Combined screw

A technology of screws and non-threaded parts is applied in the field of connectors, which can solve problems such as complex structures, achieve high creepage distance, realize automatic production and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

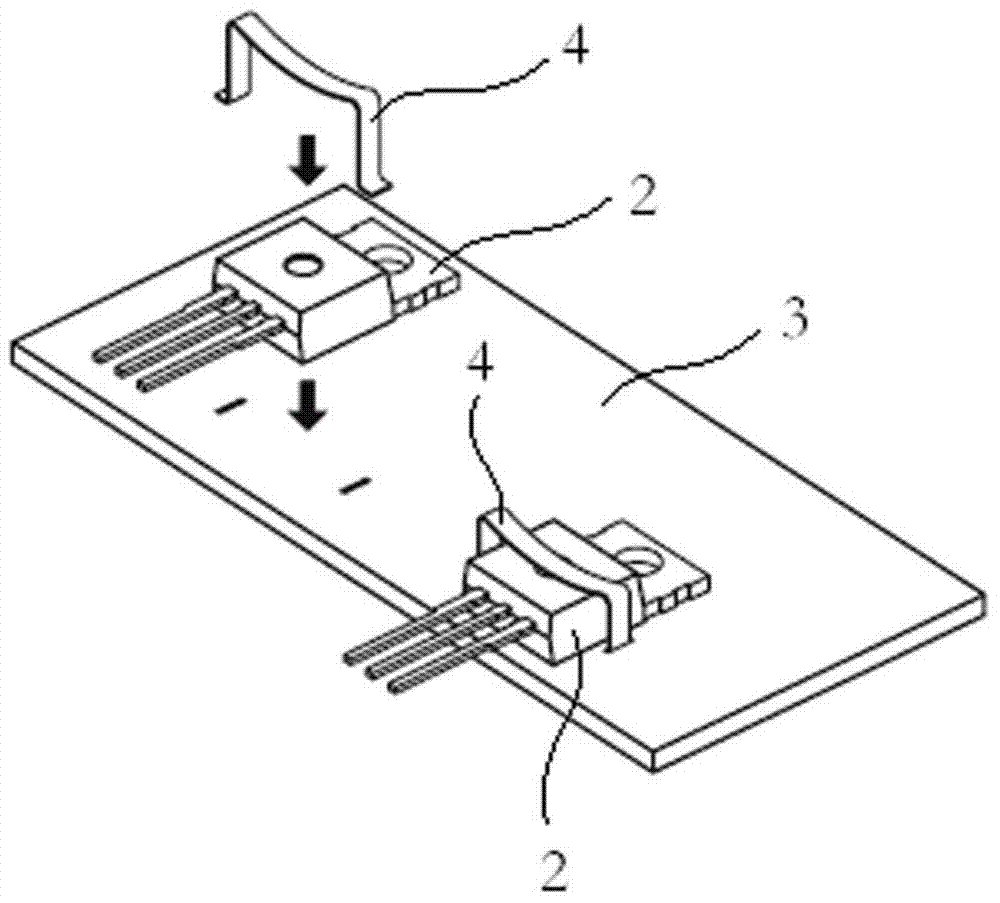

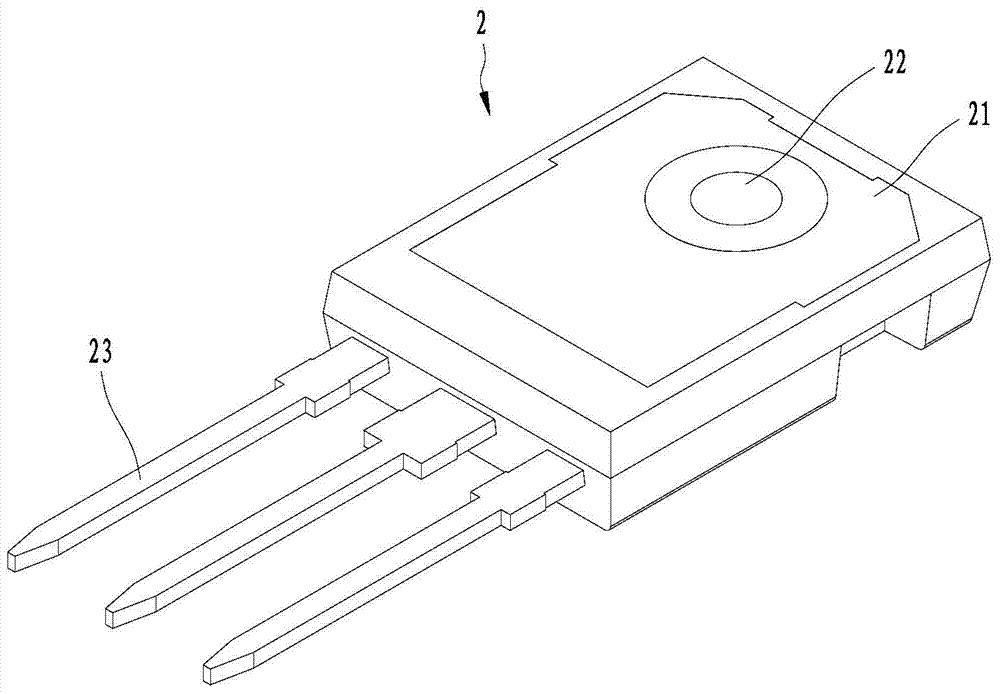

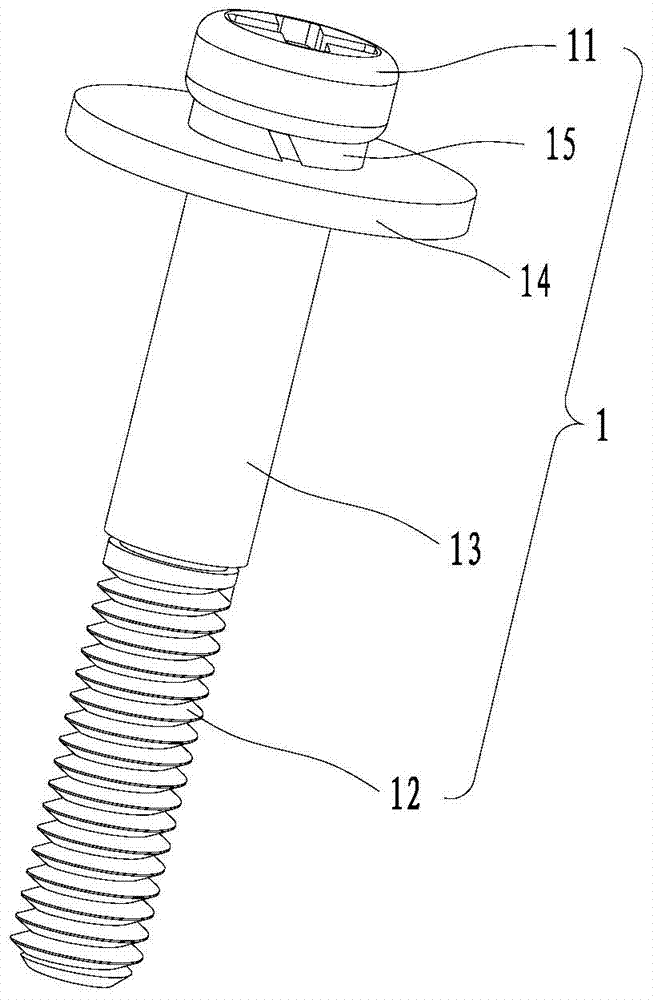

[0025] Such as image 3 , Figure 4 , Figure 5 as well as Figure 6 As shown, the preferred embodiment of the present invention provides a combination screw 1 for fixing the chip 2 on the heat dissipation base 3 . The combination screw 1 includes a head 11 and a shank 12 . One side of the chip 2 is provided with a heat sink 21, and the chip 2 also includes a fixing hole 22 set through the heat sink 21, and the fixing hole 22 extends from the side of the chip 2 provided with the heat sink 21 to the other opposite side. . When the combination screw 1 passes through the fixing hole 22 to fix the chip 2 on the heat dissipation base 3, the heat sink 21 and the heat dissipation base 3 are attached to each other to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com