A method of cooling molten iron by using converter dust removal ash

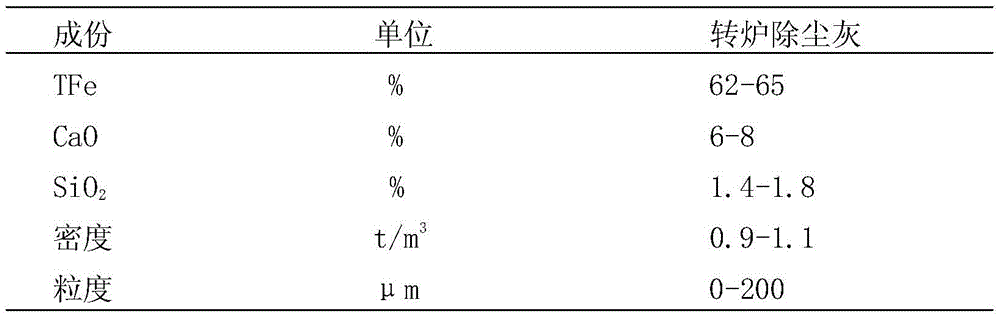

A technology for removing dust and molten iron from converters, which is applied in the field of pretreatment of molten steel in iron and steel metallurgy. It can solve problems such as difficulties in converter smelting operations and consumption of steel materials, and achieve the effects of accelerating slagging, saving production costs, and accelerating slagging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for cooling molten iron by utilizing converter dust removal ash, comprising steps as follows:

[0042] (1) Transport the collected converter dust to the silo for standby: use the HV700-18A special suction and discharge vehicle to collect the converter dust and transport it to the silo with high-pressure nitrogen for standby; the special suction and discharge vehicle is equipped with a high-pressure nitrogen source , the pressure range of the high-pressure nitrogen source: 25-30Mpa;

[0043] (2) Carry out KR desulfurization stirring treatment on the molten iron in the molten iron tank according to the prior art, the headroom height range of the molten iron tank is 500-900mm, and the molten iron amount in the molten iron tank ranges from 100-140 tons;

[0044] (3) After the KR stirring desulfurization treatment is completed, measure the temperature of the molten iron in the molten iron tank;

[0045] (4) When the measured temperature of the molten iron is greater ...

Embodiment 2

[0048] A kind of method utilizing converter dedusting dust to molten iron to cool down as described in embodiment 1, its difference is:

[0049] In the step (4), the measured temperature T of the molten iron is: at 1325°C, use high-pressure nitrogen to blow the converter dedusting ash weighing 2.2t from the feed bin into the molten iron tank, and add the converter dedusting ash to the molten iron Speed: 0.5t / min; the blowing pressure of the high-pressure nitrogen gas is 0.04MPa-0.05MP. At the same time, the agitator in the KR desulfurization stirring treatment process of the prior art is used to insert it into the molten iron tank for rotation and agitation to make the molten iron produce Vortex, the converter dedusting ash put into the molten iron surface is involved and fully mixed with the molten iron.

[0050] The temperature of the molten iron in the molten iron tank was monitored in real time, and the temperature of the molten iron dropped by 29°C to 1296°C within about ...

Embodiment 3

[0052] A kind of method utilizing converter dedusting dust to molten iron to cool down as described in embodiment 1, its difference is:

[0053] In the step (4), when the measured temperature T of the molten iron is 1387°C, the converter dedusting ash weighing 2.8t is blown from the feed bin into the molten iron tank by using high-pressure nitrogen gas, and the converter dedusting ash is added to the molten iron speed: 0.7t / min; the injection pressure of the high-pressure nitrogen gas is 0.04MPa-0.05MP, while using the agitator in the prior art KR desulfurization stirring treatment process, it is inserted into the molten iron tank for rotation and agitation, so that the molten iron A vortex is generated, and the converter dedusting ash put into the liquid surface of the molten iron is involved and fully mixed with the molten iron.

[0054] The temperature of the molten iron in the molten iron tank was monitored in real time, and the temperature of the molten iron dropped by 27...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com