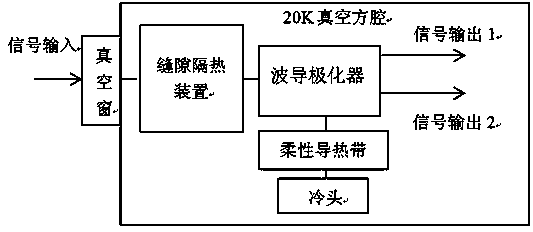

X-waveband refrigeration polarizer cooling structure device

A cooling structure and polarizer technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of reduced signal reception quality, increased noise level, etc., to reduce the equivalent noise temperature and increase the G/T value , good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

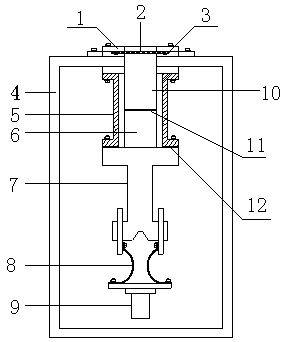

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] Such as figure 1 , figure 2 The shown X-band refrigeration polarizer cooling structure device includes a polarizer 7 and a slot waveguide, and the slot waveguide includes a waveguide upper cavity 10 and a waveguide lower cavity 6, and the waveguide upper cavity 10 and the waveguide lower cavity There is a gap 11 between the opposite ports of the cavity 6 . One end of the polarizer 7 is fixedly connected to the cold head 9 of the refrigerator through a conduction tape 8 , and the other end is fixedly connected to the other end of the waveguide lower cavity 6 opposite to the waveguide upper cavity 10 . The slot waveguide, polarizer 7 and refrigerator cold head 9 are located in the vacuum cavity. The other end of the waveguide upper chamber 10 opposite to the waveguide lower chamber 6 is fixedly connected with the vacuum chamber. By connecting the polarizer 7 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com