Seashell mining machine

An excavator and seashell technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of high purchase cost, easy damage, troublesome removal and cleaning, etc., to achieve fast mining, reduce labor intensity, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

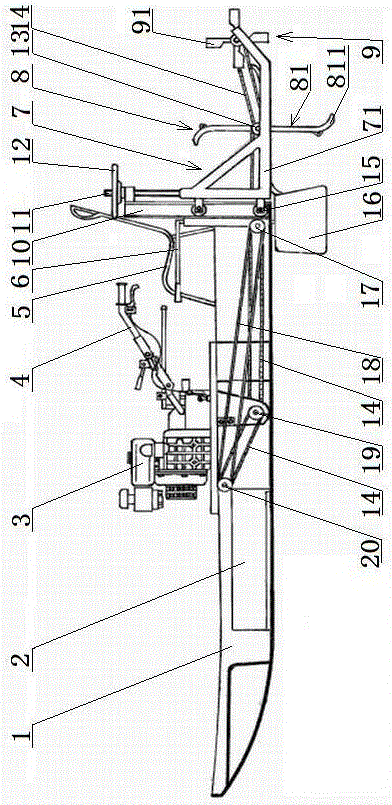

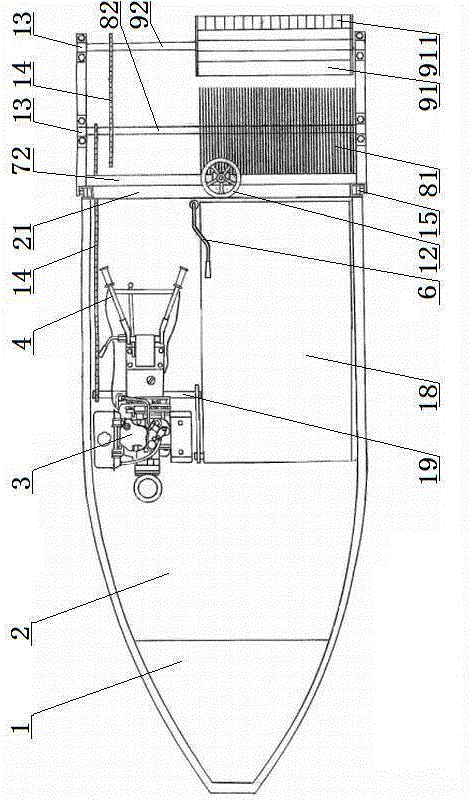

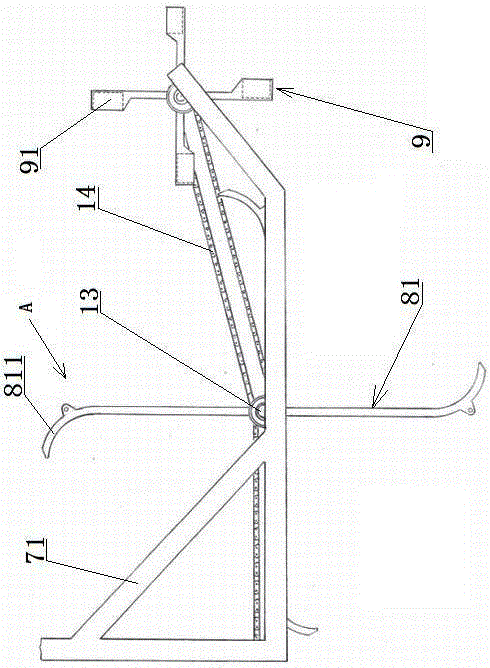

[0021] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

[0022] Such as Figure 1~Figure 6 As shown, 1. Hull, 2. Cabin, 3. Driving machine, 4. Handrail, 5. Seat, 6. Rudder stock, 7. Lifting frame, 71. Corner frame, 72. Ejector, 8. Mud filter wheel , 81. Claw row, 811. Elbow, 82. Clay wheel shaft, 9. Water throwing wheel, 91. Row groove, 911. Swinging water groove, 92. Water wheel shaft, 10. Guide groove, 11. Screw rod, 12. Lifting hand Wheel, 13. Bearing seat, 14. Chain transmission structure, 15. Pulley block, 16. Rudder, 17. Rear roller, 18. Conveyor belt, 19. Drive shaft, 20. Front roller, 21. Connecting rod, 22. Connecting bolt , 23. Isometric spacers.

[0023] Seashell mining machines, such as figure 1 , figure 2 As shown, it is a power mining machine designed on a ship-type vehicle. It mainly includes a small hull 1 for carrying people and transporting and storing seashell products. The hull can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com