Absorption refrigerator condenser based on heat tube bundle with coagulation strengthening function

An absorption refrigerator and condensation technology, which is applied in the direction of refrigerators, evaporators/condensers, refrigeration components, etc., can solve the problems affecting the performance of the unit, corrosion under the scale, and the unit cannot work, so as to facilitate the accumulation and whereabouts , simplified design and maintenance, reliable effect of cold source utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments. The vacuum pressure tank in this embodiment is square, and it can also be cylindrical or other shapes in other embodiments.

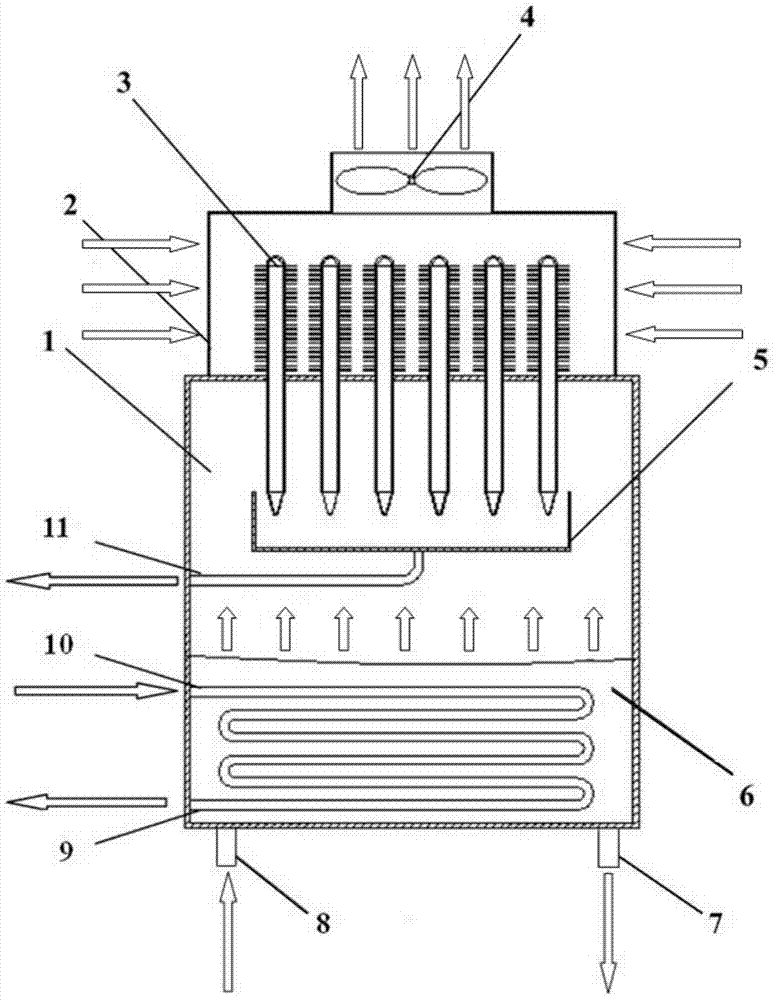

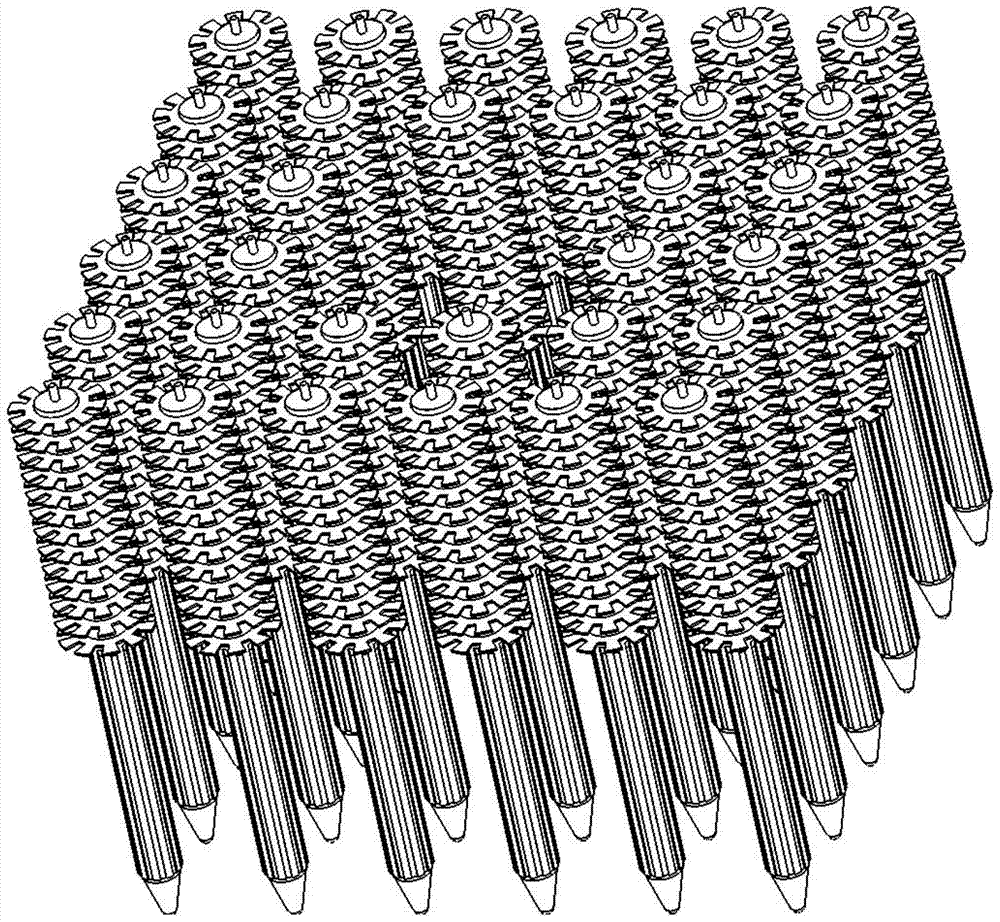

[0031] Such as figure 1 As shown, an absorption refrigerator condenser based on a heat pipe bundle with enhanced condensation effect includes a vacuum pressure tank, a heat pipe bundle, a diversion exhaust fan, a diversion wind cover and a condensed water container. The top of the vacuum pressure tank is provided with a diversion air cover isolated therefrom, and the diversion exhaust fan is installed directly above the diversion air cover. The heat pipe bundle is distributed in the middle position of the upper end of the vacuum pressure tank, and is also directly below the diversion exhaust fan. The evaporation sections of all the heat pipes in the heat pipe bundle are located inside the vacuum pressure tank, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com