Purification refined method for benzpyrole

A refining method and indole technology, applied in the direction of organic chemistry, can solve the problems of high production cost, gap, low indole yield, etc., and achieve the effect of increasing yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using indole with a purity of 92.0% as the raw material, according to the ratio of indole: hot water = 1:2, first add 50g of 92.0% indole into 100g of hot water at 90°C, stir and dissolve fully, and then the solution is layered. The upper layer solution was taken away and stirred at 15°C for 3 hours to crystallize, then the precipitated crystals were filtered, and the obtained filtrate was used mechanically. Extraction ends after one application. The crystals were dried in vacuum to obtain 43.1 g of white indole product with a purity of 99.92%, and the yield of indole reached 93.7%.

Embodiment 2

[0022] Using indole with a purity of 92.0% as the raw material, according to the ratio of indole: hot water = 1:1, first add 50g of 92.0% indole into 50g of hot water at 95°C, stir and dissolve fully, and then the solution is layered. The upper layer solution was taken away and stirred at 5°C for 2 hours to crystallize, then the precipitated crystals were filtered, and the obtained filtrate was used mechanically. Extraction ends after one application. The crystals were vacuum dried to obtain 43.8 g of white indole product with a purity of 99.92%, and the yield of indole reached 95.2%.

Embodiment 3

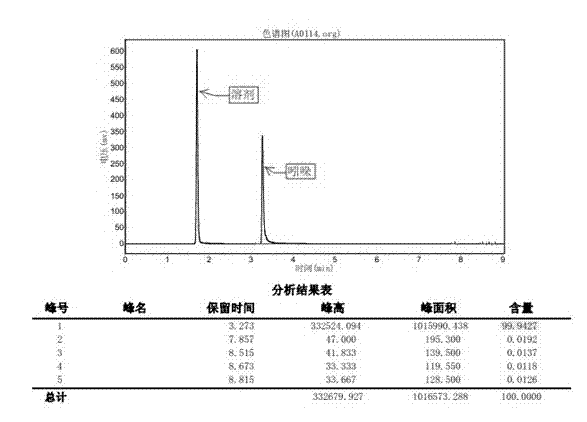

[0024] Using indole with a purity of 95.7% as the raw material, according to the ratio of indole: hot water = 1:0.5, first add 50g of 95.7% indole to 25g of hot water at 90°C, stir and dissolve fully, and then the solution is layered. The upper layer solution was taken away and stirred at 5°C for 2 hours to crystallize, then the precipitated crystals were filtered, and the obtained filtrate was used mechanically. Extraction ends after three applications. The crystals were vacuum dried to obtain a purity of 99.94% (such as figure 1 Shown) white indole product 45.9g, the yield of indole reaches 95.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com