Method and device for analyzing amount of sludge and removing contaminants in high-temperature and high-turbidity water system flow trough

A technology of flow trough and turbid water, applied in separation method, feeding/discharging device of sedimentation tank, chemical instrument and method, etc., can solve the problem of increasing labor intensity of on-site cleaning workers, low degree of automation on site, and health of cleaning personnel. Harm and other problems, to achieve the effect of broad market application prospects, simple transformation, low equipment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

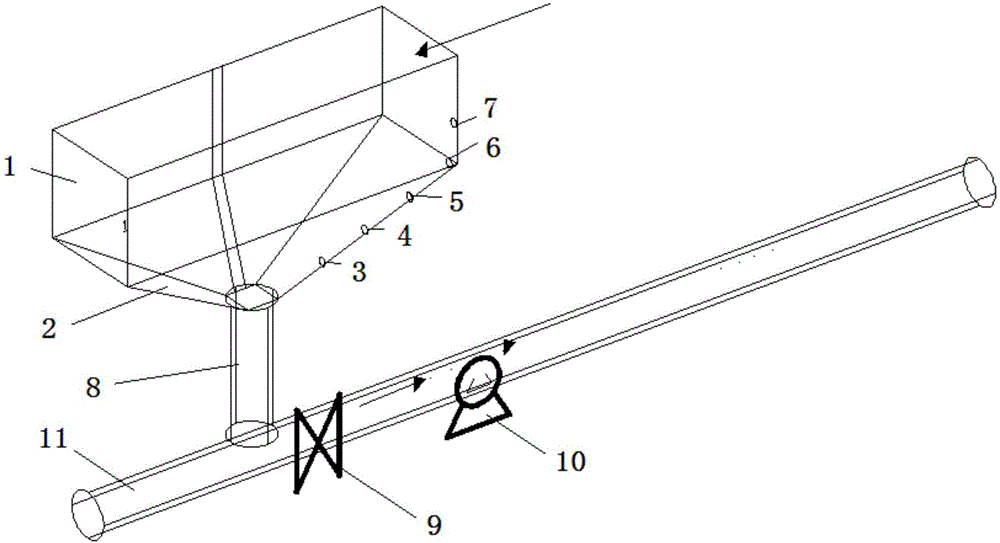

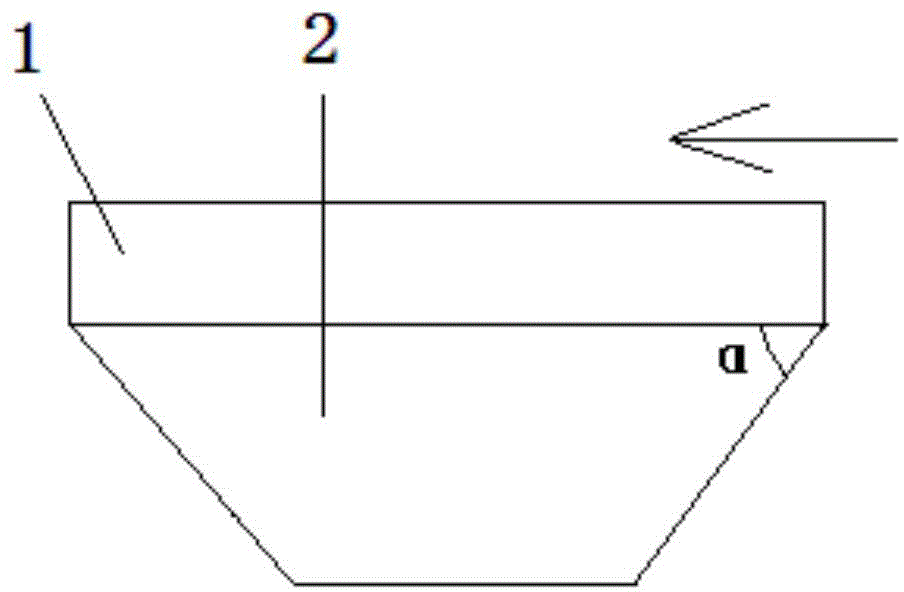

[0035] Below in conjunction with accompanying drawing, invention is further explained:

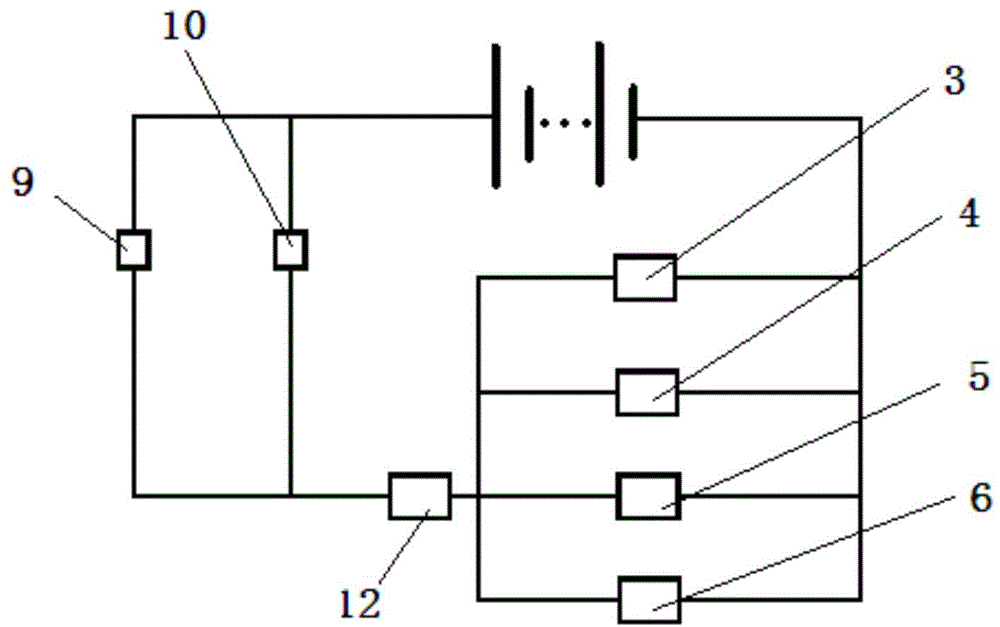

[0036] The concrete structure of device of the present invention sees figure 1 and figure 2 , the bottom of the launder 1 is provided with a cone bucket 2, and the angle a between the inclined wall of the cone bucket 2 and the bottom surface of the launder is 50-60 degrees. The bottom of the cone bucket 2 is connected to the sludge discharge pipe 11 provided with a mud discharge valve 9 and a mud pump 10 through a downcomer 8, and 4 electronic thermometers are evenly arranged on the side wall of the cone bucket 2 from bottom to top, Taking the vertical height h of the cone bucket 2 as the criterion, the four electronic thermometers are arranged from bottom to top on the side wall of the cone bucket. The electronic thermometer 5 at the height of 3 / 4h and the electronic thermometer 6 at the height of h are also provided with the electronic thermometer 7 on the trough at the same time, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com