Hydraulic process based on water-injection pump hydraulic system

A technology of hydraulic system and water injection pump, which is applied in the directions of fluid pressure actuating system components, fluid pressure actuating devices, mechanical equipment, etc. Harsh and other problems, to achieve the effect of adjustable displacement, long life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

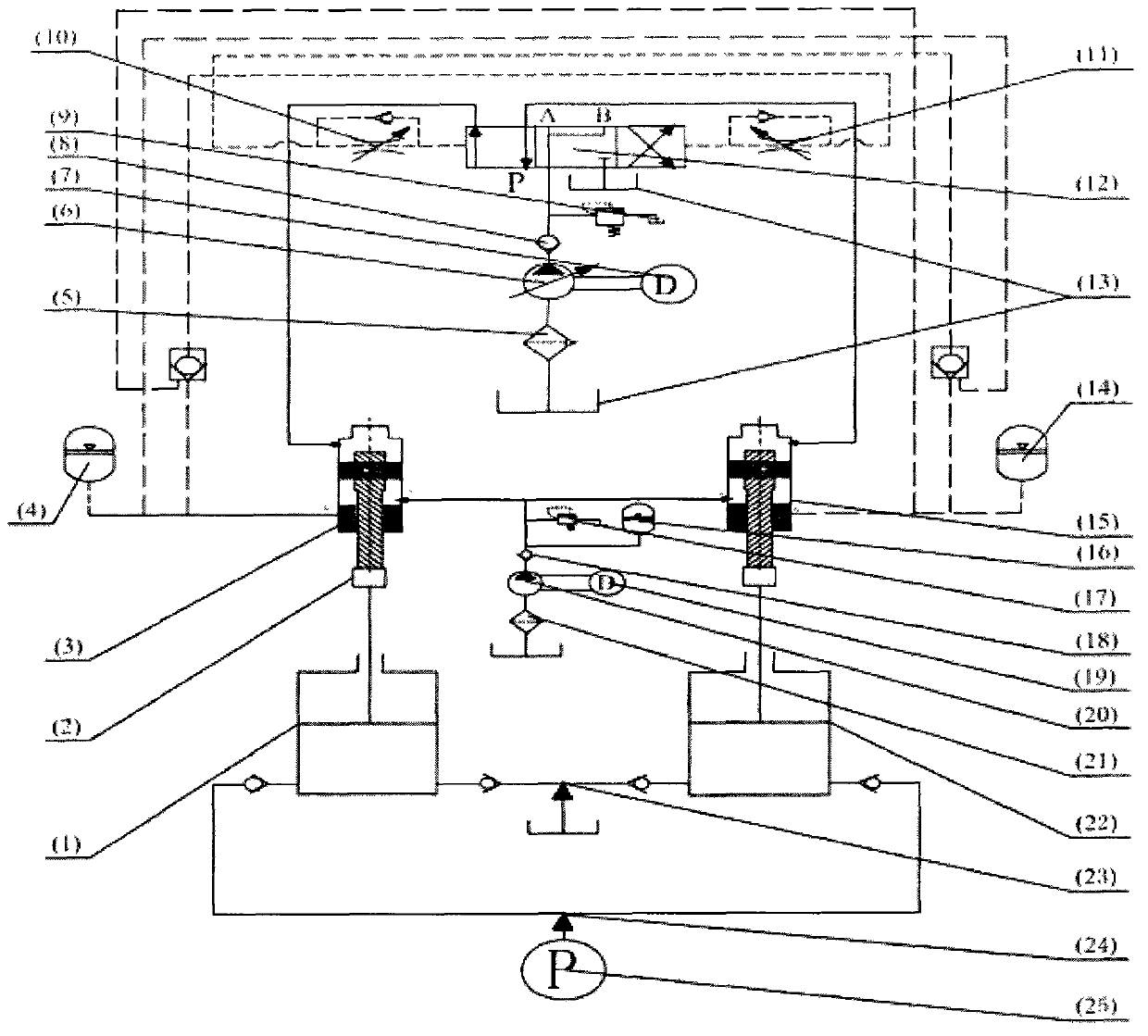

[0021] Such as figure 1 As shown, the hydraulic system used in the present invention includes a pump cylinder, a coupler connected with the pump cylinder, and a hydraulic cylinder connected with the coupler; the hydraulic cylinder is connected with a constant power variable pump, and the constant power variable pump is connected with a quantitative pump and An oil filter; the hydraulic cylinder is also connected with an accumulator and an oil filter; the constant power variable pump is provided with an overflow valve; the constant power variable pump is provided with a three-position four-way hydraulic control reversing valve.

[0022] figure 1 The solid line in the middle indicates the main oil circuit; the dotted line indicates the control oil circuit; the small flow pump and the accumulator 3 form an automatic replenishment circuit; the one-way throttle valve at both ends of the reversing valve controls the reversing time; the accumulators 1 and 2 act as auxiliary The powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com