Resistance strain gauge

A resistance strain gauge and sensitive grid technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of large dispersion of sensitivity coefficient, small peripheral surface area of grid wire, poor accuracy, etc., to achieve good heat dissipation, The effect of small dispersion of sensitivity coefficient and accurate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

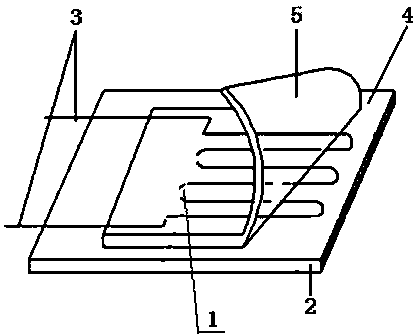

[0014] Such as figure 1 As shown, a strain gauge of the present invention includes a base 2, the upper panel of the base 2 is pasted with a sensitive grid 1 through an adhesive 4, and the left and right ends of the sensitive grid 1 are respectively connected with lead wires 3. The cross-section of the sensitive grid 1 is set as a rectangle, and a surface covering 5 is set on the sensitive grid 1 .

[0015] Further, the sensitive gate 1 is made of semiconductor material.

[0016] Further, the sensitive grid 1 is a foil sheet.

[0017] In the resistance strain gauge of the present invention, the section of the sensitive grid is rectangular, so the surrounding surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com