Large-power boost circuit with high transformation ratio

A step-up circuit and high transformation ratio technology, applied in the direction of converting DC power input to DC power output, output power conversion devices, electrical components, etc. low grade issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

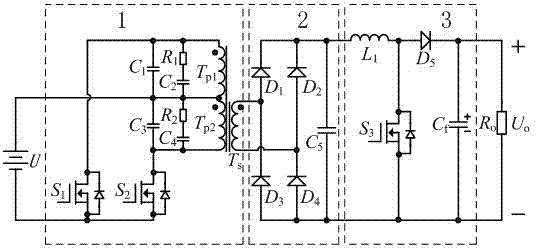

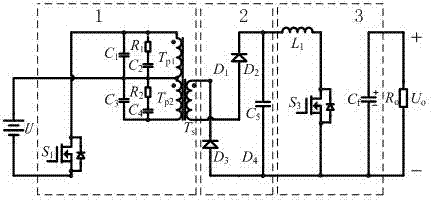

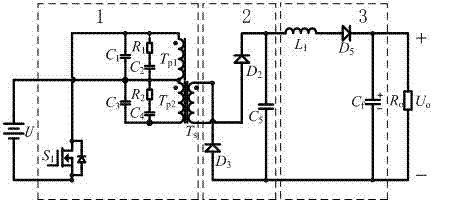

[0029] A high-power and high-transformation-ratio boost circuit includes: a front-stage push-pull boost sub-circuit 1, a rear-stage BOOST voltage-stabilizing sub-circuit 3, and an intermediate-stage resonant rectifier sub-circuit 2. The pre-stage push-pull boost sub-circuit 1 includes: the first power triode switch tube S 1 , the second power triode switch tube S 2 , the first primary winding T p1 , the second primary winding T p2 , the first absorption capacitor C 1 , the second absorption capacitor C 2 , the third absorption capacitor C 3 , the fourth absorption capacitor C 4 , the first snubber resistor R 1 , the second snubber resistor R 2 ; Intermediate resonant rectifier circuit 2, including: secondary winding T s , the first rectifier diode D 1 , second rectifier diode D 2 , the third rectifier diode D 3 , the fourth rectifier diode D 4 and resonant capacitor C 5 ; Post-stage BOOST voltage regulator sub-circuit 3, including: filter inductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com