Interface of a welding power source and method for defining the same

A welding power supply and interface technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high installation cost, long waiting time, and heavy load of welding manipulators, so as to avoid long-distance travel, avoid mistakes, and avoid serious accidents. the wrong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

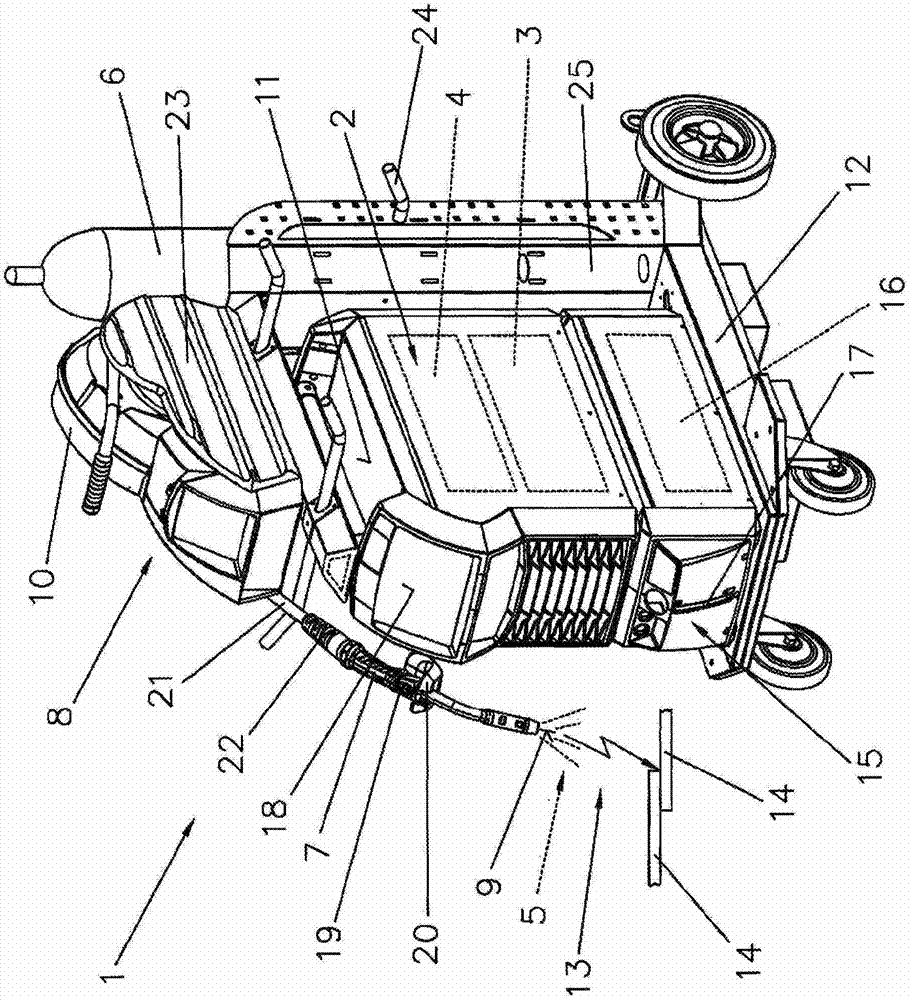

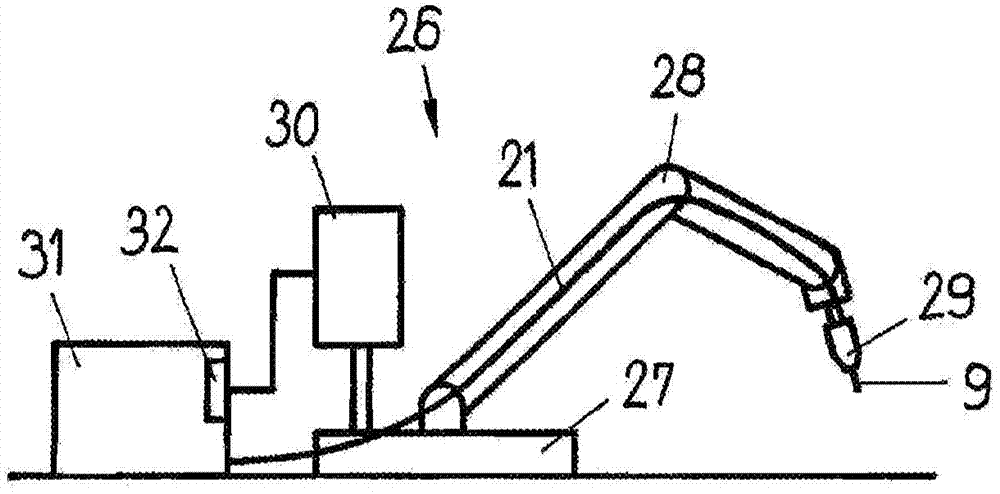

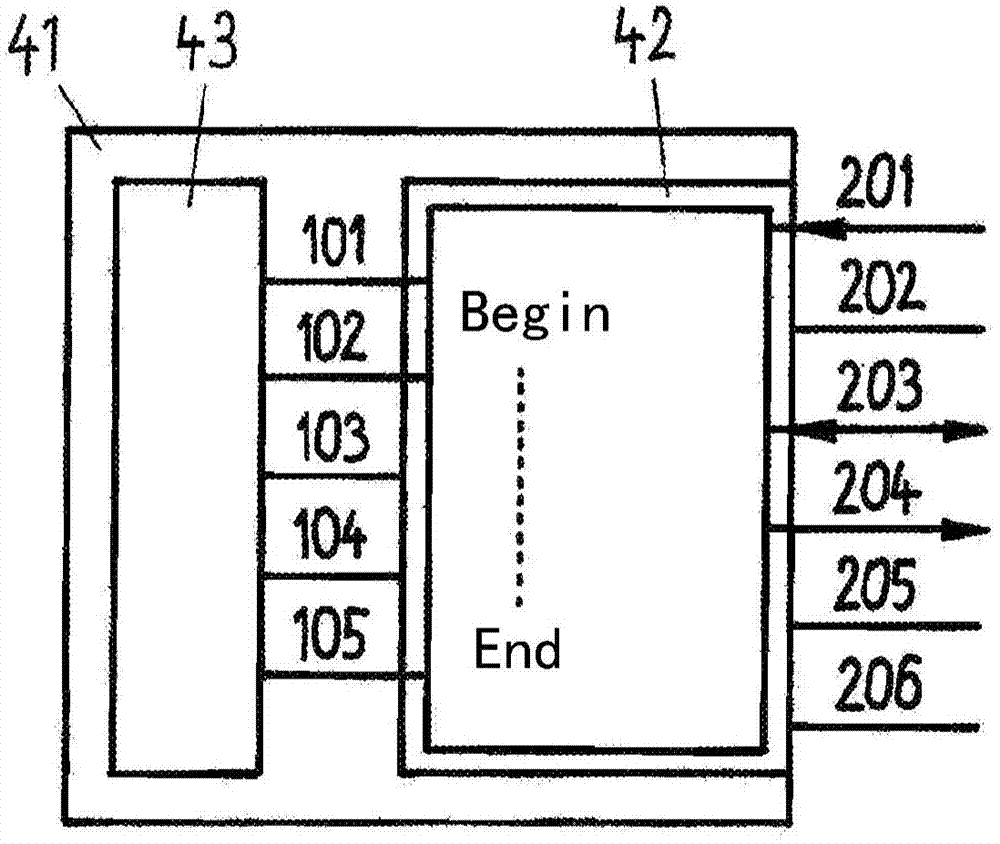

[0054] figure 1 A known welding device 1 or welding equipment is shown for different processes or methods such as MIG / MAG welding or WIG / TIG welding or electrode welding methods, twin wire / tandem welding methods, plasma or brazing methods etc. Wait.

[0055] The welding device 1 comprises a power source 2 having a power part 3 disposed therein, a control device 4 and other not-shown parts and lines, such as switching mechanisms, control valves and the like. The control device 4 is connected, for example, to a control valve which is arranged between the gas reservoir 6 and the welding torch 7 or torch in a supply line for a gas 5, in particular a shielding gas such as CO2, helium or argon, etc. between.

[0056] In addition, a wire feed 8 can also be activated via the control unit 4 , which is often used for MIG / MAG welding, wherein additional material or welding wire 9 is fed via a supply line from a storage reel 10 or wire coil to the area of the welding torch 7 middle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com