Dexibuprofen injection composition

A composition and injection technology, applied in the field of medicine, can solve the problems of low bioavailability, low solubility, inconvenience to patients, etc., and achieve the effects of good stability, easy production control, and stable and safe preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

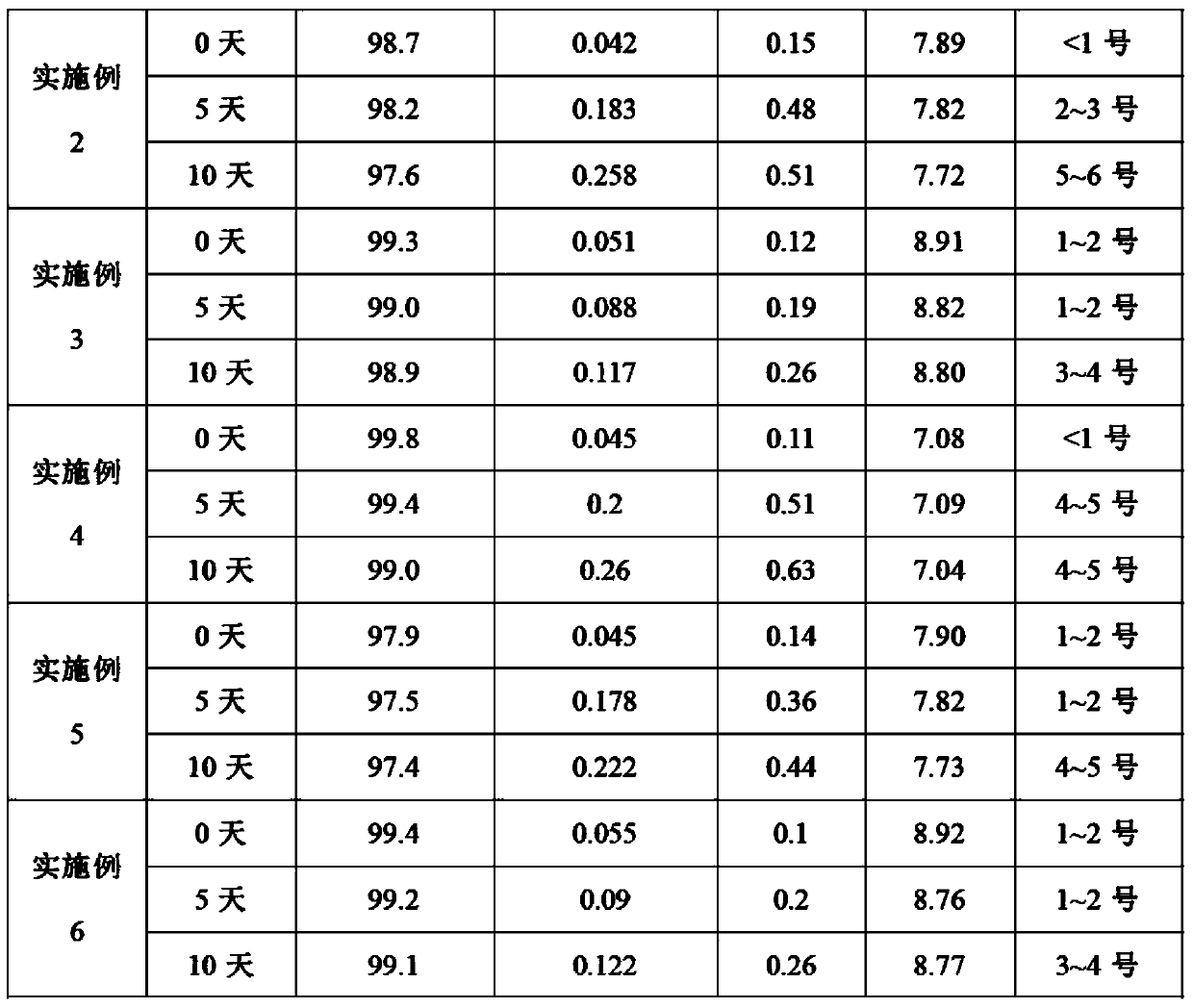

[0027] According to the formulation and preparation conditions in Table 1, different proportions of the dextroibuprofen compositions of Examples 1-6 (the content of dextrobuprofen in the formula is 100 mg / ml) were prepared by the following preparation methods.

[0028] Formulation and preparation conditions of table 1 embodiment 1-6 Dexibuprofen composition

[0029] test

Raw materials

The molar ratio of

concentration

Sterilization conditions

Example 1

Dexibuprofen: Arginine

1:0.82

100mg / ml

121℃ damp heat

Example 2

Dexibuprofen: Arginine

1:1.03

100mg / ml

121℃ damp heat

Example 3

Dexibuprofen: Arginine

1:1.30

100mg / ml

121℃ damp heat

Example 4

Dexibuprofen: Arginine

1:0.82

100mg / ml

121℃ damp heat

Example 5

Dexibuprofen: Arginine

1:1.03

l00mg / ml

121℃ damp heat

Example 6

Dexibuprofen: Arginine

1:1.30

100mg / ml

121℃ damp hea...

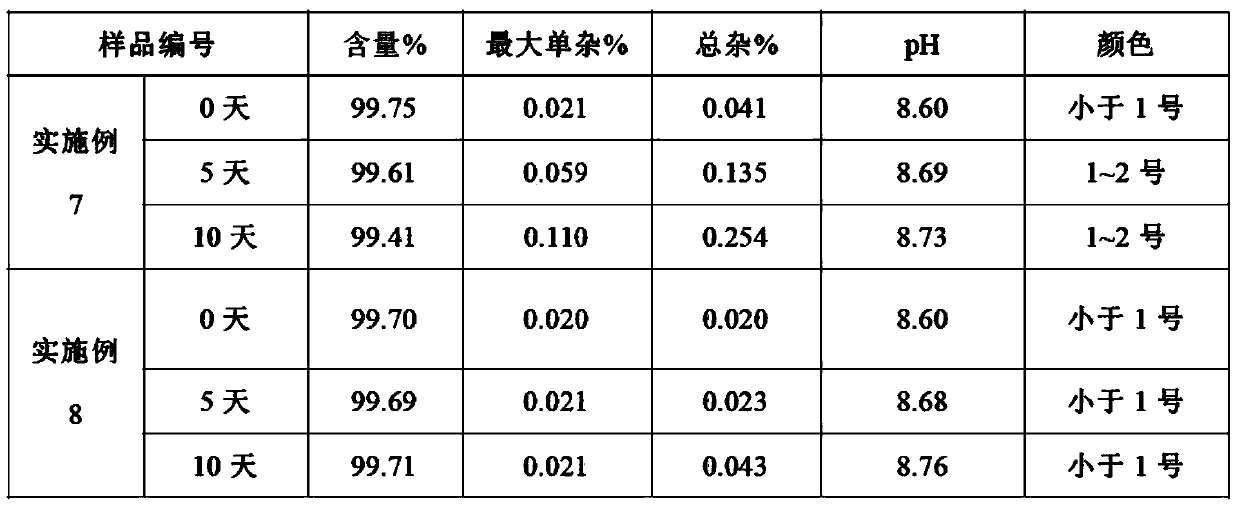

Embodiment 7-8

[0045] Formulation and preparation conditions of table 3 embodiment 7-8 Dexibuprofen composition

[0046] test

Raw materials

The molar ratio of

concentration

Sterilization conditions

Whether to fill nitrogen

Example 7

Dexibuprofen: Arginine

1:1.30

100mg / ml

121℃ damp heat

N

[0047] Example 8

Dexibuprofen: Arginine

1:1.30

100mg / ml

121℃ damp heat

Y

[0048] 1. Weigh the prescribed amount of arginine and ibuprofen;

[0049] 2. Dissolve arginine with an appropriate amount of water for injection (about 80ml) until it is clear and transparent, add the prescribed amount of Dexibuprofen, and stir until it is completely dissolved;

[0050] 3. Add an appropriate amount of activated carbon, stir for 15 minutes, and decarbonize by filtering with a 0.45 μm filter membrane.

[0051] 4. Dilute to full volume, filter with 0.22μm filter membrane, fill, 4ml / bottle, and seal.

[0052] 5. Steri...

Embodiment 8-10

[0059] Formulation and preparation conditions of table 5 embodiment 8-10 Dexibuprofen composition

[0060] test

Raw materials

The molar ratio of

Sterilization conditions

Whether to fill nitrogen

Example 8

Dexibuprofen: Arginine

1:1.30

121℃ damp heat for 15min

Y

Example 9

Dexibuprofen: Arginine

1:1.30

121°C damp heat for 8 minutes

Y

[0061] Example 10

Dexibuprofen: Arginine

1:1.30

115°C damp heat for 30min

Y

[0062] 1. Weigh the prescribed amount of arginine and ibuprofen;

[0063] 2. Dissolve arginine with an appropriate amount of water for injection (about 80ml) until it is clear and transparent, add the prescribed amount of Dexibuprofen, and stir until it is completely dissolved;

[0064] 3. Add 0.5% activated carbon, stir for 15 minutes, and remove carbon by filtering with a 0.45 μm filter membrane.

[0065] 4. Dilute to full volume, filter with 0.22μm filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com