Secondary battery

A secondary battery and battery shell technology, applied in secondary batteries, secondary battery manufacturing, batteries, etc., can solve problems such as increased plate temperature, decreased heat dissipation of the plate, and decreased battery characteristics, achieving high energy density , high reliability, effective heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

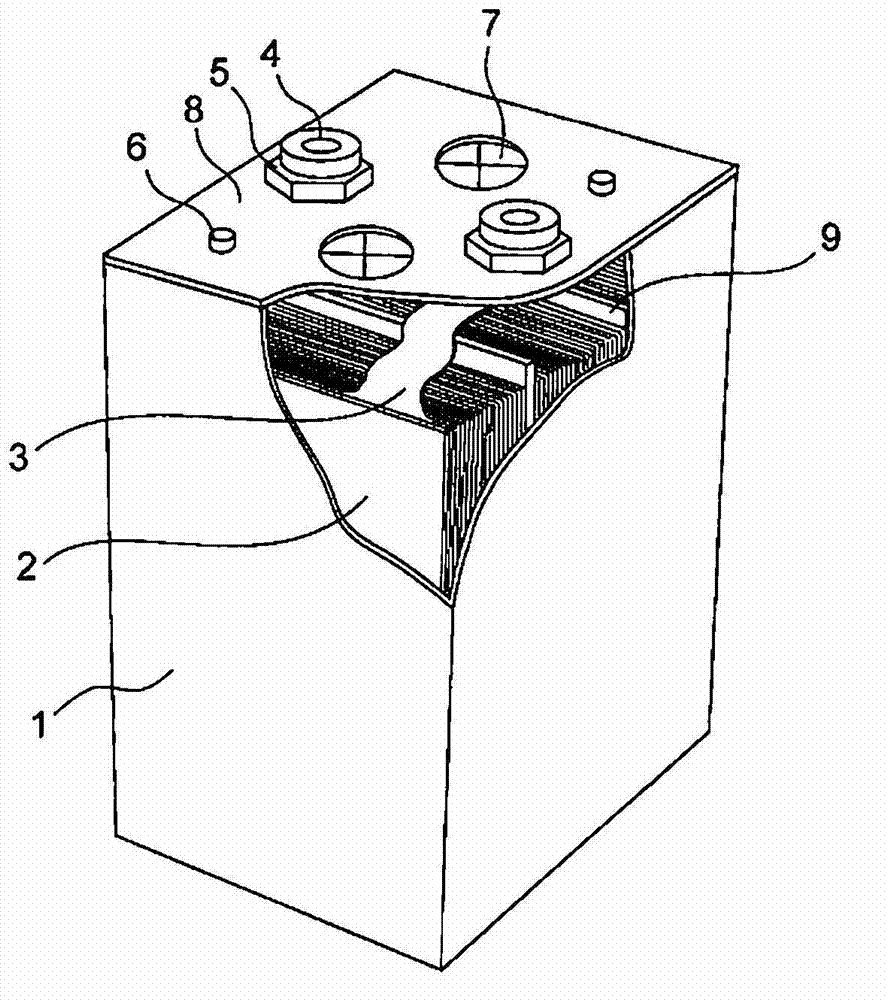

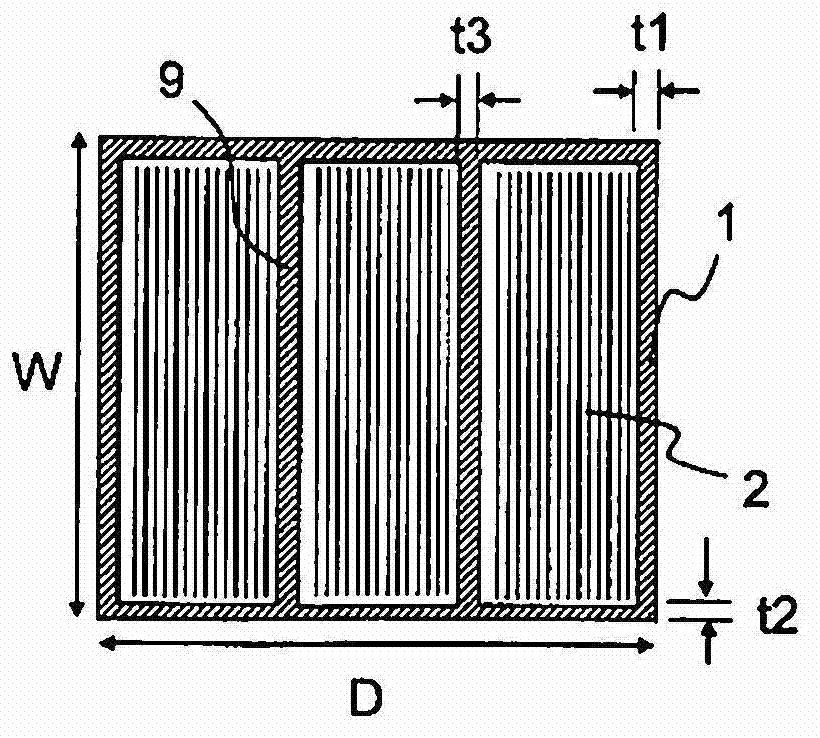

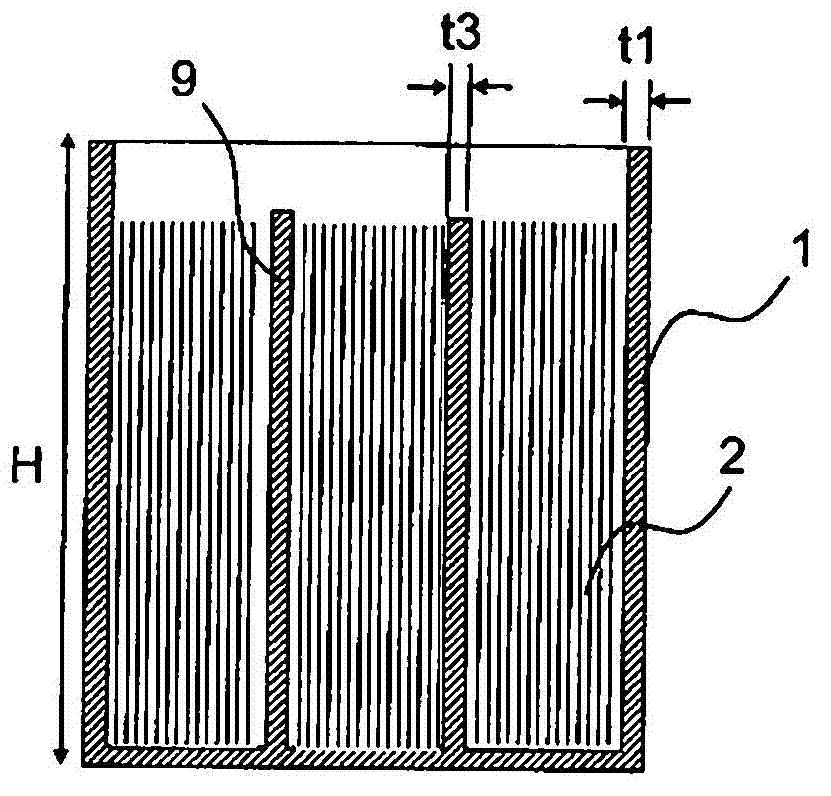

[0038] figure 1 is a partially cutaway perspective view showing a secondary battery according to an embodiment of the present invention, figure 2 yes figure 1 A schematic top sectional view of the secondary battery, image 3 yesfigure 1 A schematic side cross-sectional view of a secondary battery. exist figure 2 and image 3 In , the arrangement of the laminated body 2 and the battery case 1 of the present invention is shown, and tabs, covers, and current-carrying members of the laminated body are omitted. The illustration shows a stacked lithium-ion secondary battery with a battery capacity of 210Ah. The laminated body 2 is accommodated in the battery case 1 , and the laminated body 2 is electrically connected to the external terminal 4 via the tab 3 . The external terminal 4 is fixed to the cover plate 8 by fastening members 5 such as nuts. In addition, an injection hole plug 6 for closing the injection hole for injecting the electrolyte solution and a safety valve ...

Embodiment 2

[0046] Figure 4 It is a schematic plan cross-sectional view showing a secondary battery according to an embodiment of the present invention. Figure 5 yes Figure 4 A schematic side sectional view of the . This secondary battery is a 280 Ah laminated lithium ion secondary battery in which the laminated body 2 is composed of four sets. The capacity of one set of laminated bodies 2 is 70 Ah. The external dimensions of the battery case 1 are: the width W is 130 mm, the depth D is 205 mm, and the height H is 220 mm. The battery case 1 is composed of an outer peripheral body 11 made of stainless steel and a plurality of partition plates 9 . The partition plate 9 is fixed to the outer peripheral body 11 by welding. Such as Figure 5 As shown, compared with the outer peripheral body 11 of the battery case 1, the height of the partition plate 9 is lowered, and the bottom surface 11a of the outer peripheral body 11 of the battery case 1 is not in contact with the partition plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com