Wind driven generator set failure feature extracting method based on sparse decomposition

A wind turbine, sparse decomposition technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as cross influence of fault features, large background noise, and difficulty in extracting fault features, so as to achieve simple calculation and improve economic and social benefits. , The effect of facilitating the practical application of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] The vibration acceleration signal in the vertical direction of the output shaft of the parallel shaft gearbox is collected from a wind turbine drive chain fault diagnosis test bench. The gear at the high-speed end of the parallel shaft gearbox has 23 teeth, and the large gear on the intermediate shaft meshing with it is a faulty gear with prefabricated pitting on the teeth. The gear has 83 teeth and the meshing transmission ratio is 1:3.61.

[0053] After obtaining the vibration signal a(t), proceed as follows:

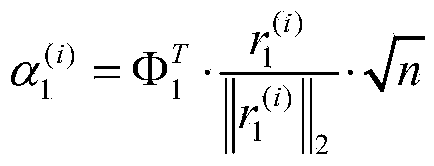

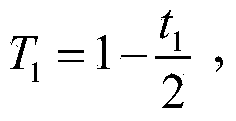

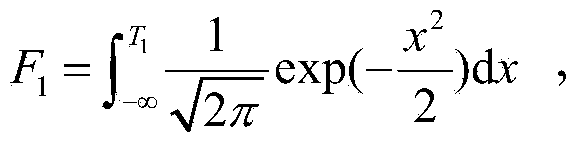

[0054] 1. For the tested vibration signal, according to the different morphological components of the signal, iteratively sparsely decomposes and reconstructs the signal to extract the harmonic component, impact component and margin; this case adopts the combination of Morphological Component Analysis (MCA) Stepwise Orthogonal Matching Pursuit (StagewiseOrthogonalMatchingPursuit, StOMP), and the use of discrete cosine transform (DCT) dictionary to extract harmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com