a mist remover

A technology of oil collection tank and cyclone separator, which is applied in the direction of chemical instruments and methods, dispersed particle separation, combined devices, etc., which can solve the problems of inconvenient operation of degreasing mist and the inability to remove oil slicks in real time, and achieve the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

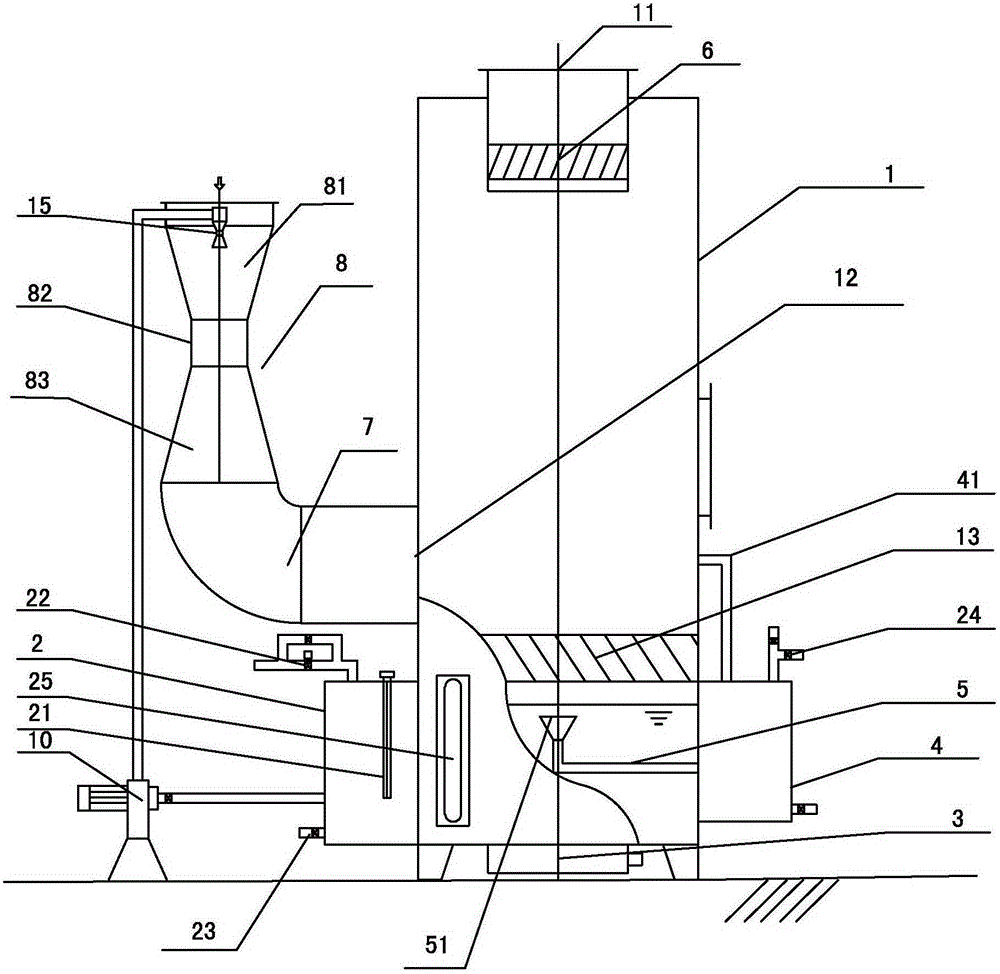

[0018] Embodiment one: if figure 1 Shown, a kind of degreasing mist device comprises cyclone separator 1, air intake mechanism, the water spray mechanism and water tank 2 that are used to spray water at the air inlet place of air intake mechanism, and water tank 2 is positioned at cyclone separator 1 below and It communicates with the bottom of the cyclone separator 1, the cyclone separator 1 is provided with an oil discharge mechanism, the bottom of the water tank 2 is provided with an ultrasonic emission unit 3 that transmits ultrasonic waves to the inside of the water tank 2, and the oil discharge mechanism includes an oil collection tank 4 and a first pipeline 5, The first pipeline 5 communicates with the water tank 2 and the oil collection tank 4. The port 51 of the first pipeline 5 located in the water tank 2 is an oil inlet. The oil tank 4 and the cyclone separator 1 are connected through a pipeline 41 to ensure that the air pressure in the two is the same, so that the ...

Embodiment 2

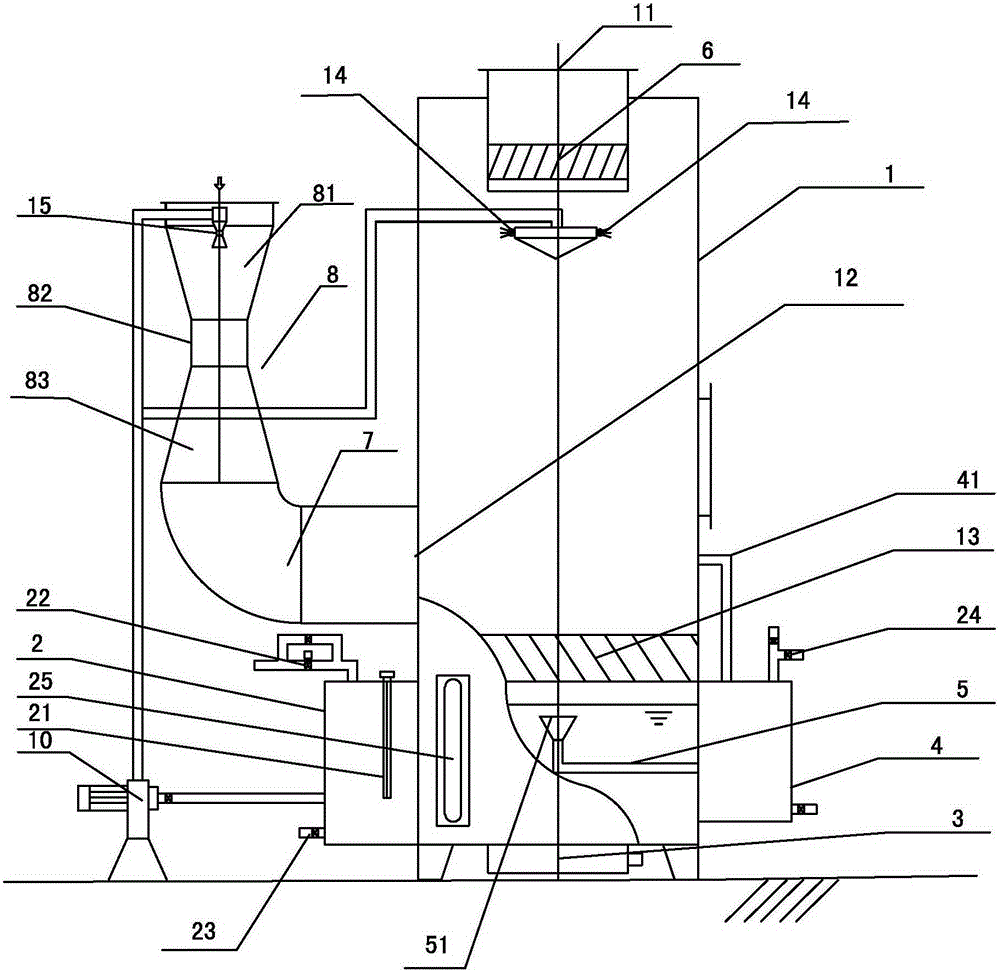

[0024] Embodiment two: if figure 2 As shown, the present embodiment is provided with a plurality of nozzles 14 in a circle in the cyclone separator 1 on the basis of Embodiment 1, and the plurality of nozzles 14 are respectively connected to the output end of the high-pressure water pump 10, and the plurality of nozzles 10 are set At the output 11 close to the cyclone 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com