Method for predicting friction coefficient of lubricants using special additives according to chemical structures

A technology of friction coefficient and chemical structure, applied in special data processing applications, electrical digital data processing, instruments, etc., can solve problems such as lack of theoretical guidance, achieve the effect of reducing risks and research costs, and improving development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

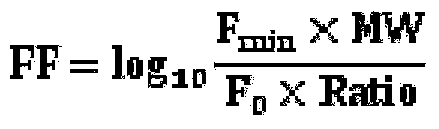

[0032] The technical solutions of the present invention will be clearly and completely described below in conjunction with specific embodiments. All the following examples are carried out in the SYBYL analysis software, a total of 30 lubricant additives, including triazine, benzothiazole, benzotriazole, benzotetrazolium and imidazole and other five core compounds as additive molecules , Disperse in the base oil liquid paraffin, carry out the tribological performance test, and obtain the average friction coefficient. The friction coefficient measurement is calculated using Equation 1.

[0033] The structure of the lubricant is generated in SYBYL and energy is minimized. The structural parameters we use include molecular performance parameters and quantum parameters. The calculation of all these parameters is carried out in DISCOVERY STUDIO software.

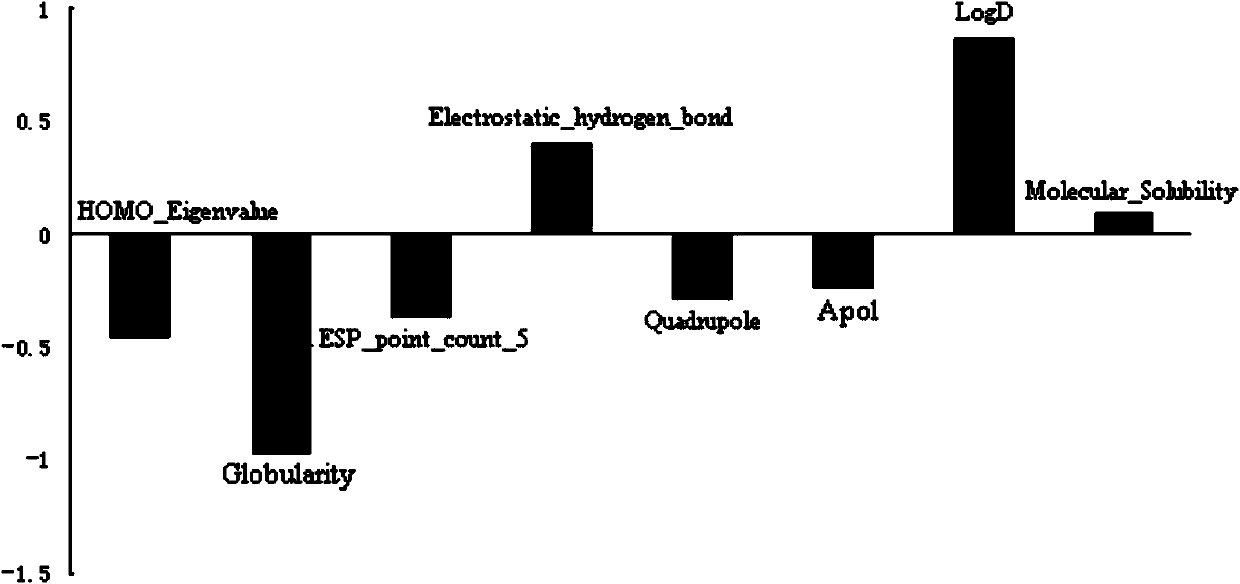

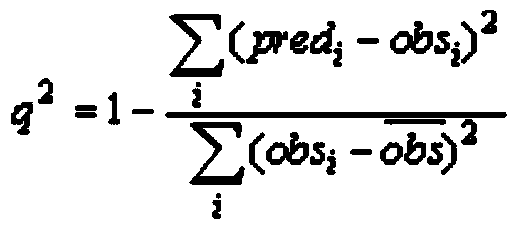

[0034] Artificial neural network is used for regression to study the relationship between friction coefficient measurement and str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com