Simulation test system and simulation test method for interface equipment of simulator in nuclear power station

A technology of simulation testing and interface equipment, which is applied in the field of testing, can solve the problems that the interface equipment detection is difficult to meet the requirements, and achieve the effects of easy expansion and upgrade, accuracy, and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

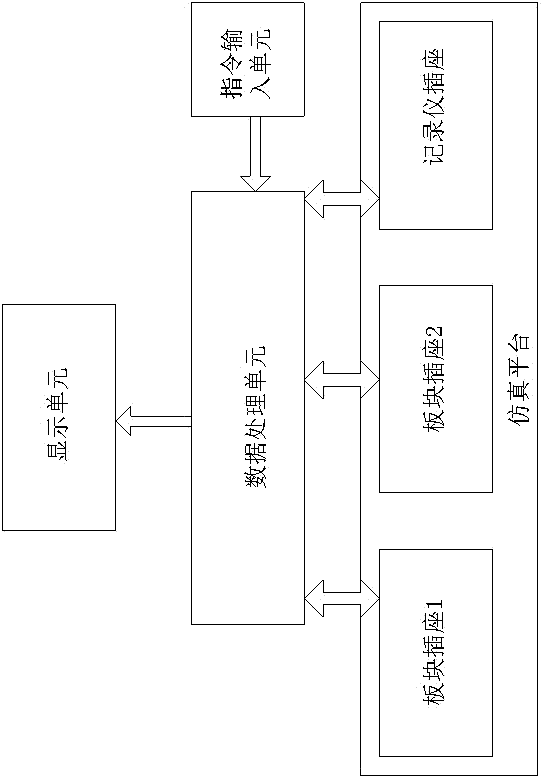

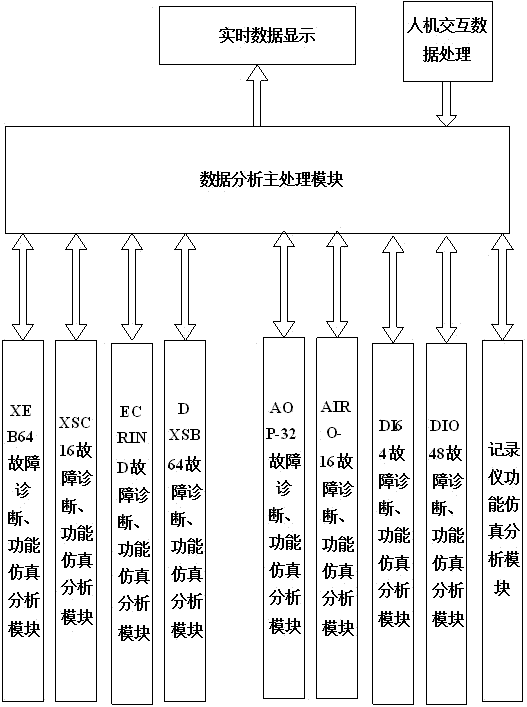

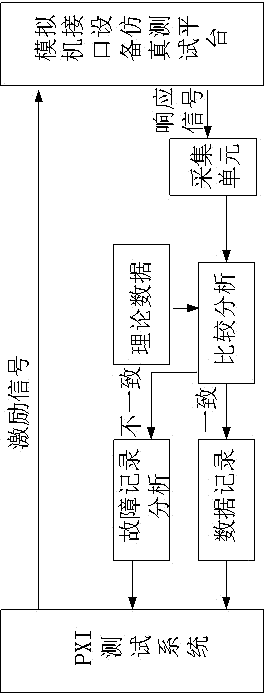

Method used

Image

Examples

Embodiment 1

[0015] Example 1: XSB64 board simulation test

[0016] Board function description: Daya Bay simulator interface board switch output,

[0017] 1. Test overview:

[0018] a) Insert the XSB64 board into the slot of the simulation platform of the simulator, select the type of test board, start to set the parameters and test, the XSB64 board receives 16-bit binary words through the bidirectional data bus and sends the selected data to the external interface, that is 16-bit data is given from B0-B15, and 4 words are output through different working states of WORD0, WORD1, WORD2, WORD3 of 8 CD4723 address latches (double 1 select 4 selection), and the signal logic is combined by 74C85 and 74LS10 For time-sharing control, the input signal is distributed through the resistance-capacitance network, and then the 64-bit data is reversely output through the 2N6660 OC gate (drive transistor), that is, various switching output signals on the analog console are executed.

[0019] b) Address...

Embodiment 2

[0028] Embodiment 2: XEB64 board simulation test:

[0029] Board function description: Daya Bay simulator interface board switch input.

[0030] 1. XEB64 board test:

[0031]a) Insert the XEB64 board into the slot of the simulation platform of the simulator, select the type of test board, start to set the parameters and test, the XEB64 board receives four 16-bit words through the data bus and adds them to the MC14539 multiplex data selection (double four selection One strobe), the selected 16-bit data is reversed level shifted by 4049, output to the data bus by the latch 74LS367, through the combination of bus timing signals, time-sharing control is performed by the logic combination of 74LS02 and HCF4585, and the data The signal of the switching value state on the bus is read into the CPU, and the switching value input signal of the simulator panel is sent to the computer system. After the test is completed, the test system is closed.

[0032] XEB64 PCB component failure i...

Embodiment 3

[0040] Embodiment 3: three-pen recorder simulation test;

[0041] 1. Three-pen recorder function description:

[0042] Data input waveform display area: analog simulation data input;

[0043] Data output simulation area: data simulation output, synchronized with the actual three-note recorder data output; insert the three-note recorder into the recorder interface of the simulator simulation platform, select the test recorder as the three-note recorder, and set the parameters as follows:

[0044] Range setting: recorder voltage output range: 0~10V, ±10V;

[0045] Mode setting: manual single-step test data or continuous automatic test data;

[0046] Level control: set the voltage value of the recorder, and the same value or different values of the three output signals can be selected;

[0047] Level amplitude: set the output voltage amplitude value of the three-way signal of the recorder;

[0048] Pointer rate: can be set to adjust the output data gain of the recorder;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com