Top strap for vehicle

A roof strip and vehicle technology, which is applied to vehicle parts, transportation and packaging, etc., can solve the problem of easy falling off of the support frame and rubber layer, and achieve the effect of ensuring strength, improving service life, and not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

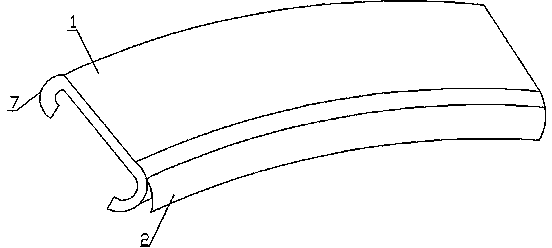

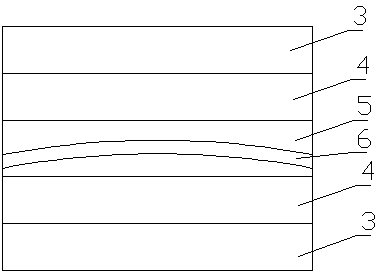

[0023] The roof strip of this embodiment includes a composite rubber layer, the two ends of the composite rubber layer are bent to form a bending part for clamping with the roof of the vehicle, and the bending part is connected with spokes for decoration and sealing. The rubber layer is composed of a silicone rubber layer, an EPDM rubber layer and a nitrile rubber layer. The two sides of the silicone rubber layer are covered with an EPDM rubber layer, and the two outer sides of the EPDM The nitrile rubber layer is sandwiched with a stainless steel wire mesh layer.

Embodiment 2

[0025] The roof strip of this embodiment includes a composite rubber layer, the two ends of the composite rubber layer are bent to form a bending part for clamping with the roof of the vehicle, and the bending part is connected with spokes for decoration and sealing. The rubber layer is composed of a silicone rubber layer, an EPDM rubber layer and a nitrile rubber layer. The two sides of the silicone rubber layer are covered with an EPDM rubber layer, and the two outer sides of the EPDM The nitrile rubber layer is sandwiched with a stainless steel wire mesh layer. The stainless steel wire layer is an arc structure, and the arc opening is set downward.

Embodiment 3

[0027] The roof strip of this embodiment includes a composite rubber layer, the two ends of the composite rubber layer are bent to form a bending part for clamping with the roof of the vehicle, and the bending part is connected with spokes for decoration and sealing. The rubber layer is composed of a silicone rubber layer, an EPDM rubber layer and a nitrile rubber layer. The two sides of the silicone rubber layer are covered with an EPDM rubber layer, and the two outer sides of the EPDM The nitrile rubber layer is sandwiched with a stainless steel wire mesh layer. The stainless steel wire layer is an arc structure, and the arc opening is set downward. The silicone rubber layer and the EPDM rubber layer are provided with through holes, and the through holes of the silicone rubber layer are arranged in correspondence with the through holes of the EPDM rubber layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com