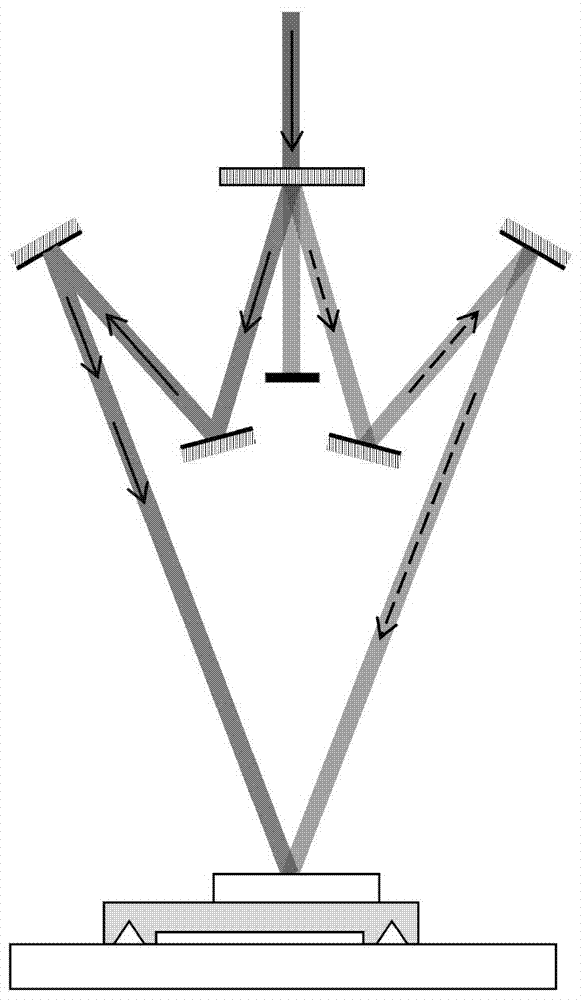

Method for precisely regulating direction of interference fringes in scanning exposure light path

A scanning exposure and interference fringe technology, applied in the field of spectroscopy, can solve the problems of erasure of grating lines, increase of line width, and reduction of exposure contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

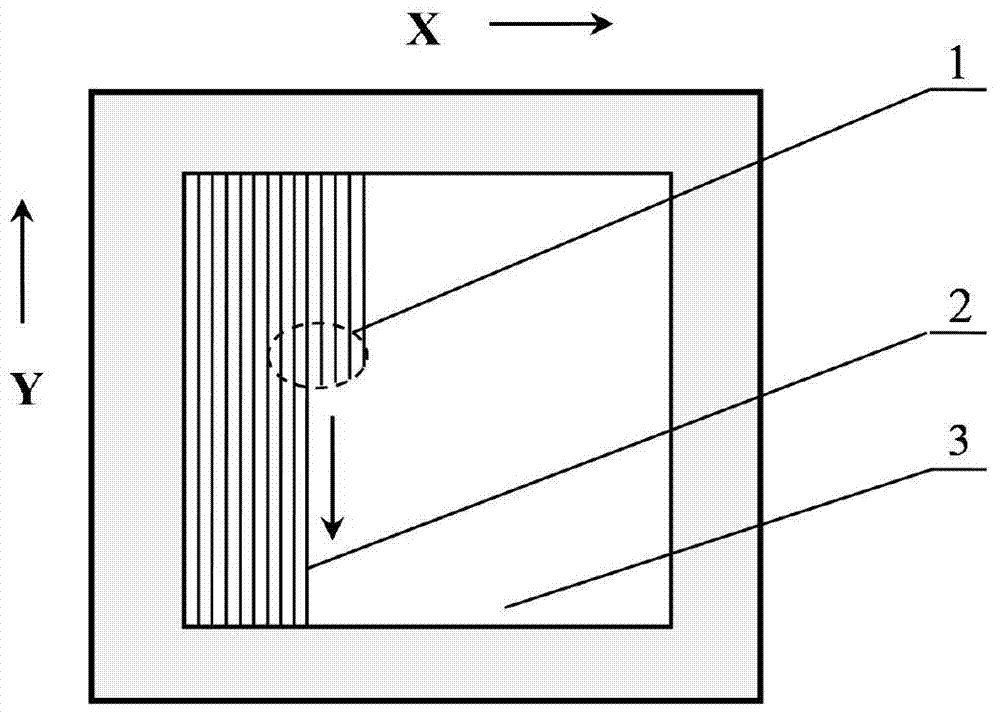

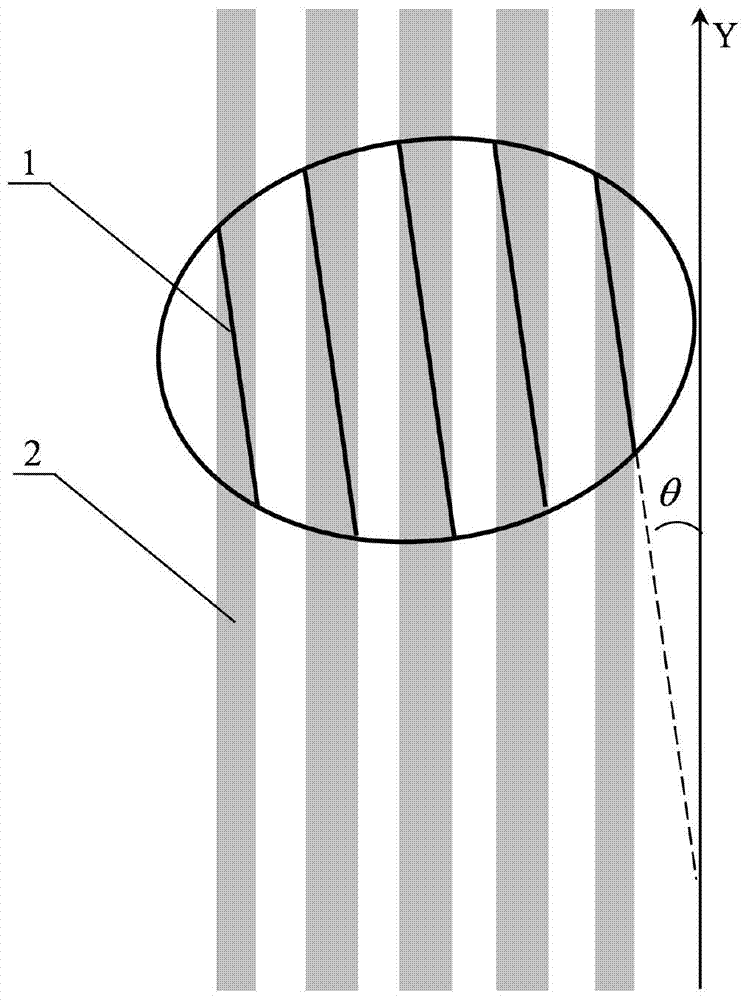

[0017] Specific implementation mode 1. Combination Figure 4 and Figure 5 Describe this embodiment, a method for precisely adjusting the direction of interference fringes in the scanning exposure optical path, the method is implemented by the following steps:

[0018] Step 1. Place the reference grating on the two-dimensional motion workbench. Figure 4 It is a top view of the two-dimensional motion table, the grating substrate 3 to be exposed is placed on the two-dimensional motion table 4, and the double guide rails 5 and 6 in the scanning motion direction are perpendicular to the double guide rails 7 and 8 in the stepping motion direction. The workbench 4 is pulled by the linear motor and can move along the scanning direction and the stepping direction respectively. The planar straight line grating with the same period as the grating to be exposed is used as the reference grating, the reference grating 9 is placed on the workbench 4, the surface of the reference grating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com