An ultra-precision scanning coating and positioning photolithography equipment

A technology of positioning light and fine scanning, which is applied in the direction of microlithography exposure equipment and photolithography exposure equipment, etc., can solve the problems of long processing cycle, large non-linear error error of graphics, complicated splicing process, etc., and achieve fast driving speed, The effect of improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

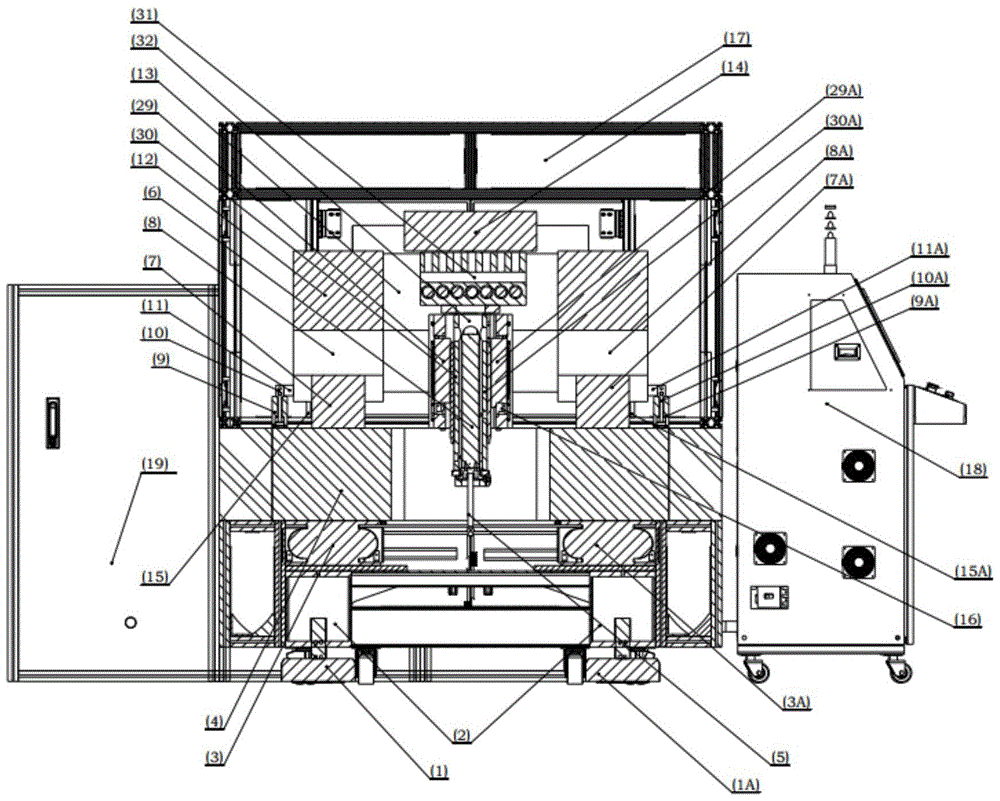

[0021] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0022] The levelness of the equipment can be adjusted through the leveling height step I1 and the leveling height step II1A set under the equipment support 2. The vibration damping system 3 is arranged on the upper part of the equipment support 2, and the granite base 4 is located on the low frequency air vibration damping system 3. The high-precision motion platform of the equipment is set on the precisely ground granite base 4, so that the vibration frequency of the high-precision motion platform is below 10Hz, eliminating the inherent vibration of the equipment and isolating the influence of the environment.

[0023] The cooling equipment and air filter equipment assembly 19 provides air sources for the air static pressure guide rail I7, the air static pressure guide rail II7A, the air static pressure slider I8, the air static pressure slider II8A and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com