space, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

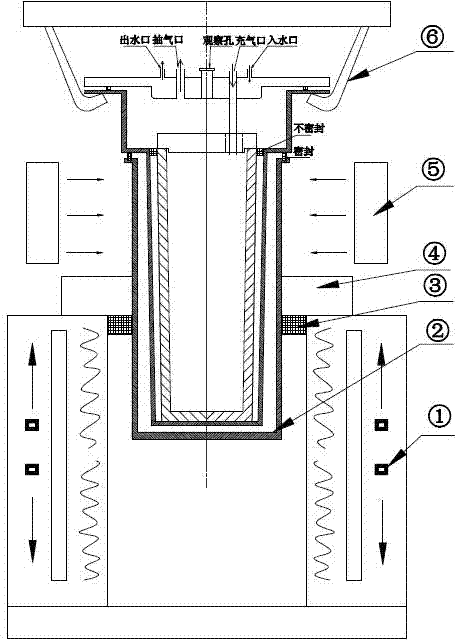

Method used

Image

Examples

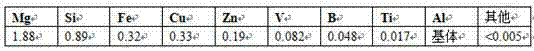

Embodiment 1

[0026] Embodiment 1: select the refined aluminum that purity is 4N6, in HF:HNO 3 : Soak in a solution of deionized water = 1:2:3 (mass ratio) for 10 minutes, then clean it with deionized water, and then dry it in an oven with the temperature set at 250°C; pack the dried original aluminum Put a high-purity graphite crucible with a diameter of 21cm and a height of 130cm into a fully enclosed furnace jacket to form a furnace, then put the furnace into an electromagnetic stirring heating furnace, first use a vacuum pump to evacuate the furnace, and then pass in argon Air to the atmospheric pressure value, so that the internal and external pressure of the furnace is balanced; at the same time, the electromagnetic stirring device is moved to the front of the solid-liquid interface of the aluminum liquid, and the aluminum liquid at the front of the solid-liquid surface is stirred axially, and the temperature of the aluminum liquid is kept at 680 ° C; Use the pulling device to slowly ...

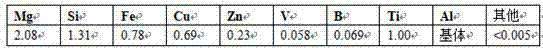

Embodiment 2

[0027] Embodiment 2: select the refined aluminum that purity is 4N3, in HF:HNO 3: Soak in a solution of deionized water = 1:2:3 (mass ratio) for 10 minutes, then clean it with deionized water, and then dry it in an oven with the temperature set at 250°C; pack the dried original aluminum Put a high-purity graphite crucible with a diameter of 21cm and a height of 130cm into a fully enclosed furnace jacket to form a furnace, then put the furnace into an electromagnetic stirring heating furnace, first use a vacuum pump to vacuum the furnace, and then pass in argon Air to atmospheric pressure to balance the pressure inside and outside the furnace; at the same time, move the electromagnetic stirring device to the front of the solid-liquid interface of the aluminum liquid, and carry out axial flow stirring of the aluminum liquid at the front of the solid-liquid surface, and the temperature of the aluminum liquid is kept at 720 °C; Use the pulling device to slowly pull the furnace out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com